Liquid sample vacuum acquisition device and control method

A liquid sample and collection device technology, applied in the mechanical field, can solve the problems of unreported, inconvenient fluid sampling work, etc., and achieve the effect of accurate quantitative sampling and stable vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

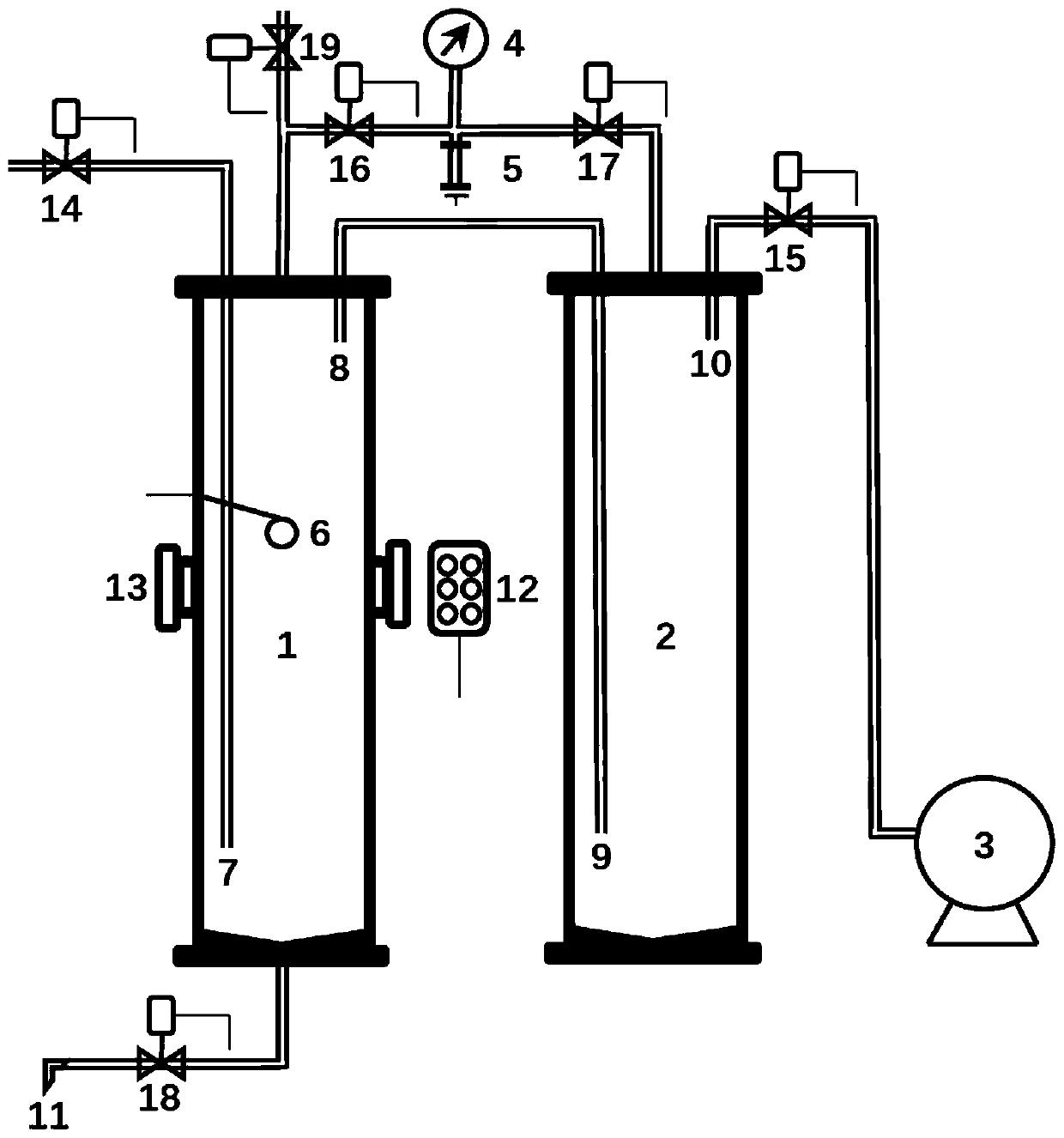

[0021] Embodiment 1: as figure 1 As shown, a liquid sample vacuum collection device is mainly composed of three parts: a sampling unit, a vacuum unit and a control unit.

[0022] The sampling unit is mainly composed of a sampler 1, a vacuum pressure gauge 4, a vacuum pressure sensor 5, a liquid level sensor 6, a liquid inlet pipe 7, an exhaust pipe 8, a sample discharge port 11, a light source 12, a sight glass 13 and a first electric valve 14 , the third electric valve 16, the fourth electric valve 17, the fifth electric valve 18 and the sixth electric valve 19.

[0023] The vacuum unit is mainly composed of a buffer 2, a vacuum pump 3, an intake pipe 9, an exhaust pipe 10 and a second electric valve 15.

[0024] The control unit is mainly composed of a pressure sensor 5, a liquid level sensor 6, a first electric valve 14, a second electric valve 15, a third electric valve 16, a fourth electric valve 17, a fifth electric valve 18, a sixth electric valve 19 and a PLC The com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com