Circulating cooling water treatment equipment and circulating cooling water treatment method

A technology for circulating cooling water and treatment equipment, applied in water/sewage treatment equipment, water/sewage treatment, natural water treatment, etc. Solving problems, problems such as not being able to use at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

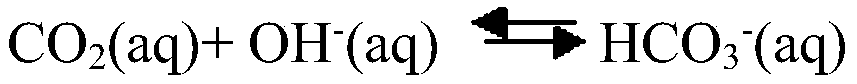

Method used

Image

Examples

Embodiment 1

[0083] Central air-conditioning circulating cooling water system, circulating water volume 850m 3 / h, system volume 50m 3 , Supplement municipal tap water. Set up 2 sets of electrochemical side-flow water treatment equipment, each with a treatment volume of 25m 3 / h, each working current is 30A. In the cooling season of 2018, the control of scaling and corrosion problems met the specified requirements, but the microorganisms were difficult to control. Bacteria and algae grew in the water body, especially on the outer edge of the cooling tower packing, where moss grew. The water quality analysis data are shown in Table 1. Among them, the cumulative removal rate of calcium hardness is 69% (calcium hardness of supplemented water * chloride ion concentration ratio - calcium hardness of circulating water, the difference is divided by the calcium hardness of supplemented water * chloride ion ratio, and the cumulative removal rate is obtained). Residual chlorine in circulating wat...

Embodiment 2

[0091] The circulating cooling water system of the welding workshop of the automobile factory, the circulating water volume is 1050m 3 / h, system volume 500m 3 , with an average evaporation rate of 0.5%, supplemented with municipal tap water. Set up 2 sets of electrochemical side-flow water treatment equipment, each with a treatment volume of 20m 3 / h, each working current is 20A. There is no scale phenomenon in the circulating cooling water system, the microorganisms are within the control range, and the corrosion problem is prominent.

[0092] Refer to Table 3 for the water quality of the supplementary water. The LSI of the supplementary water is negative, and the RSI is greater than 6, indicating a strong corrosion tendency; after concentration to 6-8 times, the RSI of the circulating water is still greater than 6, indicating a corrosion tendency. The carbon steel coupon test also shows that there is corrosion in the circulating water. Since July 3, 2017, each electroch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com