Breathable sole and production process thereof

A technology of mixed liquid and natural rubber, applied in the direction of sole, footwear, application, etc., can solve the problems of poor air permeability of rubber sole and stuffy feet, etc., and achieve excellent mechanical properties, reduce stuffiness, and improve the effect of air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

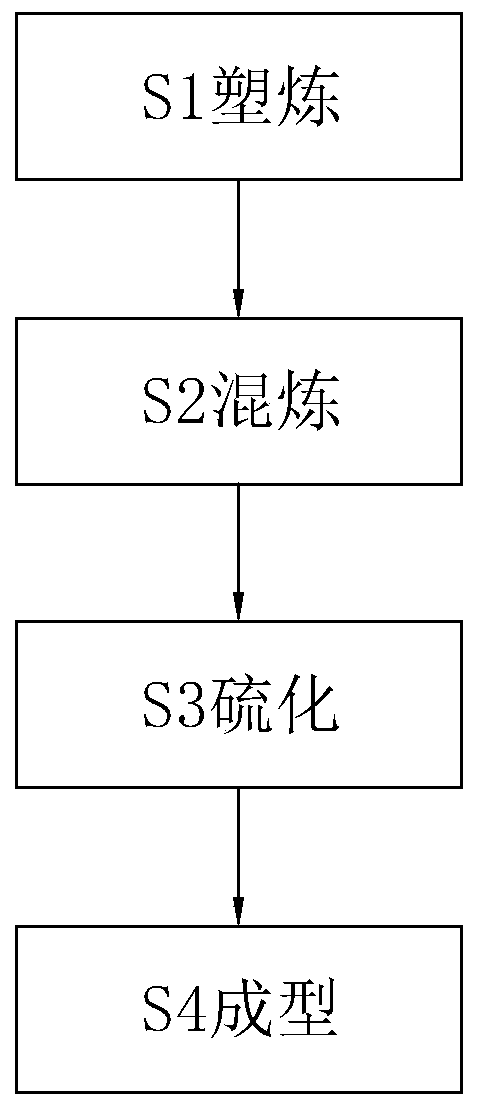

Method used

Image

Examples

Embodiment 1

[0054] A kind of breathable sole, comprises the component of following parts by weight:

[0055] 35 parts of natural rubber;

[0056] 20 parts of EPDM rubber;

[0057] 35 parts of methyl vinyl silicone rubber, molecular weight 600,000, vinyl mass fraction 0.1%;

[0058] POE 10 parts, VA content 28%;

[0059] 4 parts of compatibilizer;

[0060] 1.5 parts of vulcanizing agent, the vulcanizing agent is composed of DCP and sulfur in equal mass ratio;

[0061] Accelerator 1 part, the accelerator is compounded by accelerator M and accelerator TMTD in equal mass ratio;

[0062] 40 parts of filler, the filler includes 50% light calcium carbonate, 30% kaolin, and 20% modified carbon fiber by mass fraction;

[0063] 2 parts of blowing agent H;

[0064] Allantoin 1 part;

[0065] Hydroxy silicone oil 2 parts;

[0066] 0.8 parts of anti-aging agent, anti-aging agent is compounded by anti-aging agent RD and anti-aging agent 4010 in equal mass ratio;

Embodiment 2

[0085] A kind of breathable sole, comprises the component of following parts by weight:

[0086] 45 parts of natural rubber;

[0087] 25 parts of EPDM rubber;

[0088] 45 parts of methyl vinyl silicone rubber, molecular weight 600,000, vinyl mass fraction 0.1%;

[0089] POE 15 parts, VA content 28%;

[0090] 7 parts of compatibilizer;

[0091] 3 parts of vulcanizing agent, the vulcanizing agent is compounded by DCP and sulfur in equal mass ratio;

[0092] Accelerator 1.5 parts, the accelerator is compounded by accelerator M and accelerator TMTD in equal mass ratio;

[0093] 60 parts of filler, the filler includes 50% light calcium carbonate, 30% kaolin, and 20% modified carbon fiber by mass fraction;

[0094] 3 parts of blowing agent H;

[0095] Allantoin 1.5 parts;

[0096] 3 parts of hydroxyl silicone oil;

[0097] 1.5 parts of anti-aging agent, the anti-aging agent is compounded by anti-aging agent RD and anti-aging agent 4010 in equal mass ratio;

[0098] Active z...

Embodiment 3

[0116] A kind of breathable sole, comprises the component of following parts by weight:

[0117] 40 parts of natural rubber;

[0118] 22 parts of EPDM rubber;

[0119] 40 parts of methyl vinyl silicone rubber, molecular weight 600,000, vinyl mass fraction 0.1%;

[0120] POE 12 parts, VA content 28%;

[0121] 5 parts of compatibilizer;

[0122] 2 parts of vulcanizing agent, the vulcanizing agent is compounded by DCP and sulfur in equal mass ratio;

[0123] Accelerator 1.2 parts, the accelerator is compounded by accelerator M and accelerator TMTD in equal mass ratio;

[0124] 50 parts of filler, the filler includes 50% light calcium carbonate, 30% kaolin, and 20% modified carbon fiber by mass fraction;

[0125] 2.5 parts of blowing agent H;

[0126] Allantoin 1.2 parts;

[0127] 2.5 parts of hydroxyl silicone oil;

[0128] Anti-aging agent 1.2 parts, the anti-aging agent is compounded by anti-aging agent RD and anti-aging agent 4010 in equal mass ratio;

[0129] Active ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com