LED display unit board

A display unit, LED lamp bead technology, applied in static indicators, instruments, etc., can solve the problems of PCB cost increase, cost increase, device failure rate increase, etc., to facilitate PCB layout, reduce failure rate and coupling phenomenon, and reduce power consumption. The effect of consumption and heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

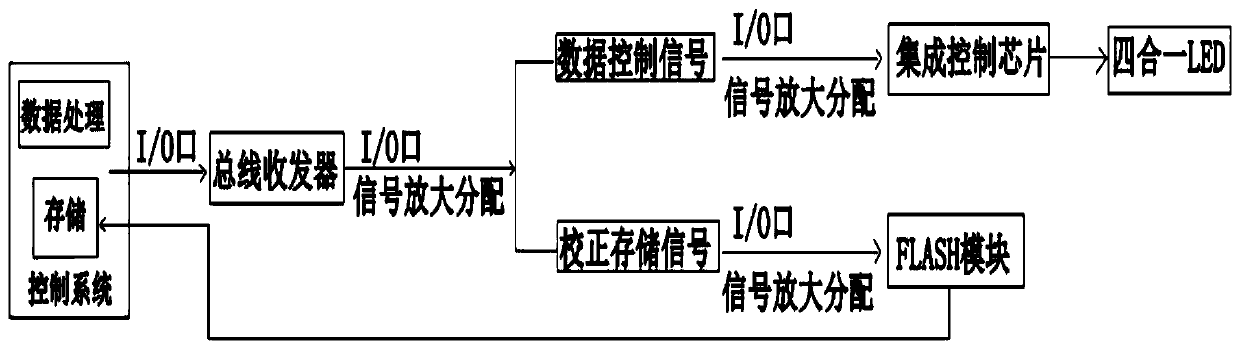

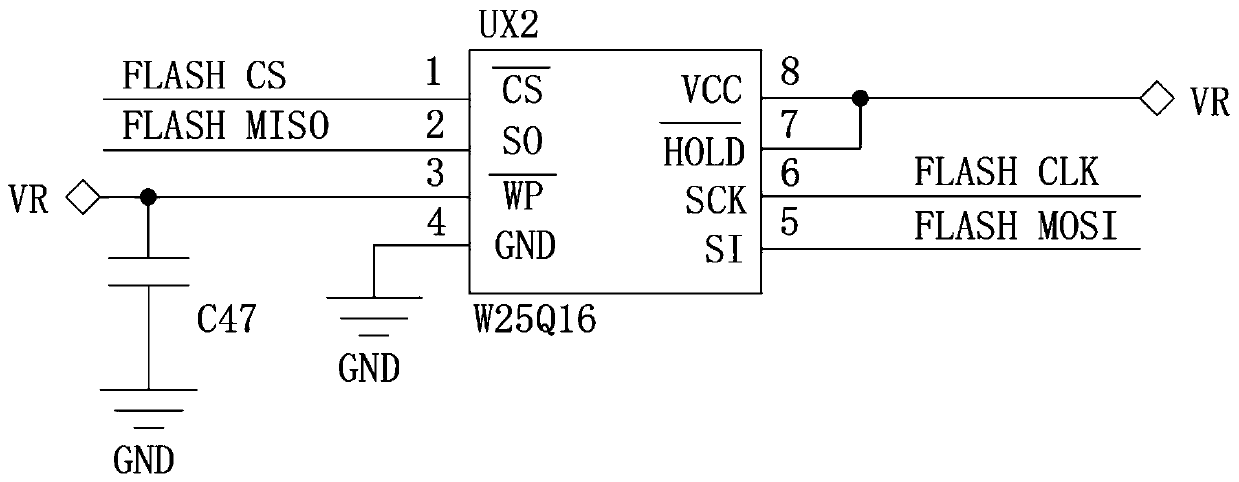

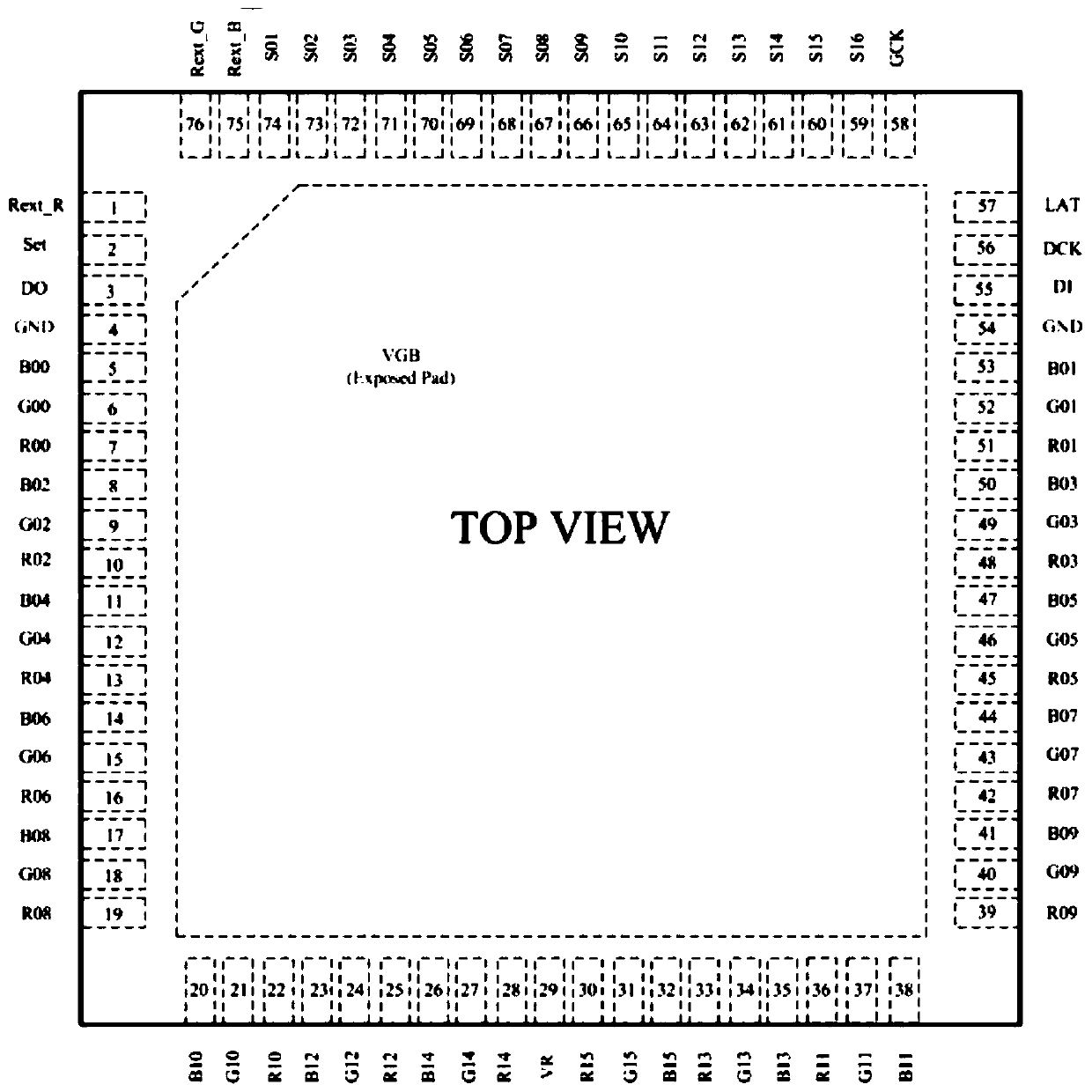

[0054] This embodiment discloses an LED display unit board, comprising: an HDI PCB board, a plurality of mini 4-in-1 full-color LED lamp beads surface-attached on the lamp surface of the HDI PCB board, and a plurality of row-column-in-one integrated chips.

[0055] The use of four-in-one surface-mounted lamp beads can solve the problem of small spacing and easy bumping without increasing production costs.

[0056] In detail, the multiple rank-in-one integrated chips described here are connected in series for communication. Before that, it should be explained that the HDI PCB in this embodiment is integrated with numerous circuits, and the circuits here are used to realize the connection of various components assembled on the HDI PCB.

[0057] The multiple row-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com