Production method of dual-curing solar glass panel capable of changing color along with scenes

A solar glass, dual-curing technology, used in the production of special varieties of printed matter printing, post-printing, ink and other directions, can solve the problems of coating peeling, poor substrate adhesion, poor weather resistance, etc., to improve adhesion, The effect of low emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Spray 2% neutral surfactant aqueous solution on the glass panel, then brush it mechanically, rinse it with tap water, wash it with deionized water, and finally dry it with hot air at 100°C;

[0038] Screen-print the color-changing ink on the solar glass panel;

[0039] Low-temperature preheating, using IR infrared to heat the solar glass panel coated with the color-changing ink, the heating temperature is 100°C, and the heating time is 12 minutes;

[0040]UV light curing, ultraviolet light irradiates the solar glass panel after low temperature preheating for light curing, the wavelength of ultraviolet light is 390nm, and the energy of ultraviolet light irradiation is 350 mJ / cm2;

[0041] IR post-curing, using IR infrared to heat the UV-cured solar glass panel for post-curing, the heating temperature is 130°C, and the heating time is 12 minutes to obtain a color-changing solar glass panel;

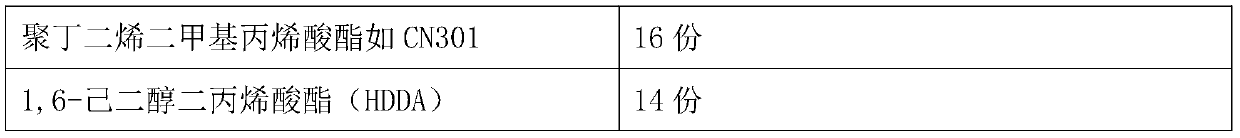

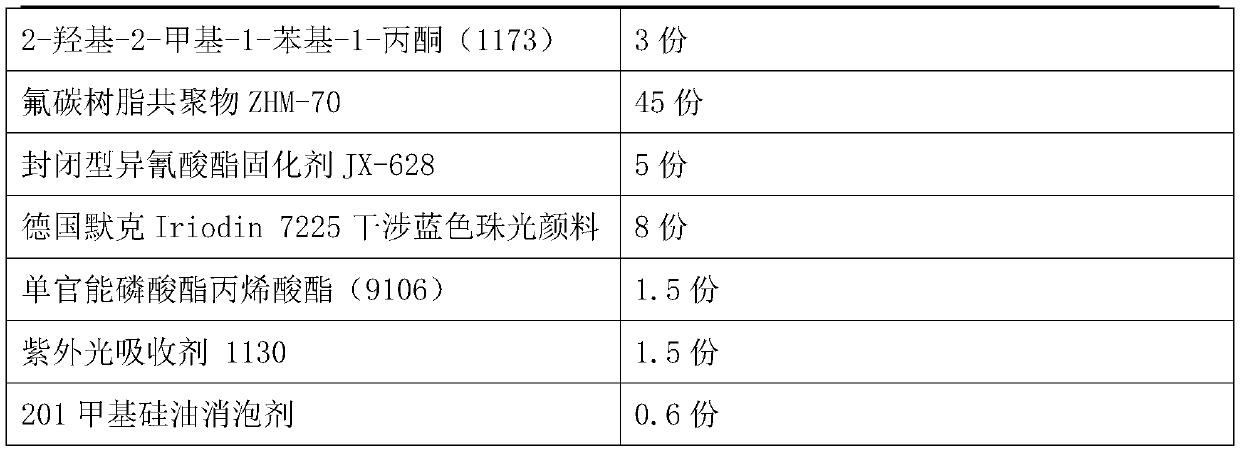

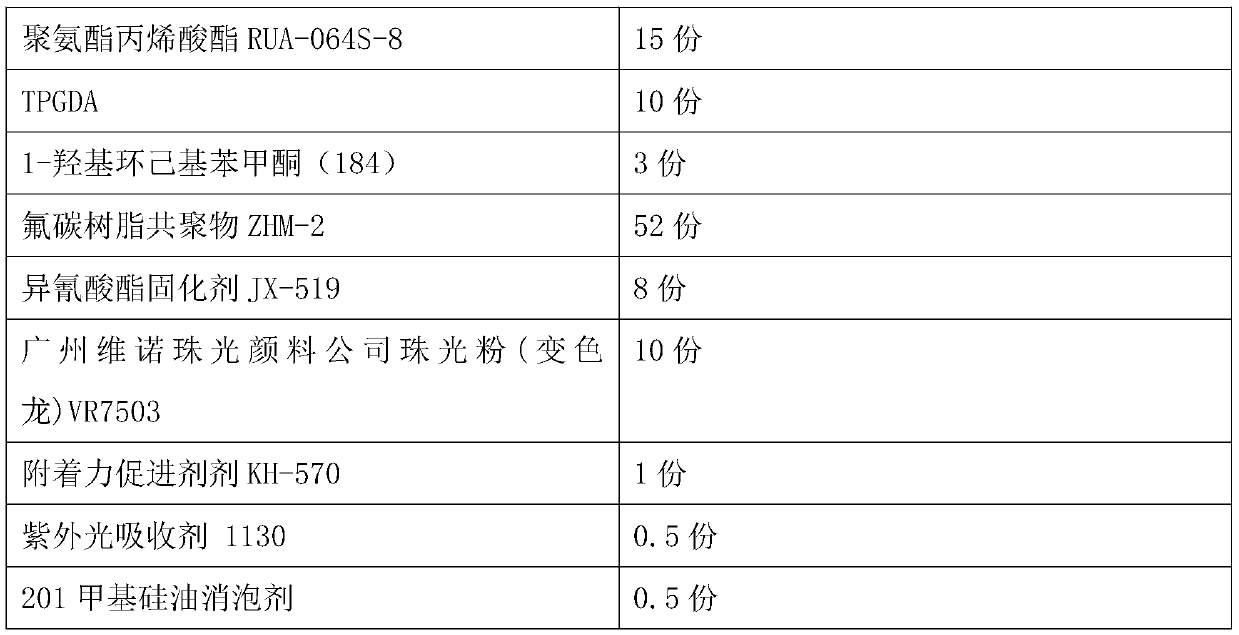

[0042] The composition and parts by weight of the scene-changing ink include 22...

Embodiment 1-1

[0045] The photosensitive polymer is EB4680 polyurethane acrylate of Allnex Resin (Shanghai) Co., Ltd., which can achieve the same effect as in Example 1.

Embodiment 1-2

[0047] The photosensitive polymer is acrylated acrylate ACAZ-251, which can achieve the same effect as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com