Preparation method of perovskite solar cell

A solar cell and perovskite technology, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of unfavorable large-scale production and low coating efficiency, achieve uniform and stable filling effect, improve coating efficiency, and improve filling efficiency. uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

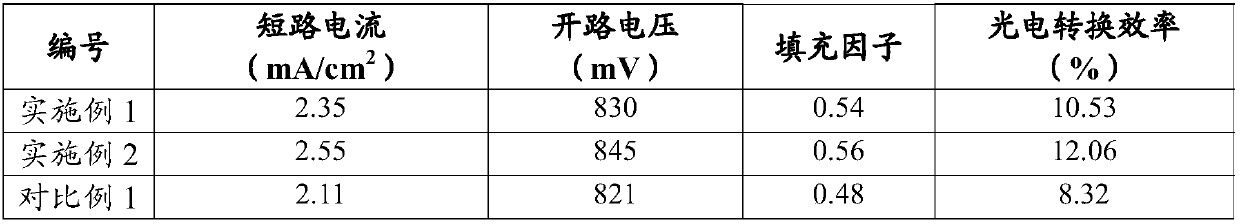

Embodiment 1

[0028] Mix 0.438g of methylamine iodide and 1.314g of lead iodide, dissolve in 3mL of γ-butyrolactone, and stir evenly at 60°C to obtain CH 3 NH 3 PB 3 precursor solution.

[0029] A fluorine-doped tin oxide (FTO) conductive glass with a length of 100 mm and a width of 100 mm was laser etched into nine sub-cells connected in series. Clean the conductive glass sequentially with cleaning agent ( III cuvette cleaning agent, 2wt% deionized water solution), distilled water and absolute ethanol for ultrasonic cleaning for 10 minutes. Place the cleaned conductive glass on the hot stage, and use a titanium plate as a shield to block the counter electrode area. Heat to 450°C, then spray the ethanol solution of diisopropyl di(acetylacetonate) titanate (the volume ratio of diisopropyl di(acetylacetonate) titanate to ethanol is 1:39) on the conductive glass The surface, after decomposition, forms a dense layer of titanium dioxide. Remove the barrier of the counter electrode area, d...

Embodiment 2

[0032] Mix 0.438g of methylamine iodide and 1.314g of lead iodide, dissolve in 3mL of γ-butyrolactone, and stir evenly at 60°C to obtain CH 3 NH 3 PB 3 precursor solution.

[0033] A fluorine-doped tin oxide (FTO) conductive glass with a length of 100 mm and a width of 100 mm was laser etched into nine sub-cells connected in series. Clean the conductive glass sequentially with cleaning agent ( III cuvette cleaning agent, 2wt% deionized water solution), distilled water and absolute ethanol for ultrasonic cleaning for 10 minutes. Place the cleaned conductive glass on the hot stage, and use a titanium plate as a shield to block the counter electrode area. Heat to 450°C, then spray the ethanol solution of diisopropyl di(acetylacetonate) titanate (the volume ratio of diisopropyl di(acetylacetonate) titanate to ethanol is 1:39) on the conductive glass The surface, after decomposition, forms a dense layer of titanium dioxide. Remove the barrier of the counter electrode area, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com