Preparation method of tannic acid modification-based leaf surface affiliative pesticide nano microcapsules

A technology of nano-microcapsules and tannic acid is applied in the directions of botanical equipment and methods, biocides, plant growth regulators, etc., to achieve the effects of improving deposition efficiency, stable and reliable product quality, and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

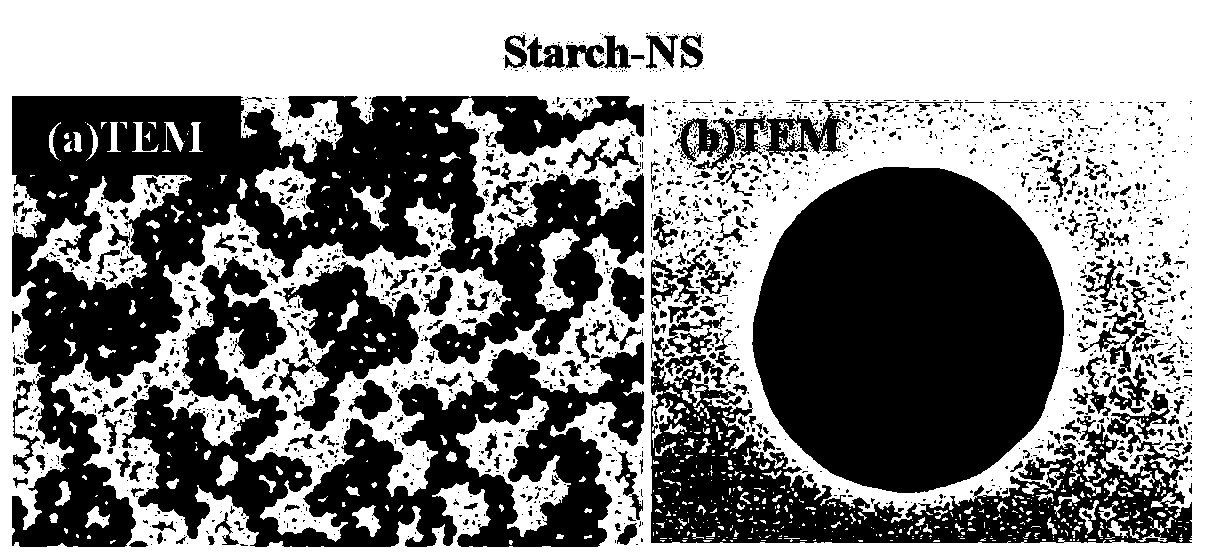

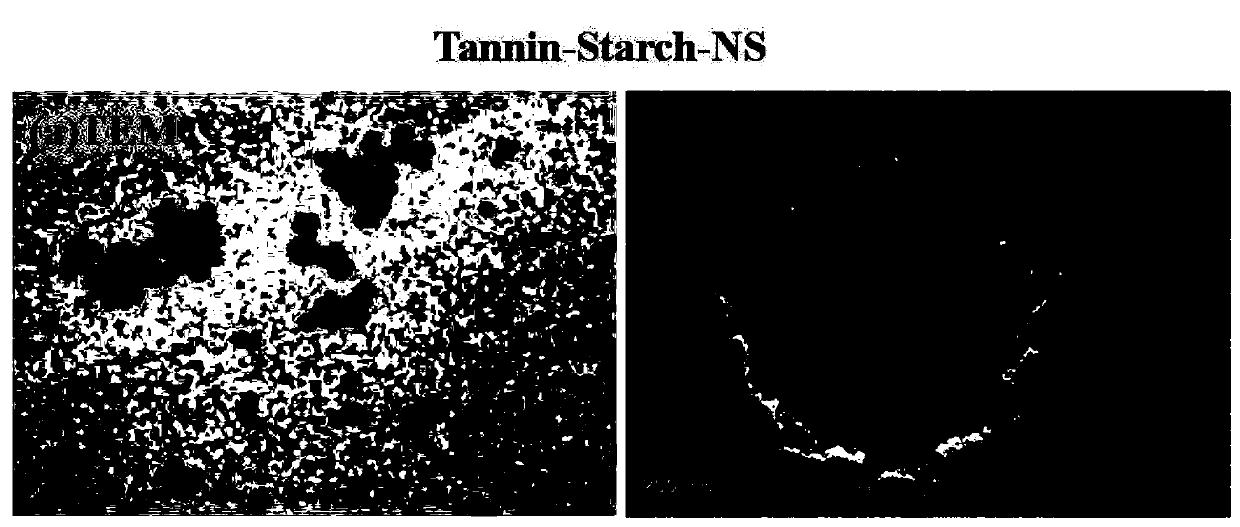

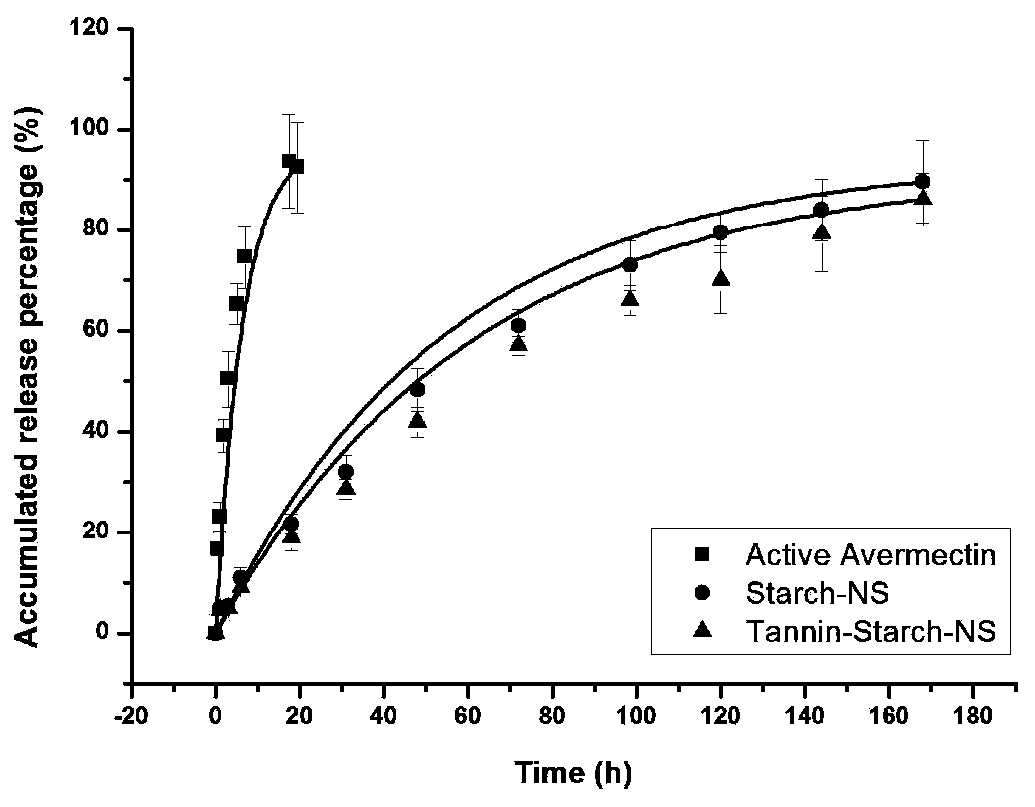

Image

Examples

Embodiment 1

[0031] Embodiment 1: the preparation of modified starch acetate

[0032] Weigh 60g of cornstarch and disperse evenly in 80mL of glacial acetic acid, then add 100mL of cooled acetic anhydride to it, after 15 minutes, add 1.0g of p-toluenesulfonic acid into the reaction solution, and stir the reaction mixture at 80°C for 3 hours , and poured into deionized water. The mixture was washed continuously with deionized water, and finally the solid was dried overnight in a vacuum oven at 50° C. to obtain a white powder, which was modified starch acetate.

Embodiment 2

[0033] Example 2: Preparation of Foliar Affinity Pesticide Nanocapsules

[0034] Specific steps are as follows:

[0035] Polyvinyl alcohol is dissolved in water to obtain an aqueous phase solution with a concentration of 0.5% by weight;

[0036] Abamectin and the modified starch acetate prepared in Example 1 are dissolved in methylene chloride, wherein the weight ratio of starch acetate and Abamectin is 1:1, to obtain an organic phase solution;

