Device and method for detecting impurities and defects of toughened glass curtain wall on spot

A tempered glass, on-site detection technology, applied in measurement devices, optical testing of flaws/defects, material analysis by optical means, etc. High degree of integration, accurate size and accurate position information, and convenient detection of impurities and defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The invention provides a device for on-site detection of impurities and defects of a tempered glass curtain wall, which includes a polarized light source 1 , a detection host 2 and a connecting wire 3 .

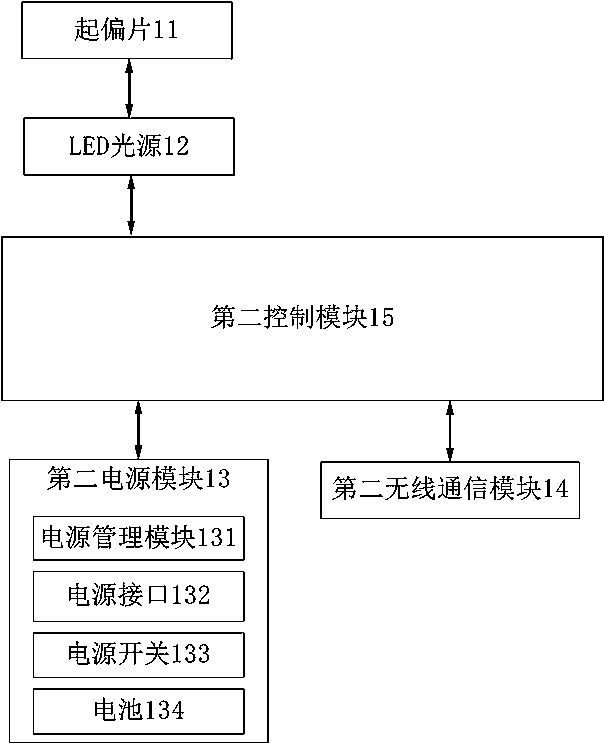

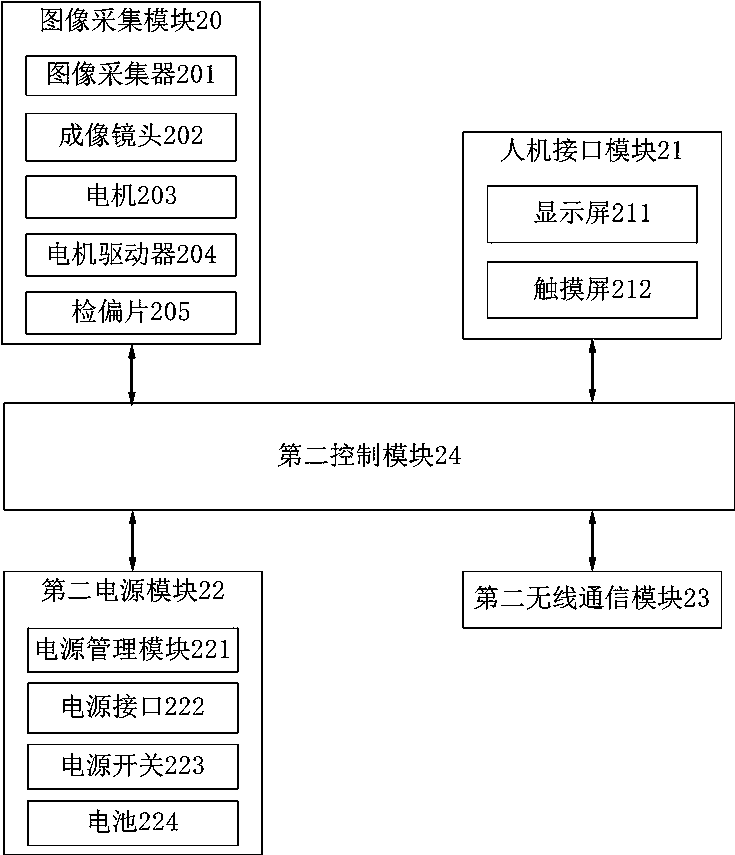

[0063] figure 1 A structural block diagram of the polarized light source 1 in Embodiment 1 of the device for on-site detection of impurities and defects in tempered glass curtain walls provided by the present invention, figure 2 The structural block diagram of the detection host 2 of the first embodiment of the device for on-site detection of impurities and defects in tempered glass curtain walls provided by the present invention. For the sake of simplicity, only the components related to the subject of the text are shown, the overall polarized light source 1 and the detection host 2 Many other configurations are possible and many other types of equipment can be used. Such as figure 1 As shown, the polarized light source 1 of the device for on-site detection of impu...

