Paint-drying gold foil floor and preparation process

A gold foil and floor technology, applied in metal material coating process, wood layered products, metal layered products, etc., can solve the problems of high cost and maintenance cost, easy cracking, falling off, aging, etc., and achieve excellent plasticity and ductility. The effect of stability, extended use range, and low cost of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

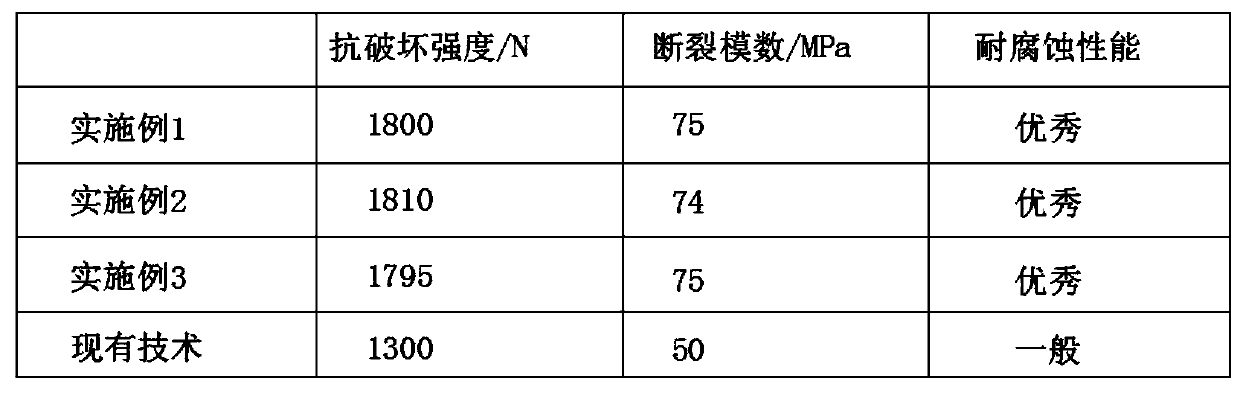

Embodiment 1

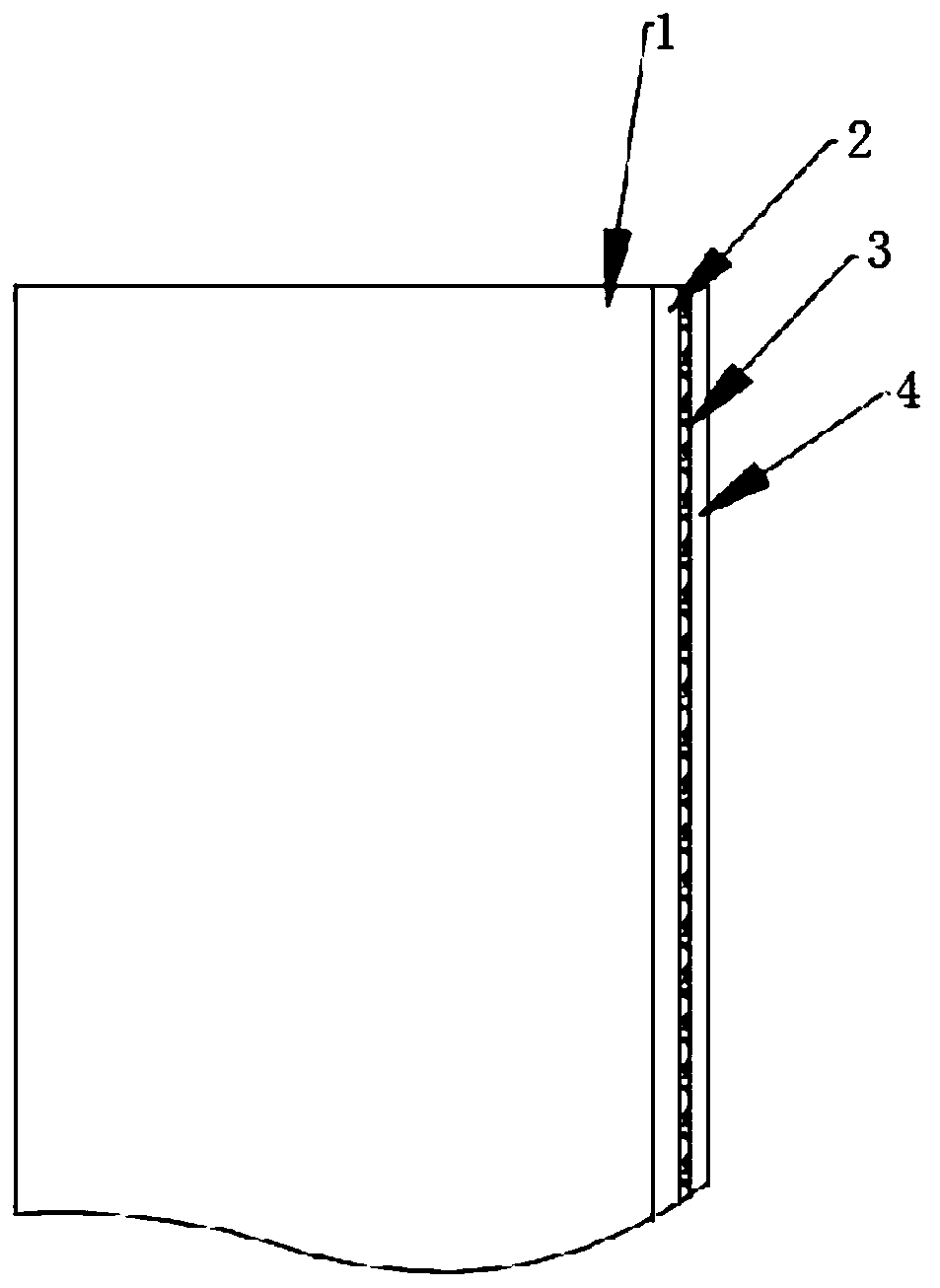

[0039] A preparation process for baking varnish gold leaf floor, specifically comprising the following steps:

[0040] Step 1: Preparation of the main body 1 of the board: specifically, the following steps are included,

[0041]S1. Preparation of inorganic flame retardant layer: Inorganic adhesives and plant fibers are used as raw materials to prepare inorganic flame retardant layers. First, plant straws are crushed into plant fibers and dried and screened, and then the inorganic adhesives are dried and screened. The plant fibers are fed into the periodic mixer, and then the evenly stirred mixture is poured into the prefabricated pavement frame and paved evenly. The pavement thickness is 6mm. Drying treatment is carried out in the dryer, and after the drying treatment is completed, a wide-band sander is used to perform double-sided sanding treatment on the inorganic flame-retardant layer to make the surface of the inorganic flame-retardant layer smooth;

[0042] S2. Preparati...

Embodiment 2

[0062] A preparation process for baking varnish gold leaf floor, specifically comprising the following steps:

[0063] Step 1: Preparation of the main body 1 of the board: specifically, the following steps are included,