[0037] According to the volume ratio of the organic phase solution to the aqueous phase solution of 1:3, add the above organic phase solution into the above aqueous phase solution, stir and mix evenly to obtain the primary emulsion;

[0038] Use 300W to further ultrasonically emulsify the primary emulsion for 3 minutes; then stir at 500 rpm at room temperature until the organic solvent is completely volatilized to obtain pesticide nanospheres;

[0039] The ferric chloride aqueous solution with a concentration of 1.0% by weight is ad...

Embodiment 3

[0040] Example 3: Preparation of Foliar Affinity Pesticide Nanocapsules

[0041] Specific steps are as follows:

[0042] Polyvinyl alcohol is dissolved in water to obtain an aqueous phase solution with a concentration of 2.0% by weight;

[0043] The modified starch acetate prepared in emamectin benzoate and embodiment 1 is dissolved in methylene chloride, wherein the weight ratio of starch acetate and emamectin benzoate is 1 : 5, obtain organic phase solution;

[0044] According to the volume ratio of the organic phase solution to the aqueous phase solution of 1:10, add the above organic phase solution into the above aqueous phase solution, stir and mix evenly to obtain the primary emulsion;

[0045] Use 300W to further ultrasonically emulsify the primary emulsion for 5 minutes; then stir at 1000rpm at room temperature until the organic solvent is completely volatilized to obtain pesticide nanocapsules;

[0046] The ferric chloride aqueous solution with a concentration of 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com