Construction method for reinforced supporting structure for foundation pit ramp under heavy-load passing condition

A technology of supporting structure and construction method, which is applied in the direction of basic structure engineering, construction components on-site preparation, excavation, etc., can solve the problems of difficult removal of concrete row piles, unfavorable underground structure construction, and influence on construction progress, etc., and achieve recovery value Safe and fast, promising development and application prospects, resource-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

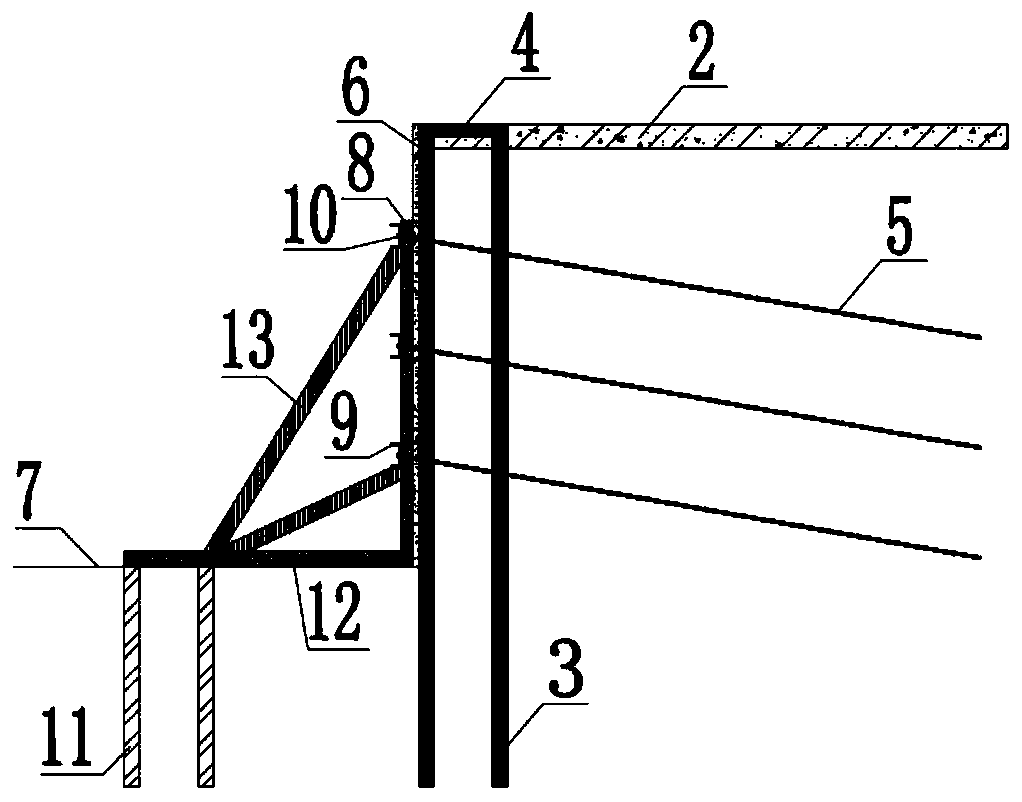

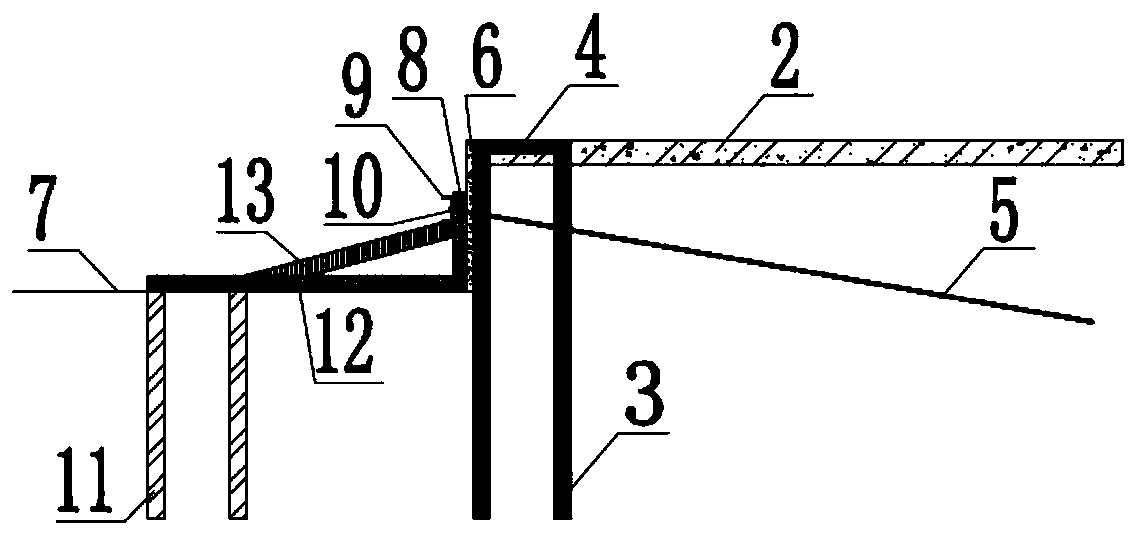

[0030] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

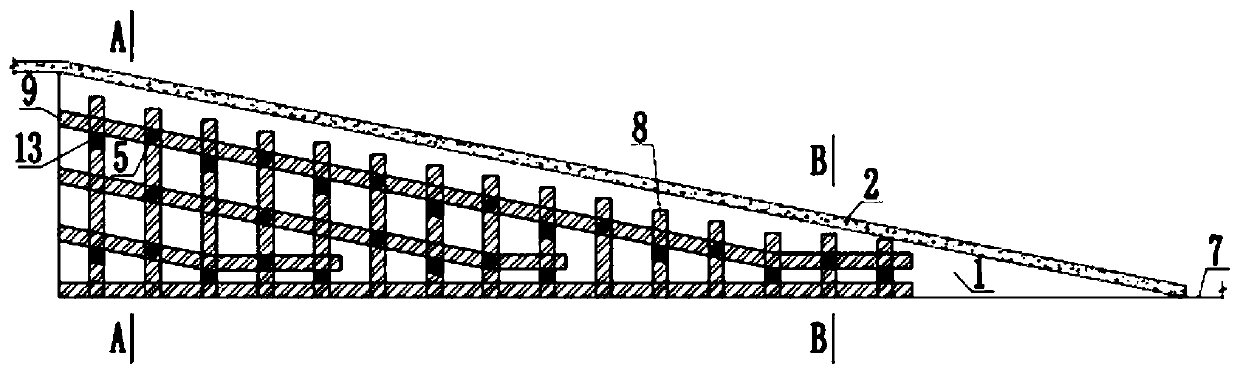

[0031] Construction molding structure of the present invention such as Figure 1 to Figure 4 As shown, it is specifically a construction method for strengthening the support structure of the foundation pit slope under heavy traffic conditions. The specific implementation should also be designed according to the requirements of the construction site. Therefore, the specific implementation includes the following steps:

[0032] A. Design of heavy-duty traffic function requirements for foundation pit ramps, including:

[0033] A1. Collect relevant information and determine the parameters such as the plane position, size, height, slope ratio and the distance between heavy-load traffic and the slope of the ramp, and the maximum load value set up for the foundation pit ramp 1;

[0034] A2. According to the heavy-duty traffic parameters,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com