Safety socket capable of automatic popup in short circuit

A safety socket and automatic pop-up technology, applied in circuits, parts of connecting devices, electrical components, etc., can solve problems such as fire danger, high current, and temperature rise of sockets and plugs, and achieve the effect of avoiding continuous short circuit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

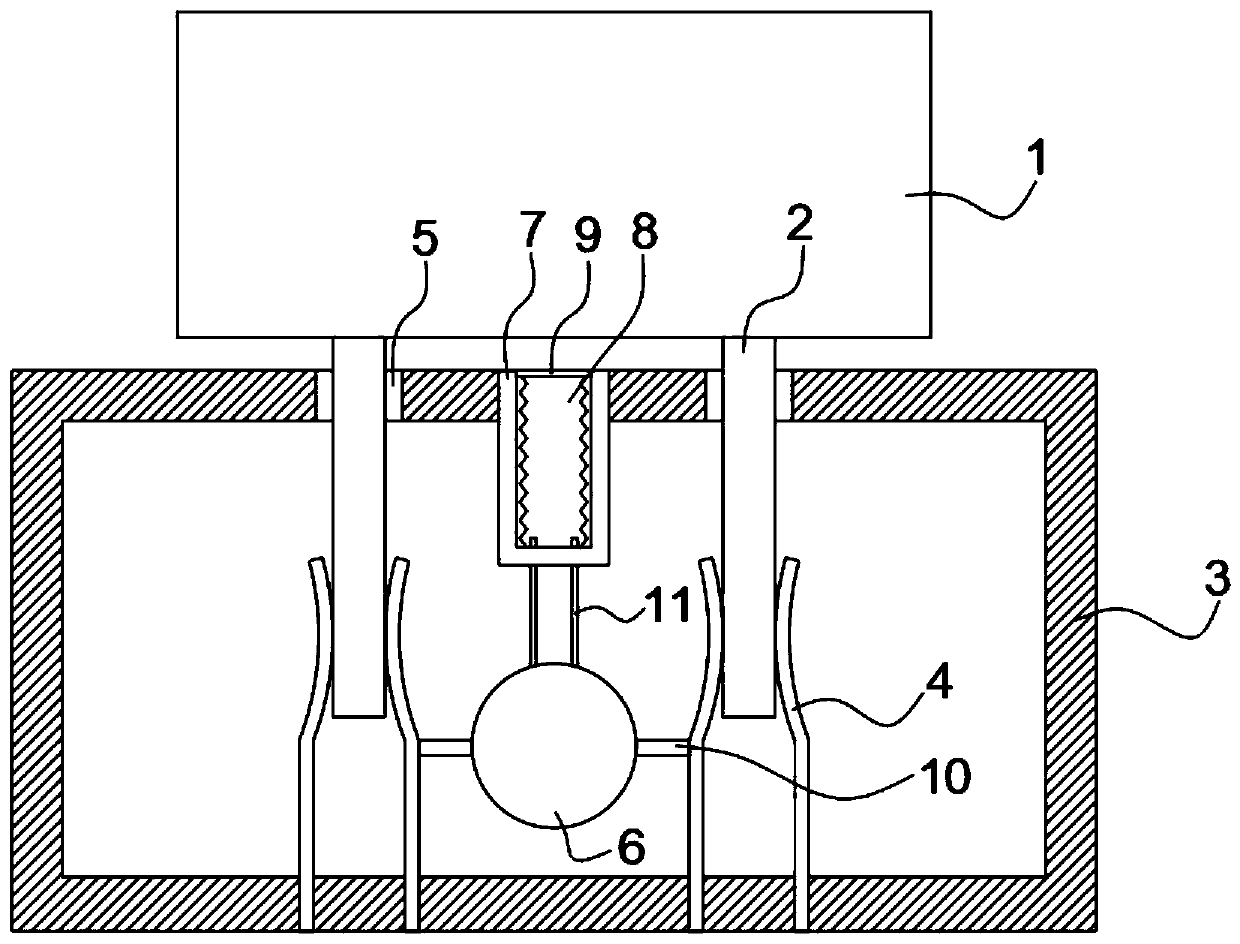

[0017] refer to Figure 1-2 , a safety socket that pops up automatically in a short circuit, including a plug and a socket. The plug includes a connector 1 and two pins 2 embedded in the end. The socket includes a square shell 3 embedded in the wall. Two groups of clamping reeds 4 are installed on the inner wall of the rear end of the body 3, the front end of the housing 3 is provided with a socket 5 at the corresponding position in the middle of each group of clamping reeds 4, and the two latches 2 can pass through the sockets respectively. 5 and clamped by a set of clamping reeds 4;

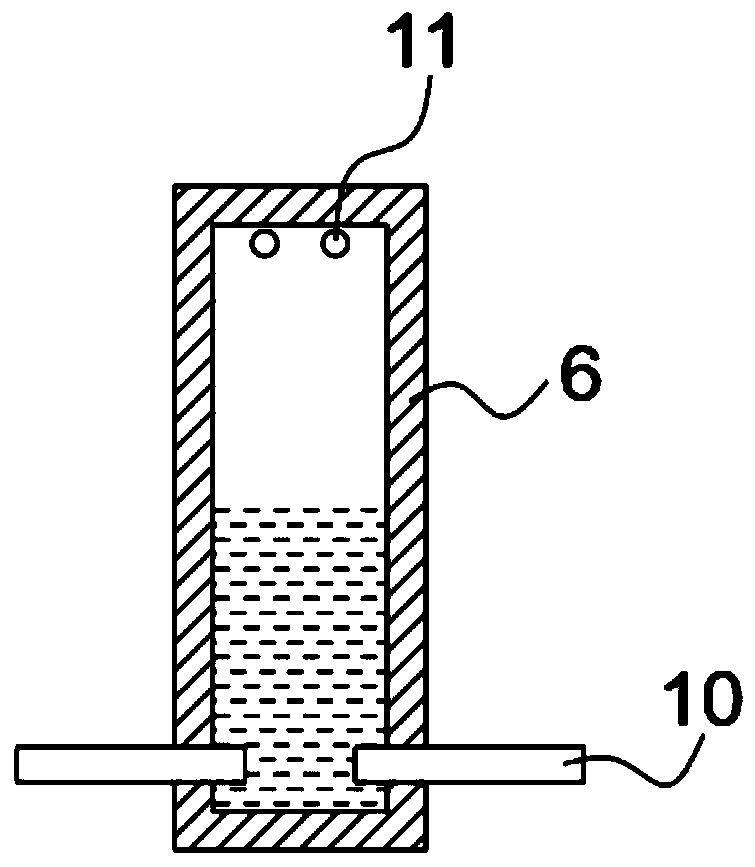

[0018] The inner bottom wall of the housing 3 is fixedly connected with a hollow cylinder 6 in the vertical direction. An evaporation chamber is arranged inside the hollow cylinder 6, and the evaporation chamber is filled with evaporating liquid. The middle part of 5 is provided with a circular opening, and the inner wall of the circular opening is fixedly connected with a storage frame 7, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com