A kind of in-situ self-generated micro-foam diversion acidification liquid, acidification diversion method and application

An in-situ autogenous, acidified and diverted technology, applied in chemical instruments and methods, earthwork drilling, drilling compositions, etc., can solve the problems of high construction cost of a single well, limit a large number of popularization and application, etc., to reduce construction costs, Simplify construction procedures and increase the effect of elastic driving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The indoor simulation experiment of an oilfield core is taken as an example to illustrate.

[0052] Flow experiments using carbonate cores with different permeability simulate the fluid permeability in the reservoir due to reservoir heterogeneity under formation conditions. The core is from the Longwangmiao Formation core in Anyue, Sichuan, numbered 1#. 1# core: diameter 2.36cm, porosity 30.5%, permeability 698×10 -3 μm 2 , the simulated temperature is 60°C, and the pressure is 1MPa.

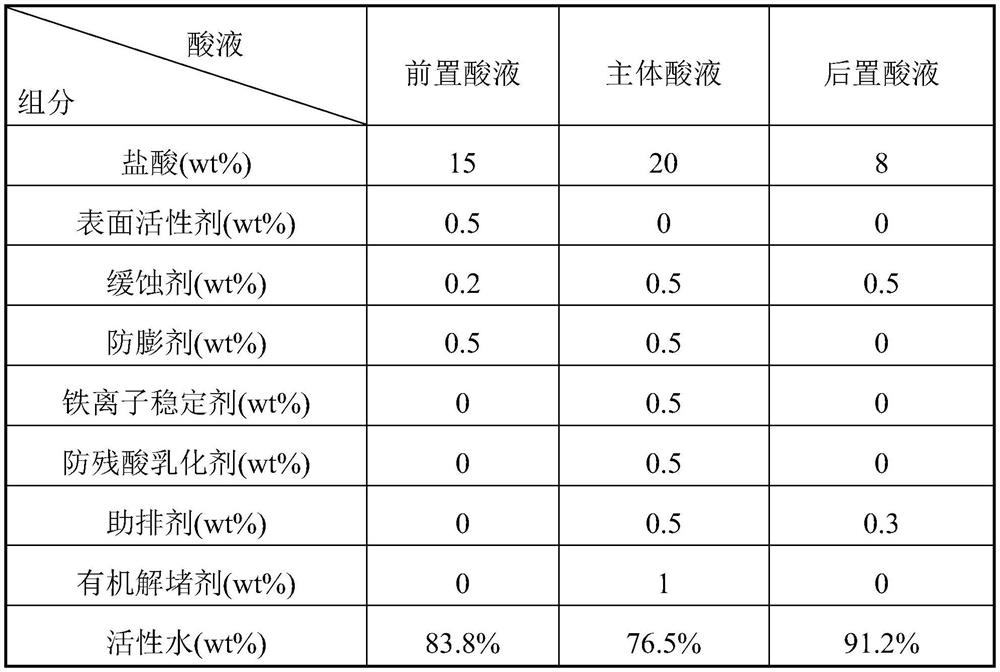

[0053] Preparation of acid solution: (1) In-situ self-generated micro-foam turning acidification solution (pre-acid solution) includes: 15% hydrochloric acid, 0.5% fatty alcohol polyoxyethylene polyoxypropylene ether, 0.2% corrosion inhibitor uropine, 0.5% anti-swelling agent ammonium chloride, the balance is active water. (2) The main acid solution includes: 20% hydrochloric acid, 0.5% corrosion inhibitor utolopine, 0.5% clay anti-swelling agent, 0.5% anti-residual acid emulsifier, 0...

Embodiment 2

[0058] The indoor simulation experiment of an oilfield core is taken as an example to illustrate.

[0059] Flow experiments using carbonate cores with different permeability simulate the fluid permeability in the reservoir due to reservoir heterogeneity under formation conditions. The core is from the Longwangmiao Formation core in Anyue, Sichuan, numbered 2#. 2# core: diameter 2.68cm, porosity 28.7%, permeability 590×10 -3 μm 2 , the simulated temperature is 60°C, and the pressure is 2MPa.

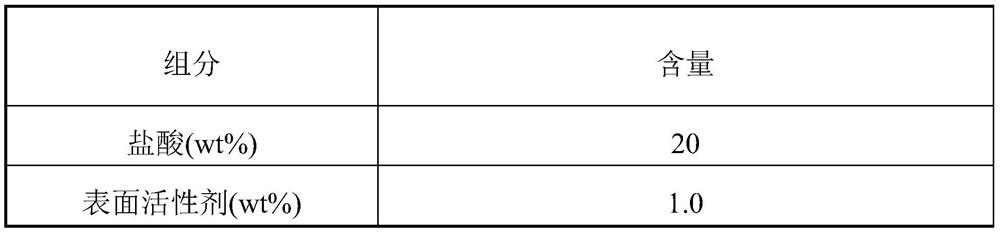

[0060] Prepare the acid solution (the turning acidification solution of self-generated microfoam in situ in the present invention), including: 18% hydrochloric acid, 0.8% polyethylene glycol perfluorobutyrate, 0.3% corrosion inhibitor tannic acid, 0.7% anti-swelling agent two Zirconium oxychloride, the balance is active water. See Table 2 for the composition of the diverting acidification solution of in-situ self-generated microfoam.

[0061] The diverting acidizing liquid of the sel...

Embodiment 3

[0065] The indoor simulation experiment of an oilfield core is taken as an example to illustrate.

[0066] Flow experiments using carbonate cores with different permeability simulate the fluid permeability in the reservoir due to reservoir heterogeneity under formation conditions. The core is from the Longwangmiao Formation in Anyue, Sichuan, numbered 3#. 3# core: diameter 2.46cm, porosity 31.4%, permeability 627×10 -3 μm 2 , the simulated temperature is 60°C, and the pressure is 2MPa.

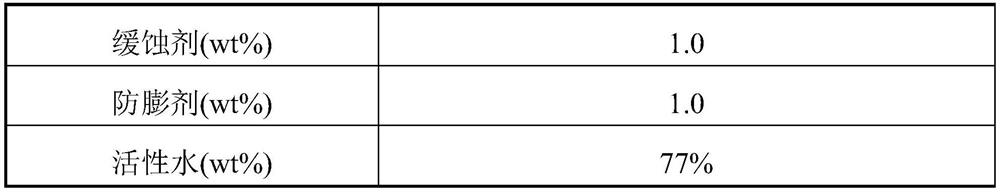

[0067] Preparation of acid solution (in-situ self-generated microfoam turning acidification solution of the present invention), including: 20% hydrochloric acid, 1.0% fatty alcohol polyoxyethylene polyoxypropylene ether, 1.0% corrosion inhibitor rhodin, 1.0% anti-swelling agent guanidine salt , and the balance is active water. Table 3 shows the composition of the diverting acidification solution for the in-situ self-generated microfoam.

[0068] The diverting acidizing liquid of the self-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com