[0064] S1. Preparation of inorganic flame retardant layer: Inorganic adhesives and plant fibers are used as raw materials to prepare inorganic flame retardant layers. First, plant straws are crushed into plant fibers and dried and screened, and then the inorganic adhesives are dried and screened. The plant fibers are fed into the periodic mixer, and then the evenly stirred mixture is poured into the prefabricated pavement frame and paved evenly. The pavement thickness is 10mm. Drying treatment is carried out in the dryer, and after the drying treatment is completed, a wide-band sander is used to perform double-sided sanding treatment on the inorganic flame-retardant layer to make the surface of the inorganic flame-retardant layer smooth;

[0065] S2. Prepara...

Embodiment 3

[0085] A preparation process for baking varnish gold leaf floor, specifically comprising the following steps:

[0086] Step 1: Preparation of the main body 1 of the board: specifically, the following steps are included,

[0087] S1. Preparation of inorganic flame retardant layer: Inorganic adhesives and plant fibers are used as raw materials to prepare inorganic flame retardant layers. First, plant straws are crushed into plant fibers and dried and screened, and then the inorganic adhesives are dried and screened. The plant fiber is sent to the periodic mixer, and then the evenly stirred mixture is poured into the prefabricated pavement frame and paved evenly. Drying treatment is carried out in the dryer, and after the drying treatment is completed, a wide-band sander is used to perform double-sided sanding treatment on the inorganic flame-retardant layer to make the surface of the inorganic flame-retardant layer smooth;

[0088] S2. Preparation of veneer reinforcement layer:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com