Simulation device of composite engine supersonic/subsonic combustion heat environment

A simulation device, subsonic technology, used in jet engine testing, gas turbine engine testing, etc., can solve verification limitations, difficulties and other problems, achieve effective thermal protection, uniform mixing, and improve combustion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

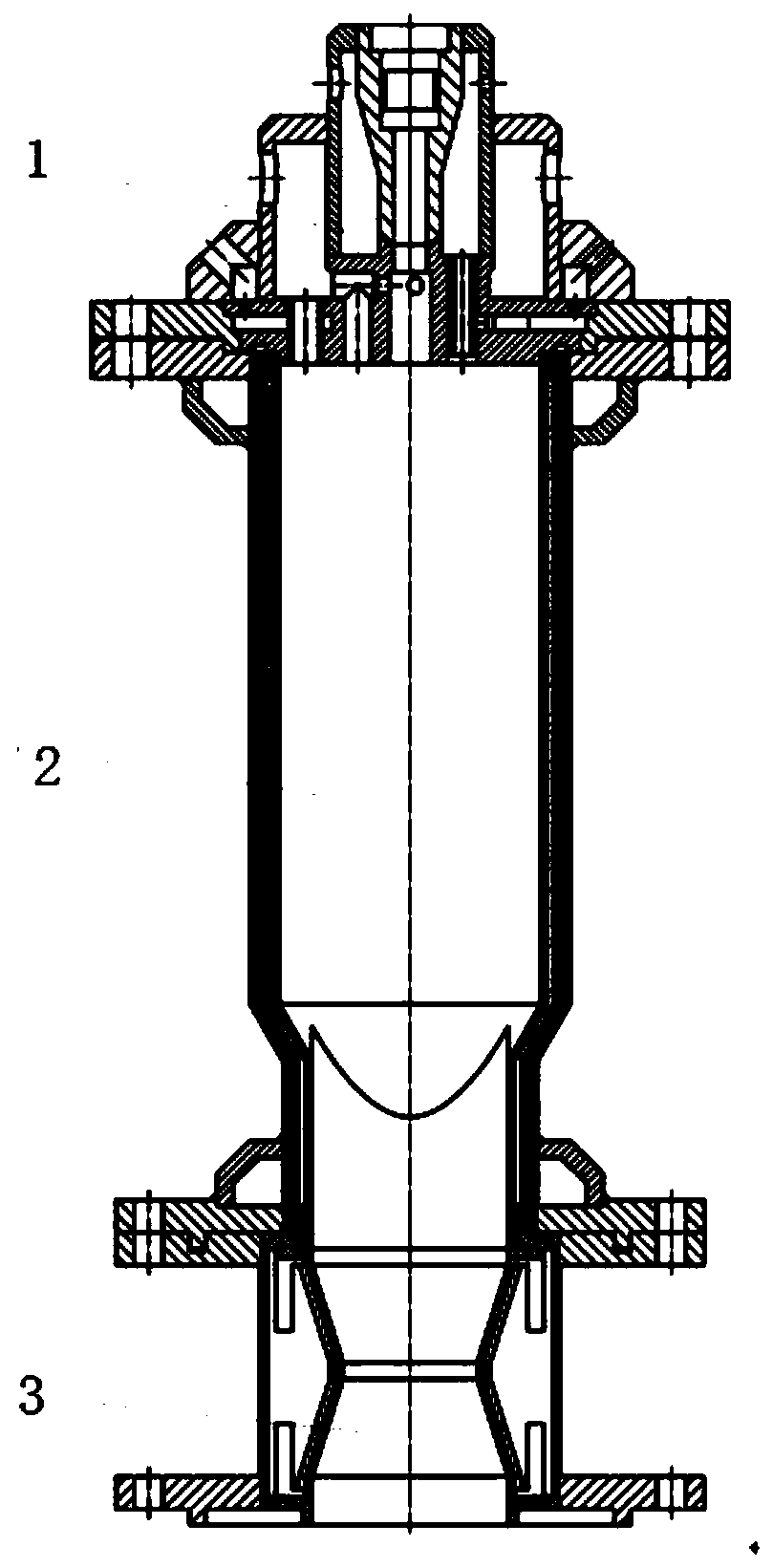

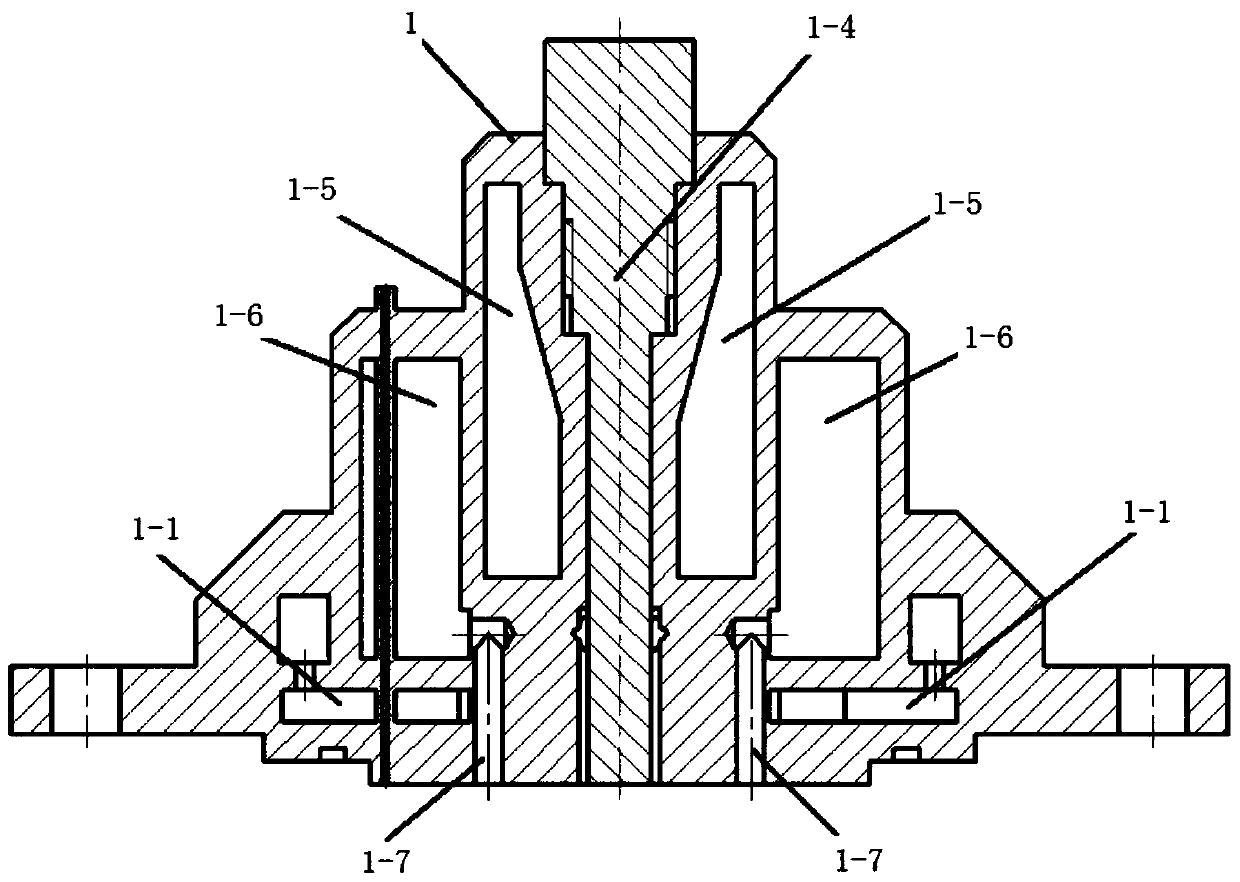

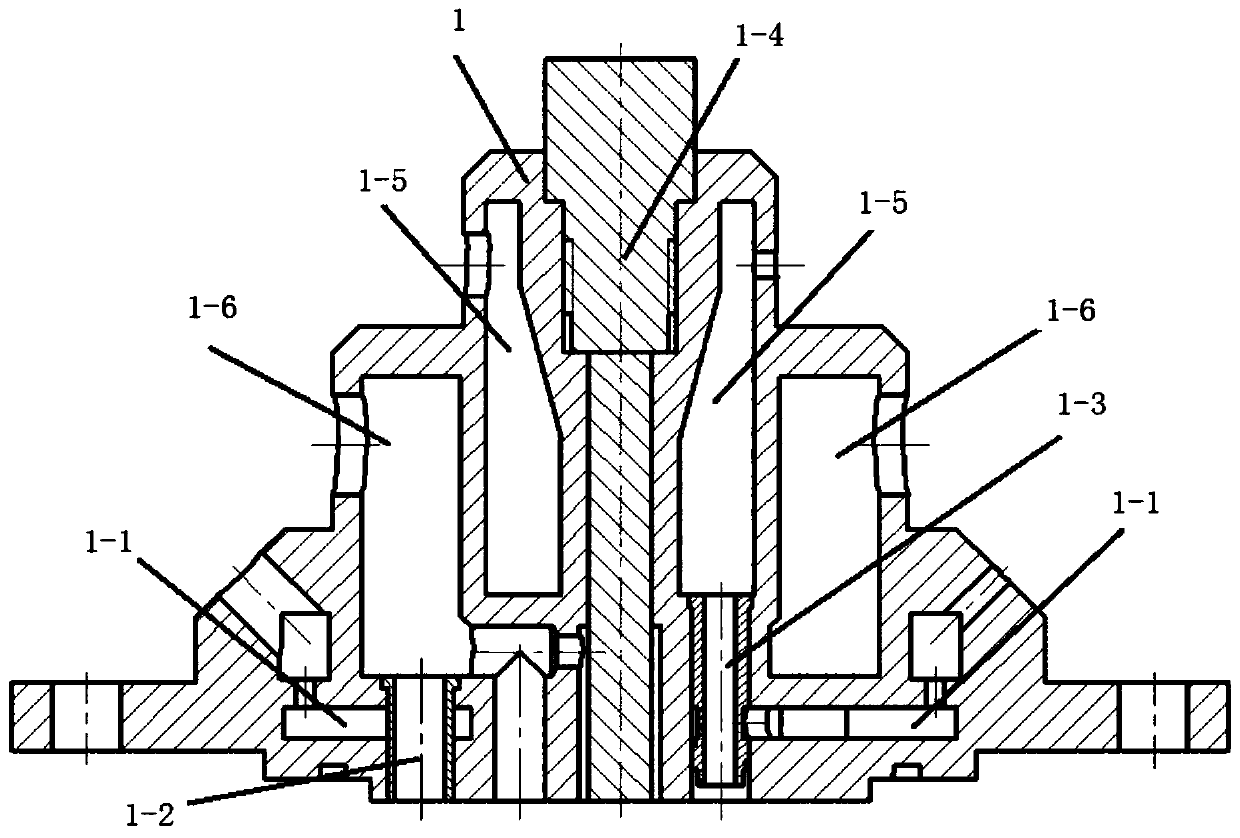

[0033] The present invention is a combination engine super / subsonic combustion thermal environment simulation device, such as figure 1 As shown, the injector 1 and the combustion chamber 2 are connected up and down; the body of the combustion chamber 2 adopts a welded structure of the inner liner and the shell, and a cooling channel is formed between the two. The cooling water inlet is located at the lower part of the combustion chamber, and the cooling water The outlet is positioned at the head position on the top, and the body of the combustion chamber 2 is cylindrical. Along the central axis of the injector 1, there is a central cavity with upper and lower openings, which communicates with the combustion chamber 2. An electric spark igniter 1-4 is arranged axially in the central cavity; the inner diameter of the central cavity is slightly larger than that of the electric spark ignition The diameter of the cylindrical rods of devices 1-4 is such that there is a gap between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com