Method for rapidly detecting storage quality of aseptically packaged sea cucumber protein peptide powder based on DVS and GC-IMS technologies

A GC-IMS and sea cucumber protein technology, which is applied in the field of flavor chemical analysis, can solve problems such as easy denaturation, deterioration, nutrient loss, and polypeptide texture changes, achieving high accuracy and reliability, saving raw materials, and rapid identification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

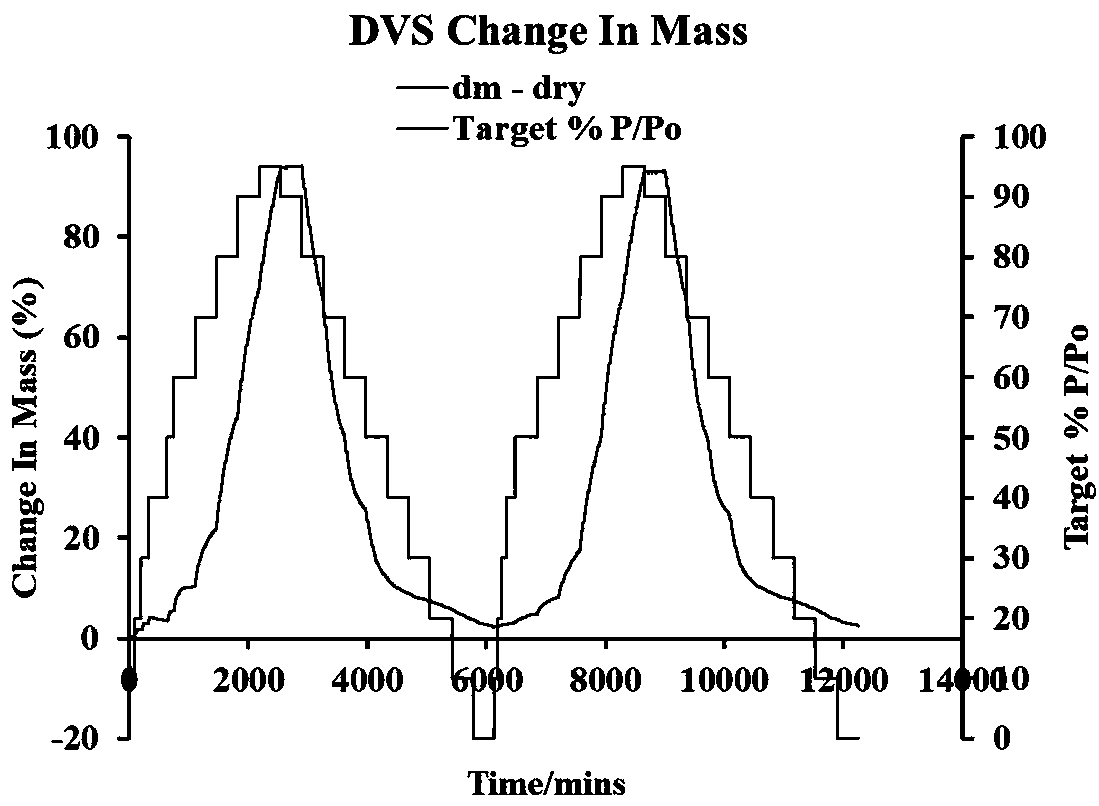

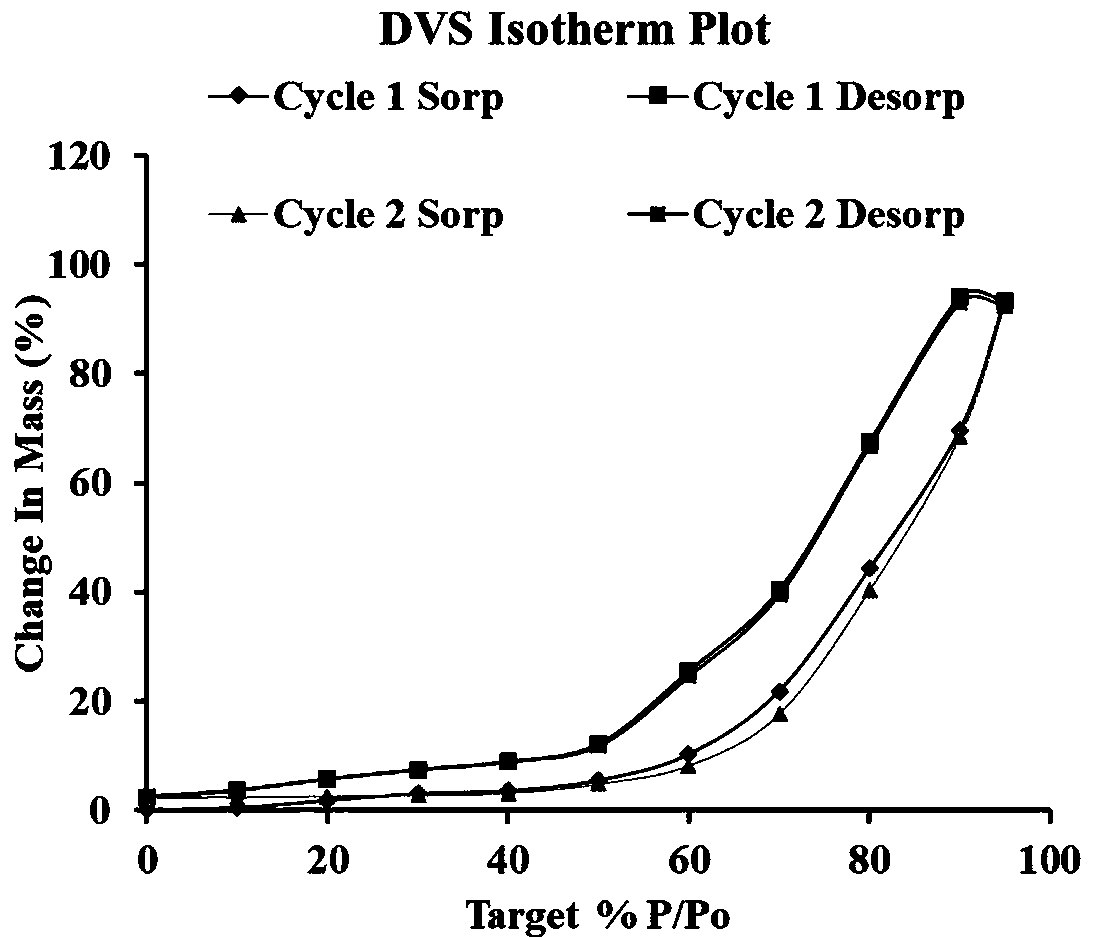

[0025] Weigh a group of 0.022g sea cucumber protein peptide powder, put it on the sample plate of the dynamic moisture adsorption instrument, and pass a constant flow of high-purity nitrogen gas into the dynamic moisture adsorption instrument to balance the experimental temperature to 25°C and the relative humidity to 2%RH ;Data such as sample quality and relative humidity are automatically recorded every 55s. When the sample quality change rate is less than 0.0015% / min for two consecutive times, or the equilibrium time exceeds 350min, the sample is considered to have reached moisture absorption equilibrium, and then forced to increase to the next level Relative humidity: 0RH-90%RH in the sample chamber changes with a 10% humidity gradient, 90%RH-95%RH changes with a 5% gradient, 0%RH rises to the maximum value of 95%RH and then drops to the minimum value of 0%RH , complete two cycles to obtain the moisture absorption kinetic curve of sea cucumber protein peptide powderfigure 1...

Embodiment 2

