Sound absorption and isolation composite element and transformer

A composite, sound-absorbing and insulating technology, applied in transformer/inductor noise damping, sound-generating equipment, instruments, etc., can solve problems such as mismatching noise characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

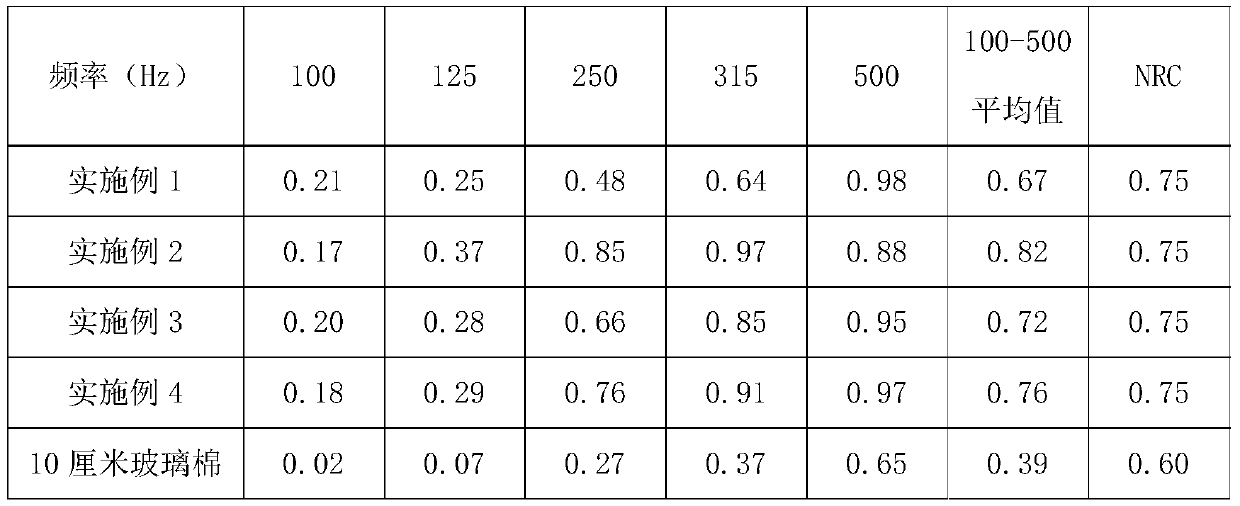

Embodiment 1

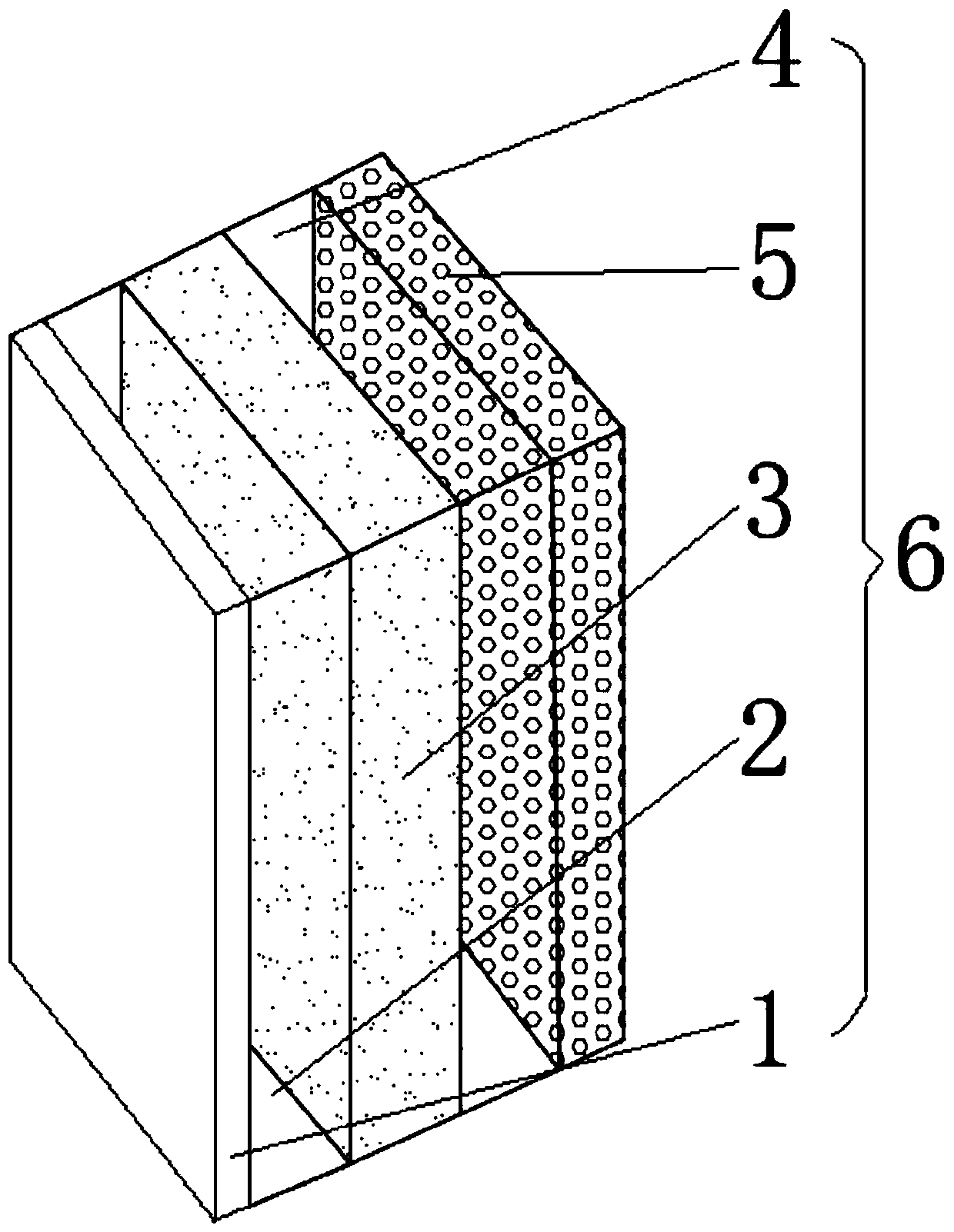

[0033] The present invention provides a transformer, which includes a transformer body and such as figure 1 The sound-absorbing and insulating composite 6 is shown, and the sound-absorbing and insulating composite 6 is arranged outside the transformer main body. Specifically, an angle iron is welded on the outer side of the outer wall of the transformer main body, and the sound-absorbing and insulating composite part 6 is fixed on the angle iron. Wherein the sound-absorbing and insulating compound 6 includes such as figure 2 As shown in the sound insulation 1 and the impedance composite sound-absorbing assembly, the impedance composite sound-absorbing assembly is arranged near the outside of the transformer main body. Specifically, the sound insulation piece 1 and the impedance compound sound absorption component can be connected by using square steel.

[0034] Wherein it can be set that: the sound insulation member 1 is a metal sound insulation board such as a steel plate ...

Embodiment 2

[0042] This embodiment provides a transformer, which includes a transformer body and such as figure 1 The sound-absorbing and insulating composite 6 shown is arranged on the outside of the transformer main body, wherein the structure of the sound-absorbing and insulating composite 6 is the same as that of the sound-absorbing and insulating composite 6 provided in Embodiment 1, However, the material and size of the sound-absorbing and insulating composite 6 are different from those of the sound-absorbing and insulating composite 6 in Embodiment 1.

