Construction method for replacement of tunnel secondary liner

A construction method and tunnel technology, which is applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of high safety risk and difficult construction of the second lining of the tunnel, so as to achieve high safety, speed up the operation cycle time, and ensure safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

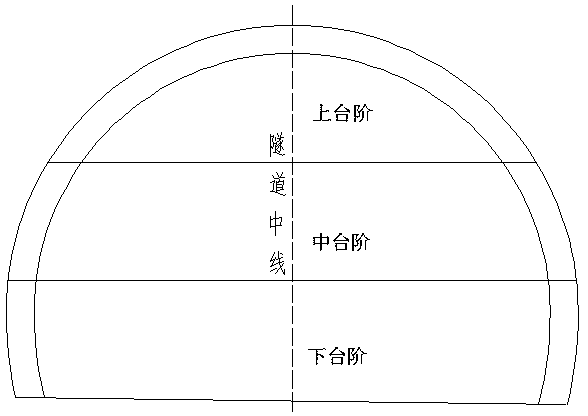

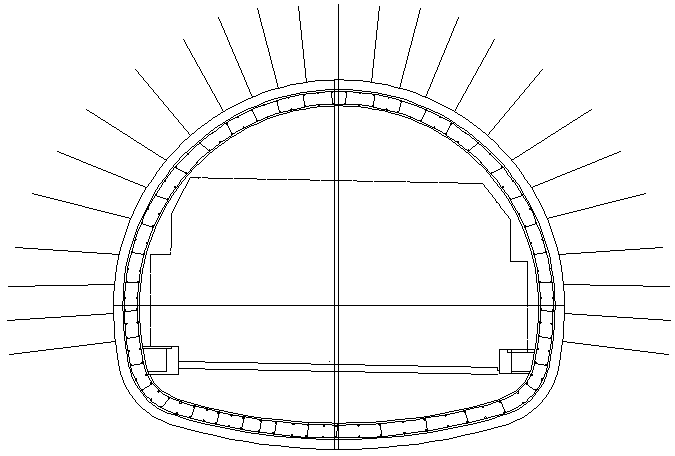

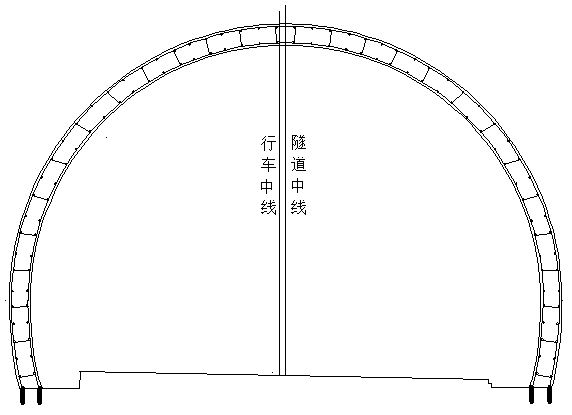

[0062] Example: construction method for the replacement of the second lining of the tunnel

[0063] The implementation site is Tianding Expressway, a part of the east-west horizontal line of the national expressway-G30 Lianhuo Expressway. The TD3 standard Qinzhou Tunnel is located in the west of Guanzi Town, Tianshui City. It is a separated 4-lane expressway tunnel with 5 emergency stops There are 6 cross-holes for pedestrians and 5 cross-holes for vehicles. The starting and ending pile numbers of the uplink line are SK162+180~166+810, the total length of the tunnel is 4630m, and the maximum buried depth is 184m. The starting and ending piles of the downlink line are XK162+250~XK166+840, the total length of the tunnel is 4590m, and the maximum buried depth is 183.7m. Set up a φ6.7m ventilation shaft 25m to the left of XK164+750. The project started construction in October 2007 and opened to traffic in June 2011. The design speed is 80 km / h, the clear width of the tunnel is 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com