Machine and method for producing knitted fabric

A technology of knitted fabrics and circular knitting machines, applied in the field of knitted fabrics, capable of solving complex and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

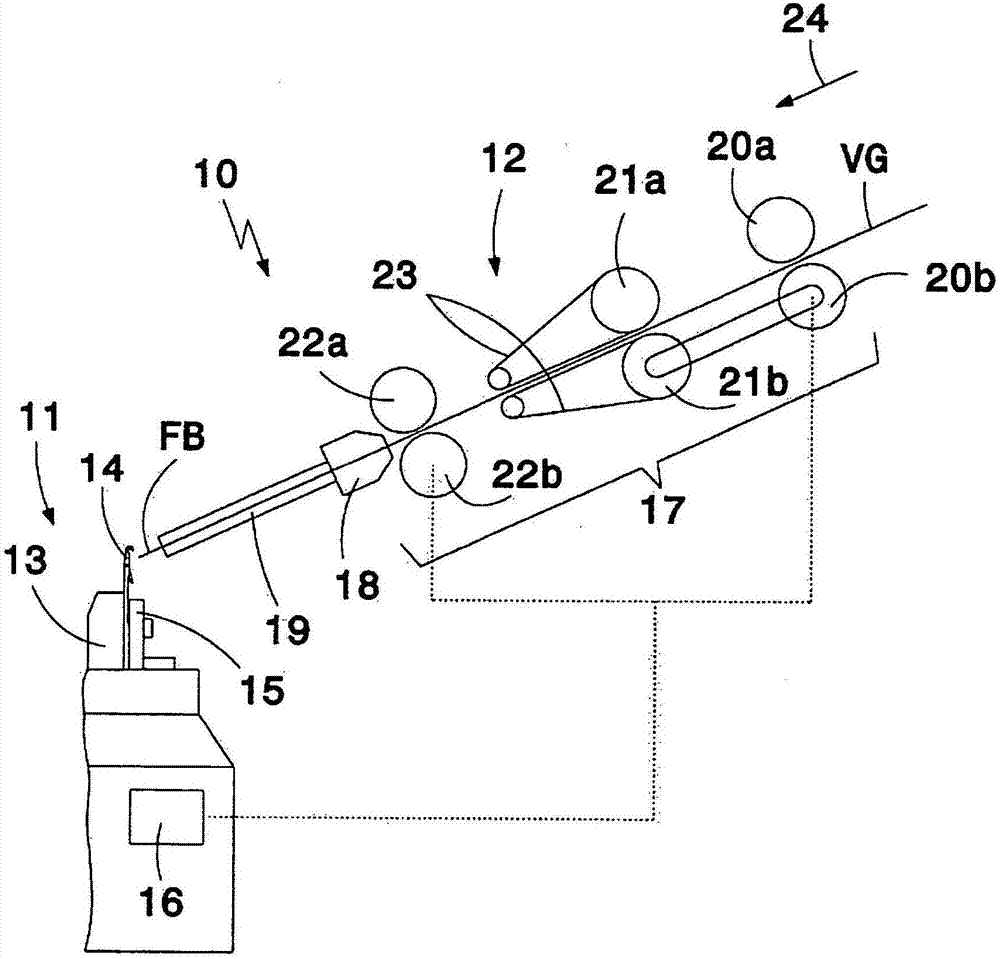

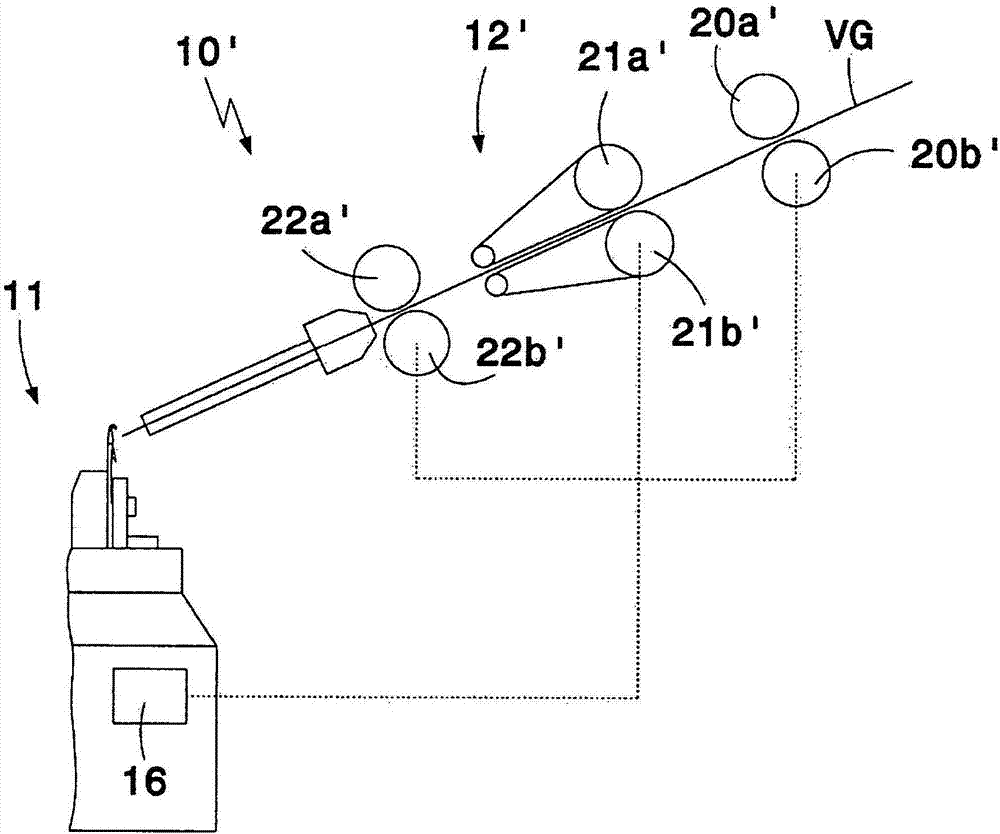

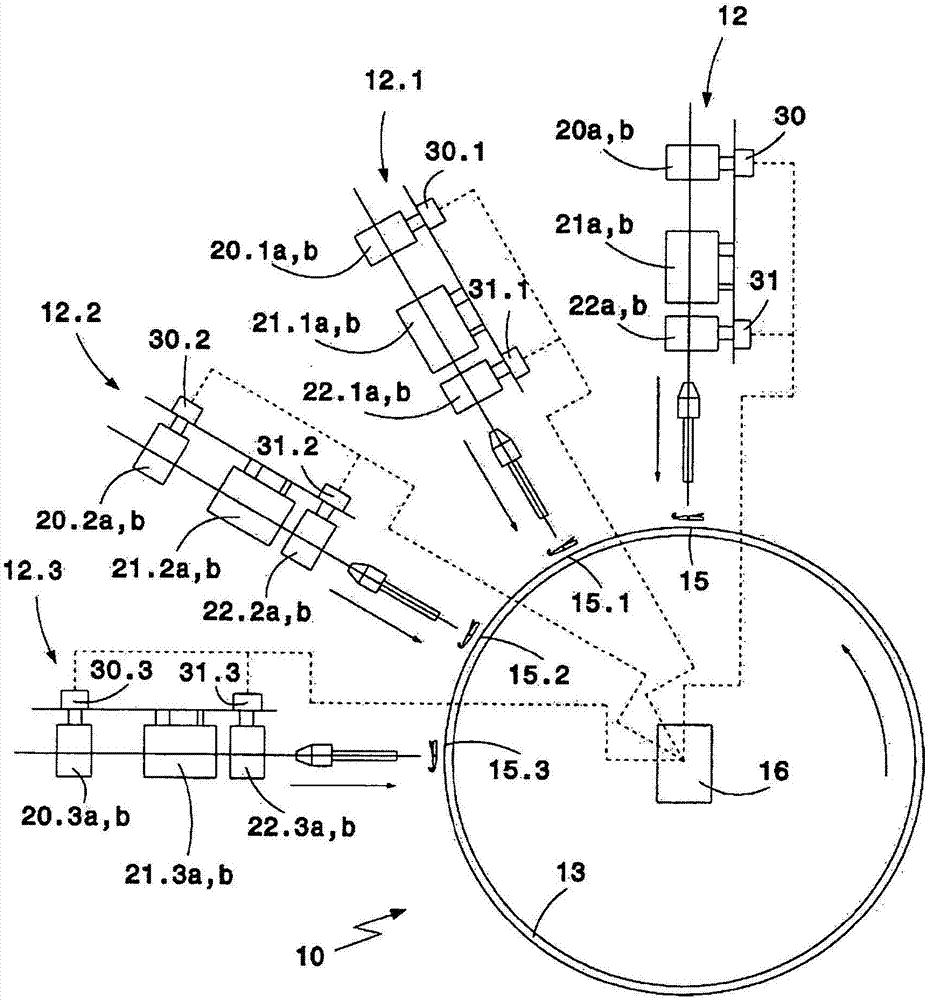

[0042] figure 1 A machine 10 for producing knitted fabrics is shown in a schematic schematic diagram, comprising a circular knitting machine 11 and a spinning device 12 . Shown is a needle cylinder 13 of a circular knitting machine 11 and a stitch forming station 15 , which includes a stitch forming element 14 here in the form of a latch needle, on which the stitch forming element 14 can be ejected in order to form a stitch. Furthermore, a control device 16 for the entire machine 10 is shown.

[0043] A spinning device 12 is assigned to the loop formation site 15 , which comprises a drafting device 17 and a twisting device 18 , which is connected to a delivery pipe 19 . The drafting mechanism 17 has a pair of input rollers 20a, 20b, a pair of apron rollers 21a, 21b and a pair of output rollers 22a, 22b. The double apron 23 is guided on the pair of apron rollers 21a, 21b. In each roller pair 20a, b to 22a, b, the lower roller 20b, 21b and 22b is driven respectively. The dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com