[0043] In this embodiment, the sound insulation member 1 is a steel plate with a thickness of 1 mm; the micro-perforated plate 5 is a steel micro-perforated plate 5 with a thickness of 0.8 mm, a hole diameter of 1 mm, and a hole spacing of 5 mm; the fiber material layer is Polyester fiber layer, the surface density of polyester fiber layer is 2000g / m 2 And the thickness is 5 cm; the thickness of the first cavity 2 is 10 cm, and the...

Embodiment 3

[0045] This embodiment provides a transformer, which includes a transformer body and such as figure 1 The sound-absorbing and insulating composite 6 shown is arranged on the outside of the transformer main body, wherein the structure of the sound-absorbing and insulating composite 6 is the same as that of the sound-absorbing and insulating composite 6 provided in Embodiment 1, However, the material and size of the sound-absorbing and insulating composite 6 are different from those of the sound-absorbing and insulating composite 6 in Embodiment 1.

[0046] In this embodiment, the sound insulation member 1 is an aluminum plate with a thickness of 1 mm; the micro-perforated plate 5 is an aluminum micro-perforated plate 5 with a thickness of 0.5 mm, a hole diameter of 1 mm, and a hole spacing of 15 mm; the fiber material layer is Polyester fiber layer, surface density of glass wool layer is 500g / m 2 And the thickness is 5 cm; the thickness of the first cavity 2 is 5 cm, and the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Hole spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com