[0027] Weigh a group of 0.025g sea cucumber protein peptide powder, put it on the sample plate of the dynamic moisture adsorption instrument, and pass a constant flow of high-purity nitrogen gas into the dynamic moisture adsorption instrument to balance the experimental temperature to 25°C and relative humidity to 5%RH ;Data such as sample quality and relative humidity are automatically recorded every 52s. When the sample quality change rate is less than 0.003% / min for two consecutive times, or the equilibrium time exceeds 355min, the sample is considered to have reached moisture absorption equilibrium, and then forced to increase to the next level Relative humidity: 0RH-90%RH in the sample chamber changes with a 10% humidity gradient, 90%RH-95%RH changes with a 5% gradient, 0%RH rises to the maximum value of 95%RH and then drops to the minimum value of 0%RH , complete two cycles to obtain the moisture absorption kinetic curve of sea cucumber protein peptide powder figure 1 an...

Embodiment 3

[0029] Weigh a group of 0.026g sea cucumber protein peptide powder, put it on the sample tray of the dynamic moisture adsorption instrument, and pass a constant flow of high-purity nitrogen into the dynamic moisture adsorption instrument to balance the experimental temperature to 25°C and relative humidity to 0%RH ;Data such as sample quality and relative humidity are automatically recorded every 58s. When the sample quality change rate is less than 0.0025% / min for two consecutive times, or the equilibrium time exceeds 350min, the sample is considered to have reached moisture absorption equilibrium, and then forced to increase to the next level Relative humidity: 0RH-90%RH in the sample chamber changes with a 10% humidity gradient, 90%RH~95%RH changes with a 5% gradient, 0%RH rises to the maximum value of 95%RH and then drops to the minimum value of 0%RH , complete two cycles to obtain the moisture absorption kinetic curve of sea cucumber protein peptide powder figure 1 and mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com