A hot-swap-based automatic disassembly split chassis system and working method

A technology of automatic disassembly and working methods, which is applied in the direction of digital processing power distribution, instruments, calculations, etc., and can solve the problems of inconvenient change and use of functional modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

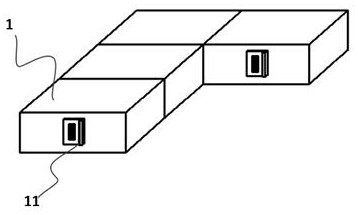

[0066] This embodiment provides a hot-swap-based automatic detachable split chassis system, including: several chassis units 1 and a controller 2 .

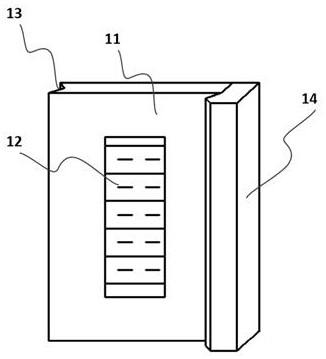

[0067] The chassis units 1 are independent of each other. At least one connecting device 11 is arranged on the chassis unit 1 , and a data interface device 12 is arranged in the connecting device 11 . The cabinet units 1 are connected to each other by connection means 11 .

[0068] The chassis unit 1 is a single box body, and the chassis unit 1 may also include a cooling device, an installation opening, etc., and the cooling module may be a fan or an air outlet for heat dissipation of the chassis unit 1 . The installation port is used for installing or removing the devices in the case unit 1 .

[0069] The connecting device 11 further includes a locking device 14 , a locking interface 13 is provided on one side of the connecting device 11 , and the locking device 14 is used for locking with the locking interface 13 . The locki...

Embodiment 2

[0115] This embodiment is a method embodiment of the first embodiment above.

[0116] A working method of a hot-swap-based automatic disassembly split chassis system, comprising:

[0117] The main chassis unit 1 and the auxiliary chassis unit 1 are connected to each other through a connecting device 11 .

[0118] The functional modules in the main chassis unit 1 exchange data with the functional modules in the auxiliary chassis unit 1 through the data interface device 12 of the connection device 11 .

[0119] If the user needs to use part of the functions of the chassis unit 1 , the controller 2 provides the user with a choice of the chassis unit 1 .

[0120] The controller 2 outputs unlocking signals to the locking devices 14 of other cabinet units 1 according to the cabinet unit 1 selected by the user.

[0121] The locking device 14 that receives the unlocking signal is unlocked, and the corresponding chassis unit 1 is disengaged.

[0122] As a preferred mode of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com