Embodiment 2

[0099] The invention provides a device for on-site detection of impurities and defects of a tempered glass curtain wall, which includes a polarized light source 1 , a detection host 2 and a connecting wire 3 . The polarized light source 1 of the device for on-site detection of impurities and defects of a tempered glass curtain wall is the same as that of Embodiment 1, and will not be repeated here.

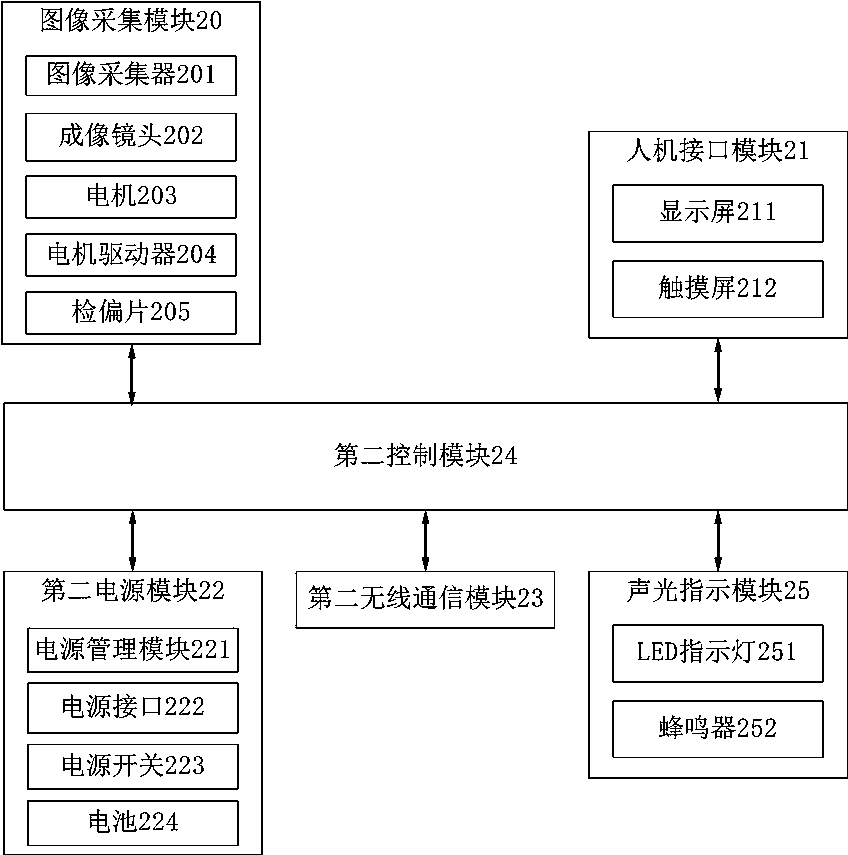

[0100] The detection host 2 of the device for on-site detection of impurities and defects of the tempered glass curtain wall adopts an integrated structure. On the basis of Embodiment 1, it may also include: an acousto-optic indicating module 25, and the structural block diagram of the detection host 2 is as follows: image 3 shown.

[0101] The acousto-optic indication module 25 is electrically connected to the second control module 24 bidirectionally, and includes an LED indicator light 251 and a buzzer 252 for receiving the acousto-optic indication signal sent by the second con...

Embodiment 3

[0104] The invention provides a device for on-site detection of impurities and defects of a tempered glass curtain wall, which includes a polarized light source 1 , a detection host 2 and a connecting wire 3 . The polarized light source 1 of the device for on-site detection of impurities and defects of a tempered glass curtain wall is the same as that of Embodiment 1, and will not be repeated here.

[0105] The detection host 2 of the device for on-site detection of impurities and defects of the tempered glass curtain wall adopts an integrated structure, and on the basis of the third embodiment, it may also include: a data interface 26, and the structural block diagram of the detection host 2 is as follows Figure 4 shown.

[0106] The data interfaces 26 are bidirectionally electrically connected to the second control module 24 and are fixedly installed on the second housing 004 .

[0107] The data interface 26 is used for the second control module 24 to input and output data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com