Automatic simulation experiment system

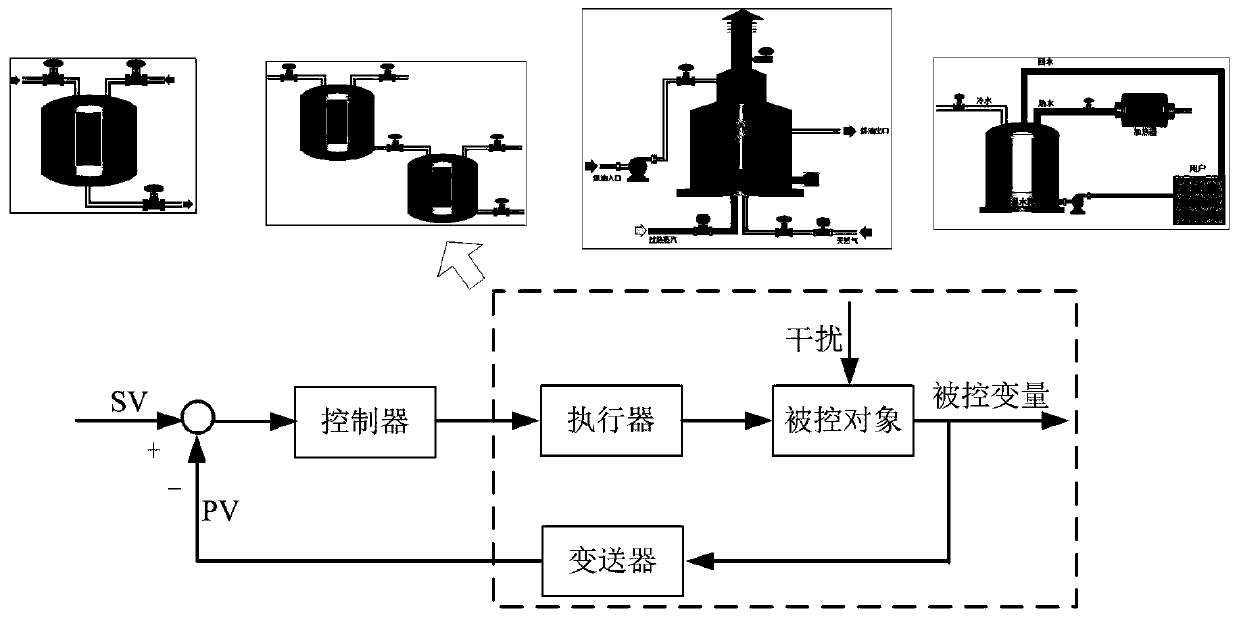

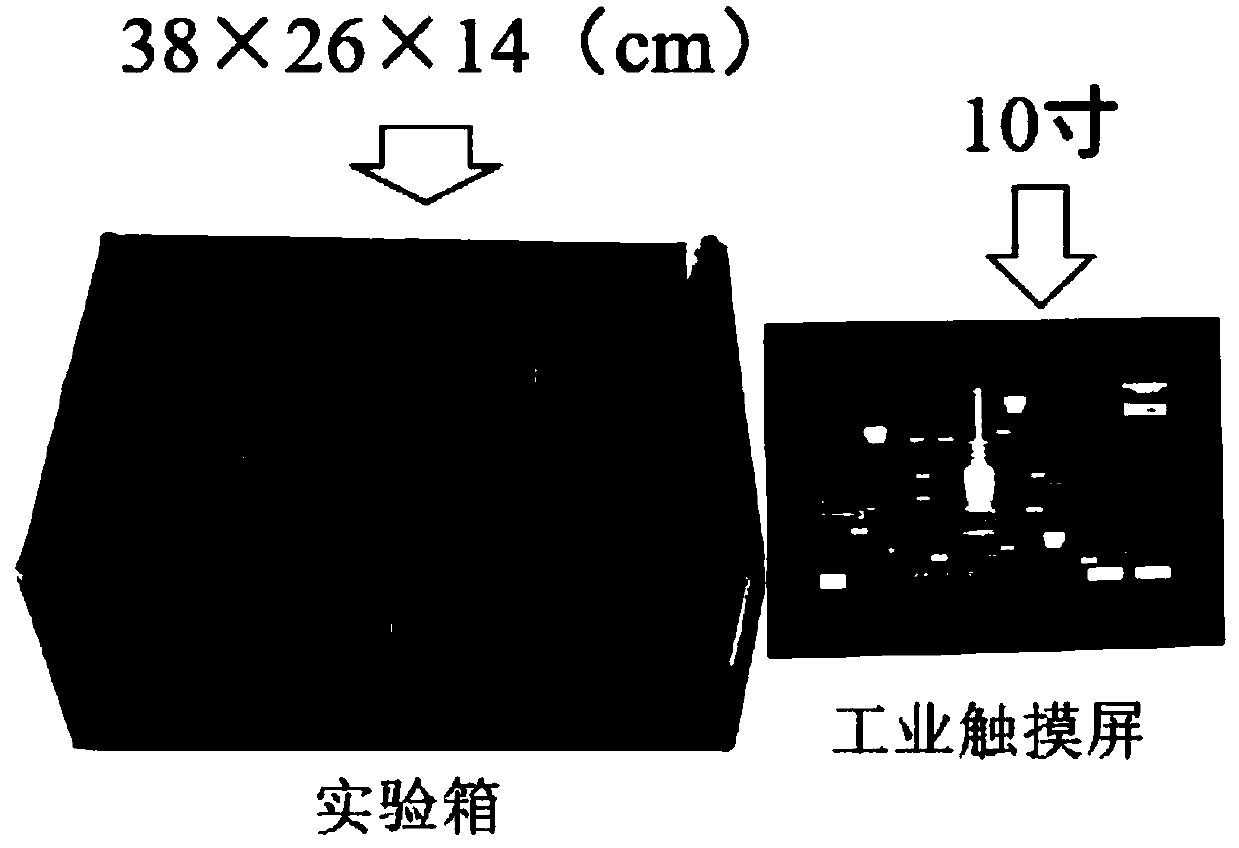

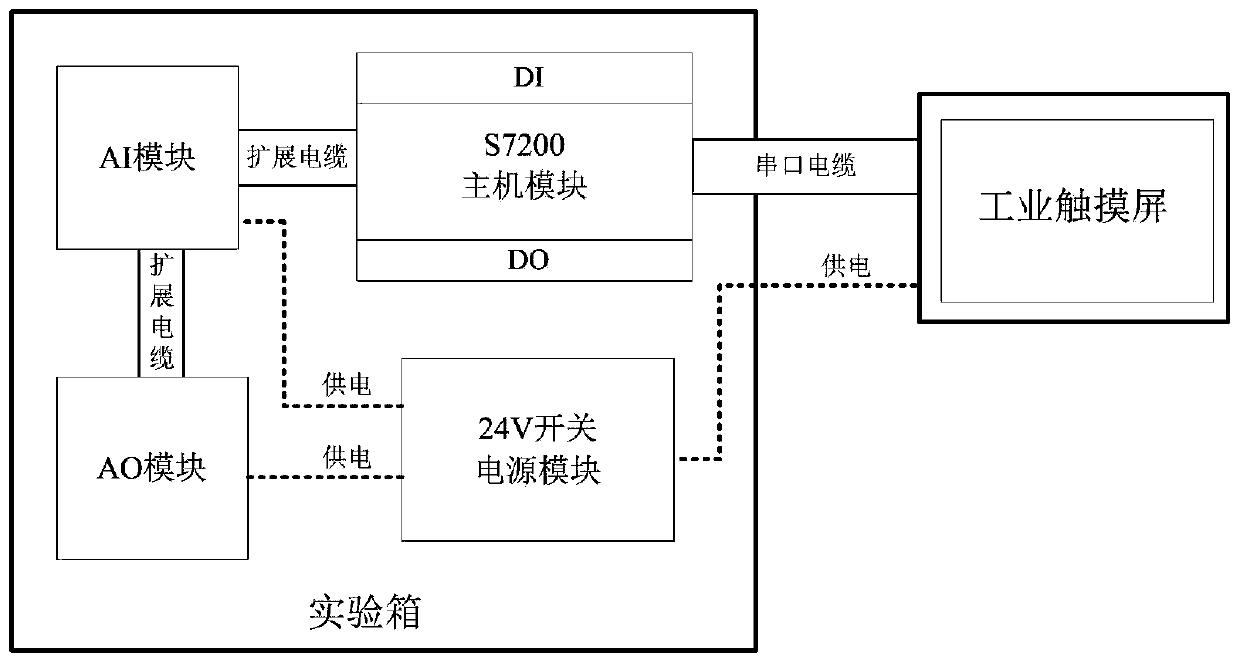

A technology of simulation experiment and experiment box, which is applied in the direction of instruments, simulators, space navigation equipment, etc., can solve the problems of difficult training of students' hands-on ability, heavy maintenance, and inability to move, so as to facilitate the test control effect and exercise hands-on operation capacity, saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Figure 7 The heating furnace simulation system shown not only gives the temperature change of the heating furnace material outlet according to the energy balance, but also simulates the combustion of fuel, furnace radiation and convective heat release, and the flow of flue gas, which can reflect the negative pressure of the furnace, Changes in furnace temperature and flue gas outlet oxygen content. When building a control system, it is necessary to complete the start-up process in strict accordance with the steps, otherwise accidents such as explosion and coking will occur. Changes also need to pay attention to the impact of the combustion system to avoid accidents such as black smoke and flameout, and ensure the energy-saving, environmentally friendly and efficient operation of the furnace. The simulation system will give warnings for various faults and force the shutdown.

[0033] The control of the heating furnace needs to be put into operation in strict accordance ...

Embodiment 2

[0035] Figure 8The hot water supply system shown is based on the actual hotel hot water supply as the engineering background, which is convenient for students to understand the process and control requirements. Before the control, it is first necessary to calculate the size of the thermal insulation water tank, the power of the heater and the adjustment according to the number of rooms and users. The flow coefficient of the valve, and then design and implement the control system according to the high and low peak water conditions, to ensure the uninterrupted and stable hot water supply 24 hours a day.

[0036] The control of the hot water supply system requires a strict start-up process. In the design of the control scheme, it is not only to complete the coupled control of temperature and liquid level, but also to complete the operations of replenishing water, returning water, and switching according to the peak and low peak conditions of water consumption. The control effect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com