Special plastic plate capable of improving diamond wire cutting large system and preparation method thereof

A technology of diamond wire cutting and plastic plate, which is applied in the field of plastic plate preparation, can solve the problems of affecting the cutting process, the conductivity, the large fluctuation range of pH value, and the inability to maintain the stability of the large circulation system, so as to save energy consumption and improve the tensile strength. Good, easy to recycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

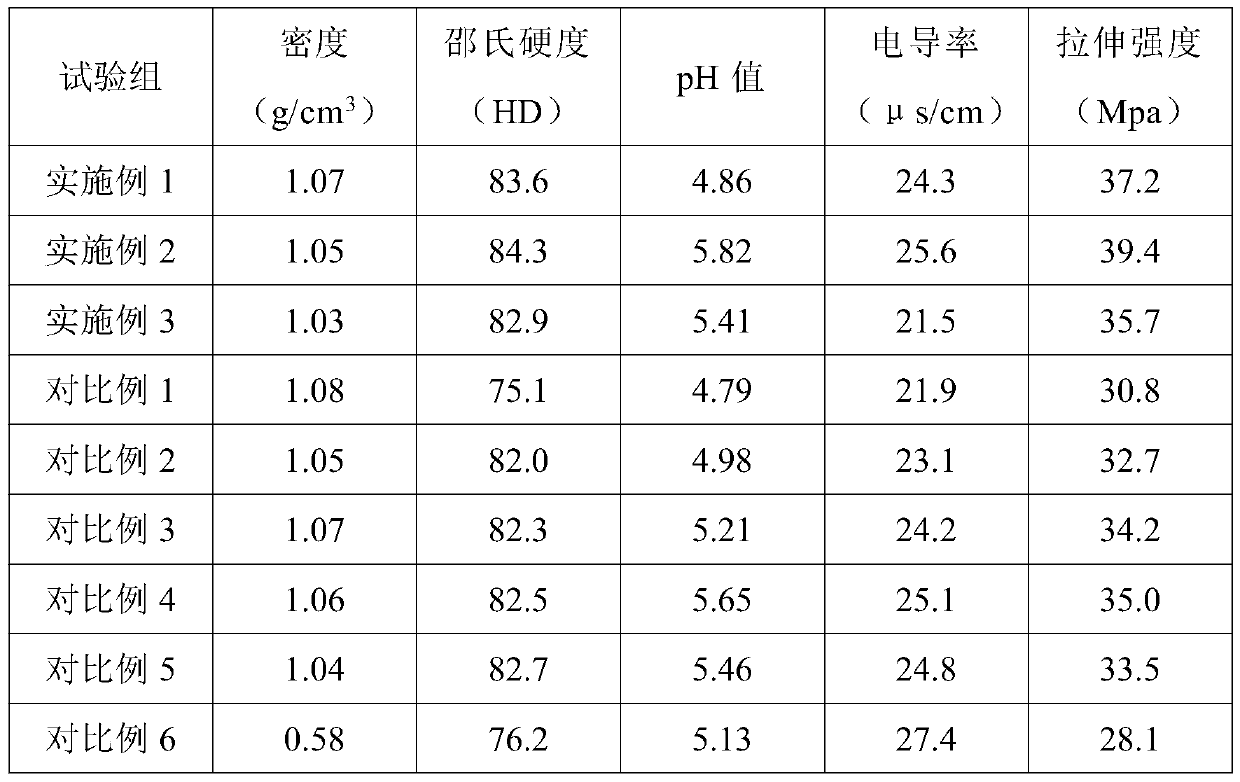

Examples

Embodiment approach

[0026] 1. Experimental equipment

[0027] Mixer (with adjustable speed stirring device), twin-screw extrusion granulator (with automatic temperature control device, cooling device, vacuum device), dryer (with adjustable speed stirring device, with automatic temperature control device, cooling device), single-screw extrusion molding machine (with automatic temperature control device, cooling device, vacuum pumping device).

[0028] 2. Preparation before the experiment

[0029] Clean and wipe the mixer, twin-screw extrusion granulation, dryer, and single-screw extrusion molding machine to ensure that there are no other materials or impurities that affect the reaction.

[0030] 3. The preparation formula of the special plastic plate that can improve the large diamond wire cutting system: in mass percentage, including

[0031] ABS resin 65%-90%, PMMA resin 5%-30%, compatibilizer 1%-10%, EAA resin 1%-10%, scale inhibitor 0.6%-1.5%, antioxidant 0.2%-1% , lubricant 0.3%-2%, surfac...

Embodiment 1

[0044] 1. Experimental equipment

[0045] Mixer (with adjustable speed stirring device), twin-screw extrusion granulator (with automatic temperature control device, cooling device, vacuum device), dryer (with adjustable speed stirring device, with automatic temperature control device, cooling device), single-screw extrusion molding machine (with automatic temperature control device, cooling device, vacuum pumping device).

[0046] 2. Preparation before the experiment

[0047] Clean and wipe the mixer, twin-screw extrusion granulation, dryer, and single-screw extrusion molding machine to ensure that there are no other materials or impurities that affect the reaction.

[0048] 3. The preparation formula of the special plastic plate that can improve the diamond wire cutting large system: in mass percentage, including ABS resin 70.3%, PMMA resin 20%, compatibilizer 2.6%, EAA resin 4.2%, scale inhibitor 0.8 %, antioxidant 0.7%, lubricant 1%, surfactant 0.4%;

[0049] Described c...

Embodiment 2

[0059] 1. Experimental equipment

[0060] Mixer (with adjustable speed stirring device), twin-screw extrusion granulator (with automatic temperature control device, cooling device, vacuum device), dryer (with adjustable speed stirring device, with automatic temperature control device, cooling device), single-screw extrusion molding machine (with automatic temperature control device, cooling device, vacuum pumping device).

[0061] 2. Preparation before the experiment

[0062] Clean and wipe the mixer, twin-screw extrusion granulation, dryer, and single-screw extrusion molding machine to ensure that there are no other materials or impurities that affect the reaction.

[0063] 3. The preparation formula of the special plastic plate that can improve the large diamond wire cutting system: in mass percentage, including ABS resin 76.4%, PMMA resin 15%, compatibilizer 3%, EAA resin 3%, scale inhibitor 1% , antioxidant 0.5%, lubricant 0.8%, surfactant 0.3%;

[0064] Described compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com