A screw conveying device

A screw conveying device and spiral technology, applied in the field of conveying devices, can solve problems such as poor adaptability, inconvenient use, and inability to turn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

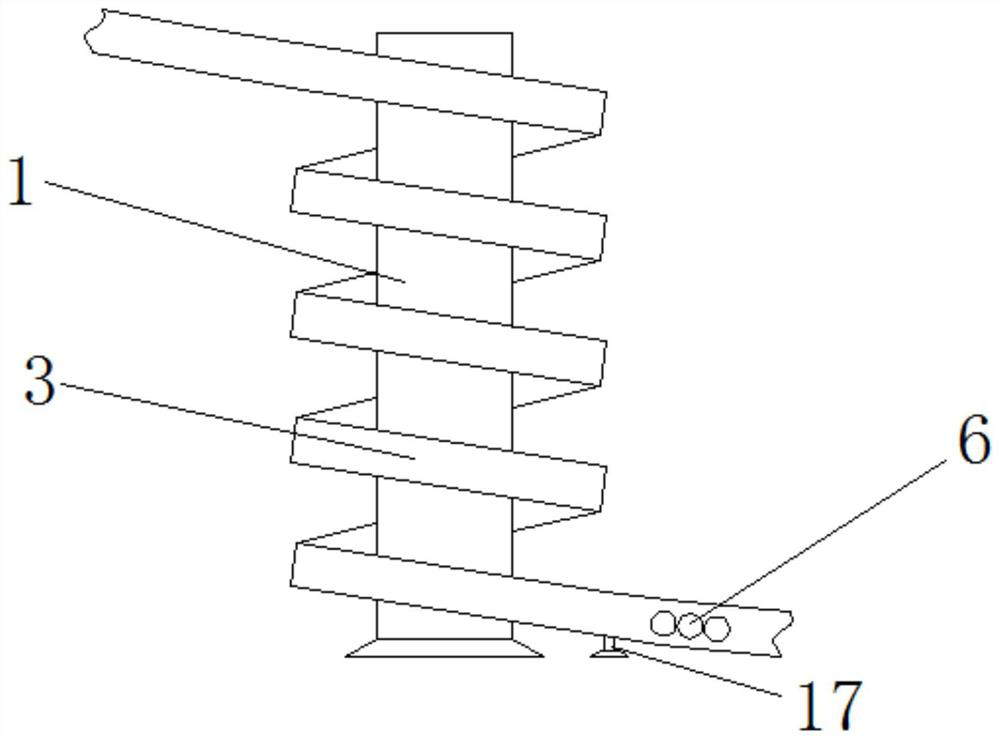

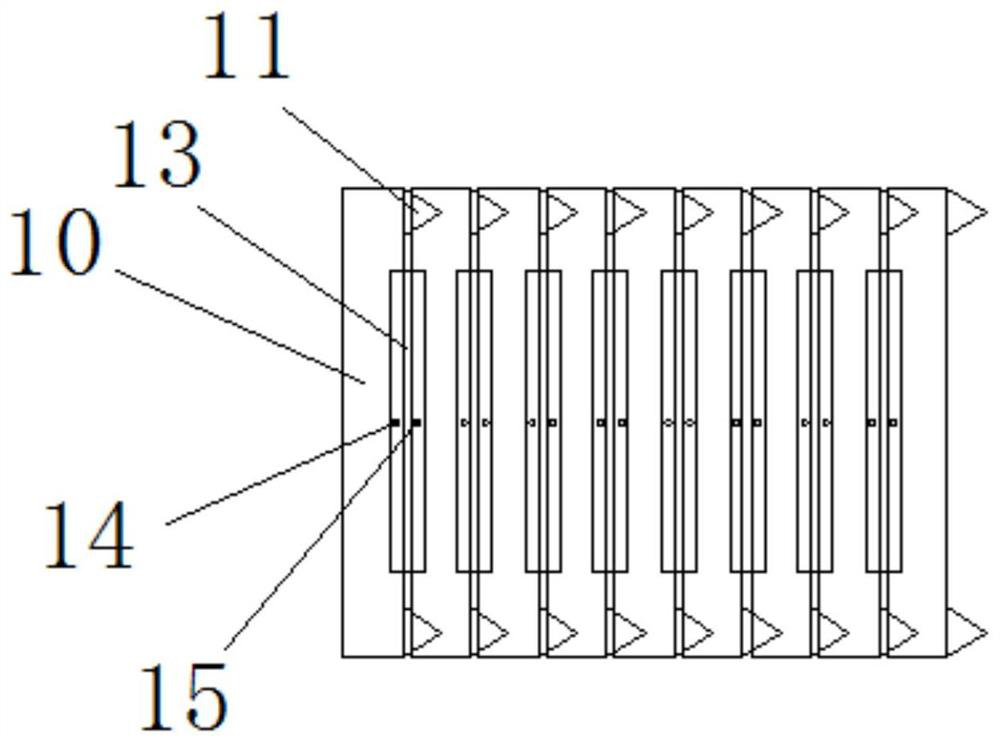

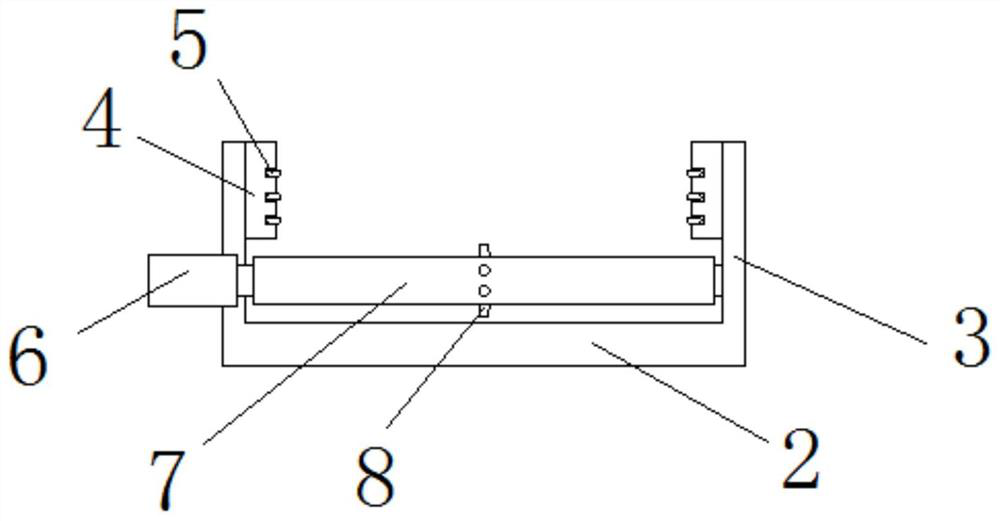

[0024] Example: such as Figure 1-7 As shown, a screw conveying device includes: a column 1, a soft rubber plate 10 and a connecting plate 13;

[0025] The outer side of the column 1 is wound with a spiral slide 2, the tops of both sides of the spiral slide 2 are fixedly connected with side plates 3, and the lower parts of the side plates 3 are rotatably connected with a number of driven rollers 9, Equidistantly arranged and distributed on the upper side of the spiral slide 2, a number of drive rollers 7 are rotated between the bottom of the bottom side panels 3 of the spiral slide 2, and the bottom side panels of the spiral slide 2 The side wall of 3 is fixedly installed with several motors 6, and several described motors 6 correspond to several described driving rollers 7 one by one, and the motors provide power to drive the driving rollers to rotate;

[0026] The soft rubber plates 10 and the connecting plates 13 are arranged in several groups, and are distributed at inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com