Intelligent production detection and traceability system of tractor reducer shell

A technology for production testing and testing systems, which is applied in the direction of instruments, measuring devices, image data processing, etc., can solve problems such as inability to guarantee processing quality and accuracy, waste of resources, and wrong judgments, so as to promote production efficiency and quality stability, reduce Loss, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

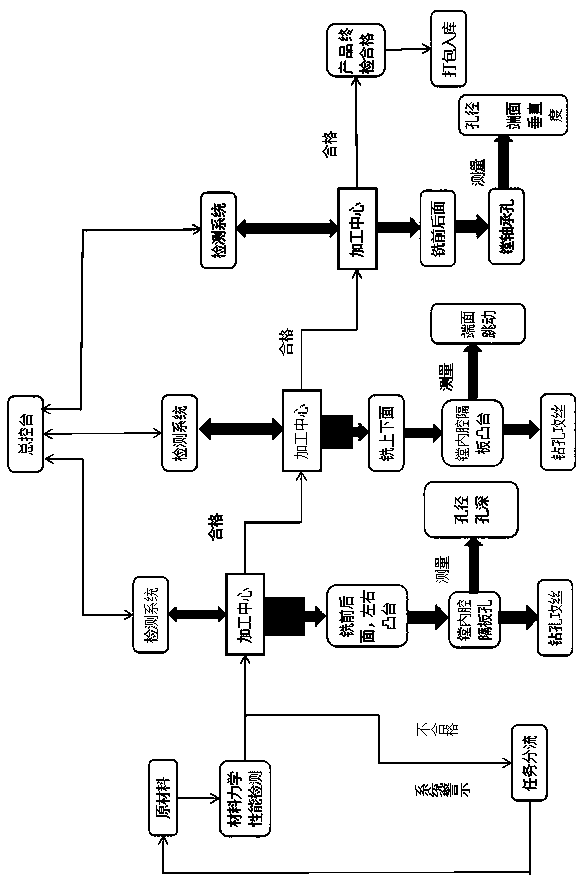

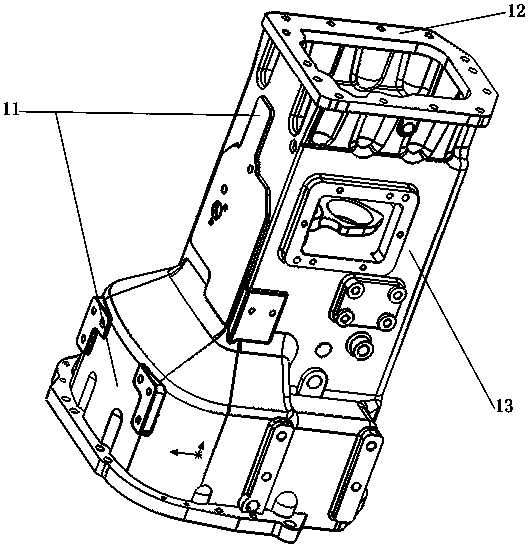

[0032] Such as Figure 3-4 , is a three-dimensional schematic diagram of the tractor reducer housing according to the present invention, in which the front end face 8, the rear end face 12, the right side face 9, the left side face 13, the upper face 11 and the bearing hole 10 are respectively pointed out in the figure, and its processing The procedures of the process are roughly divided into the following three steps, namely the three key processing procedures described in this article:

[0033] (1) Milling the bosses on the front and rear end faces and the left and right end faces, boring inner cavity partition holes, drilling and tapping, etc.;

[0034] (2) Milling the upper and lower sides of the shell, boring the boss of the inner cavity partition, drilling and tapping, etc.;

[0035] (3) Fine milling of the front end face, rear end face, boring bearing holes, etc.

[0036] The master console collects the geometric dimensions of qualified finished products through detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com