Synthesis and purification method of high-purity silicon tetrafluoride

A technology of high-purity silicon tetrafluoride and purification method, which is applied in the field of synthesis and purification of high-purity silicon tetrafluoride, can solve the problems of low reaction selectivity, many by-products, and no further inhibition of polymerization, and achieves improved conversion. efficiency and selectivity, increasing the effectiveness of complex rectification process systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

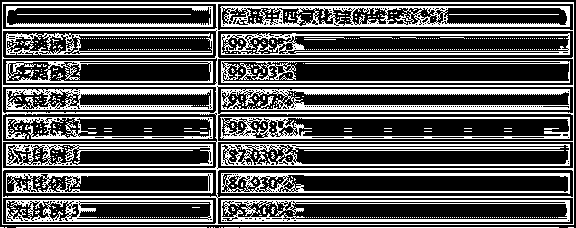

Examples

Embodiment 1

[0049] The present embodiment proposes a kind of synthetic and purification method of high-purity silicon tetrafluoride, and it comprises the following steps:

[0050] Step S1: 1000 kg of sodium fluorosilicate is pretreated; specifically, the sodium fluorosilicate is evacuated and heat-treated at 150° C. at the same time.

[0051] Step S2: The above-mentioned sodium fluorosilicate is subjected to cracking reaction in a reactor with a volume of 1000 L to prepare silicon tetrafluoride crude material; the specific cracking reaction conditions are: pressure 0.06MPa, temperature 400°C, reactor product outlet operation Flow control is 25 kg / h.

[0052] Step S3: removing trace moisture and acid gas in the first adsorption section;

[0053] Step S4: remove and inhibit polymerization of fluorosilicone in the second adsorption section; wherein, the removal and inhibition of fluorosilicone in the second adsorption section uses fluorinated resin, and the fluorinated resin is made of silv...

Embodiment 2

[0057] The present embodiment proposes a kind of synthetic and purification method of high-purity silicon tetrafluoride, and it comprises the following steps:

[0058] Step S1: 800 kg of barium fluorosilicate is pretreated; specifically, the barium fluorosilicate is evacuated and heat-treated at 100° C. at the same time.

[0059] Step S2: The above-mentioned barium fluorosilicate is subjected to cracking reaction in a reactor with a volume of 800L to prepare silicon tetrafluoride crude material; the specific cracking reaction conditions are: pressure 0.1MPa, temperature 300°C, reactor product outlet operating flow rate 20 kg / h, the reactor volume is 800 L.

[0060] Step S3: removing trace moisture and acid gas in the first adsorption section;

[0061] Step S4: remove and inhibit polymerization of fluorosilicone ether in the second adsorption section; wherein, fluorinated resin is used for removal and inhibition of fluorosilicone ether in the second adsorption section, and the...

Embodiment 3

[0065] The present embodiment proposes a kind of synthetic and purification method of high-purity silicon tetrafluoride, and it comprises the following steps:

[0066] Step S1: 400 kg of potassium fluorosilicate is pretreated; specifically, the potassium fluorosilicate is evacuated and heat-treated at 200° C. at the same time.

[0067]Step S2: The above-mentioned potassium fluorosilicate is subjected to cracking reaction in a reactor with a volume of 500 L to prepare silicon tetrafluoride crude material; the specific cracking reaction conditions are: pressure 0.02MPa, temperature 500°C, reactor product outlet operation Flow rate: 10kg / h, reactor volume: 500 L.

[0068] Step S3: removing trace moisture and acid gas in the first adsorption section;

[0069] Step S4: remove and inhibit polymerization of fluorosilicone ether in the second adsorption section; wherein, fluorinated resin is used for removal and inhibition of fluorosilicone ether in the second adsorption section, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com