Wave-transmitting composite material half cover and preparation method thereof

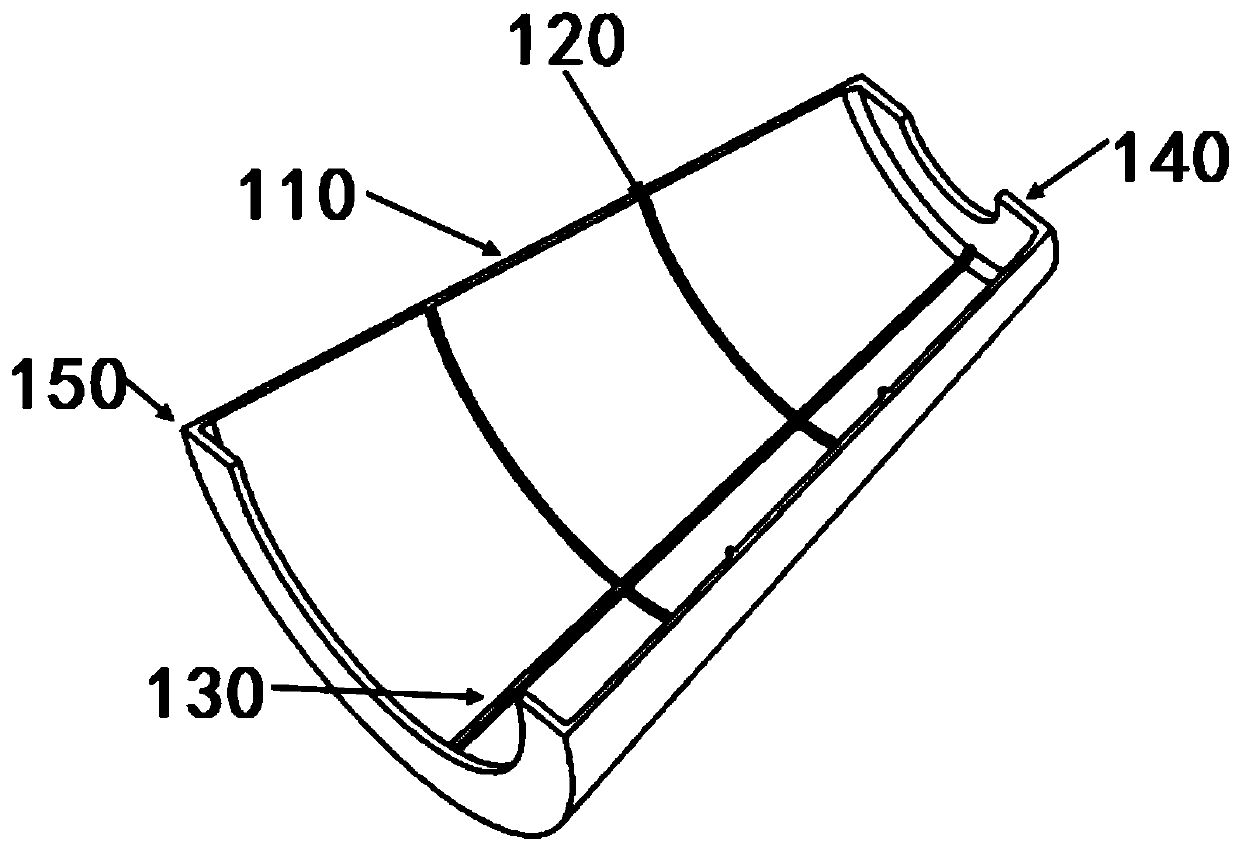

A technology of composite materials and resin composite materials, which is applied in the field of wave-transparent composite material half-covers and its preparation, can solve problems such as heavy weight, stress concentration, and inconsistent thermal expansion coefficients of metal and material shells, and achieve excellent mechanical properties and overcome heavy weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a method for preparing the wave-transparent composite material half cover, comprising the following steps:

[0040] Step 1: Lay 3 to 5 groups of prepregs of fiber and resin composite materials on the split mold of the metal male mold, assemble the split molds into one body, and precompact the prepregs to form prepreg ring ribs and Longitudinal structure;

[0041] Wherein, in the fiber and resin composite material, the volume fraction of the fiber is 57% to 63%, each group of fiber and resin composite material is laid by 4 layers of fiber and resin composite material, and the laying angle is 0 °, 90°, +θ°, -θ°, 30°≤θ≤60°, the laying thickness is 0.2mm, the laying cycle of the longitudinal ring reinforcement is generally 3-5 groups, and the number of cycles is generally based on the mechanical load of the product strength formulation;

[0042]The fiber is one of glass fiber, quartz fiber and high silica fiber, and the resin is one of ...

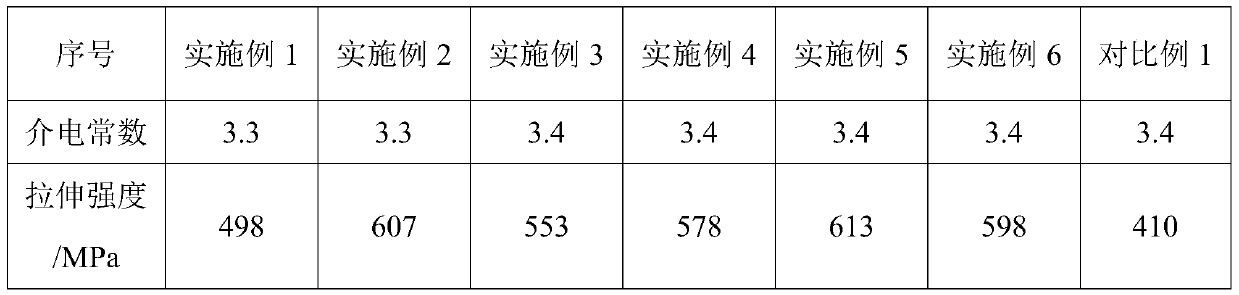

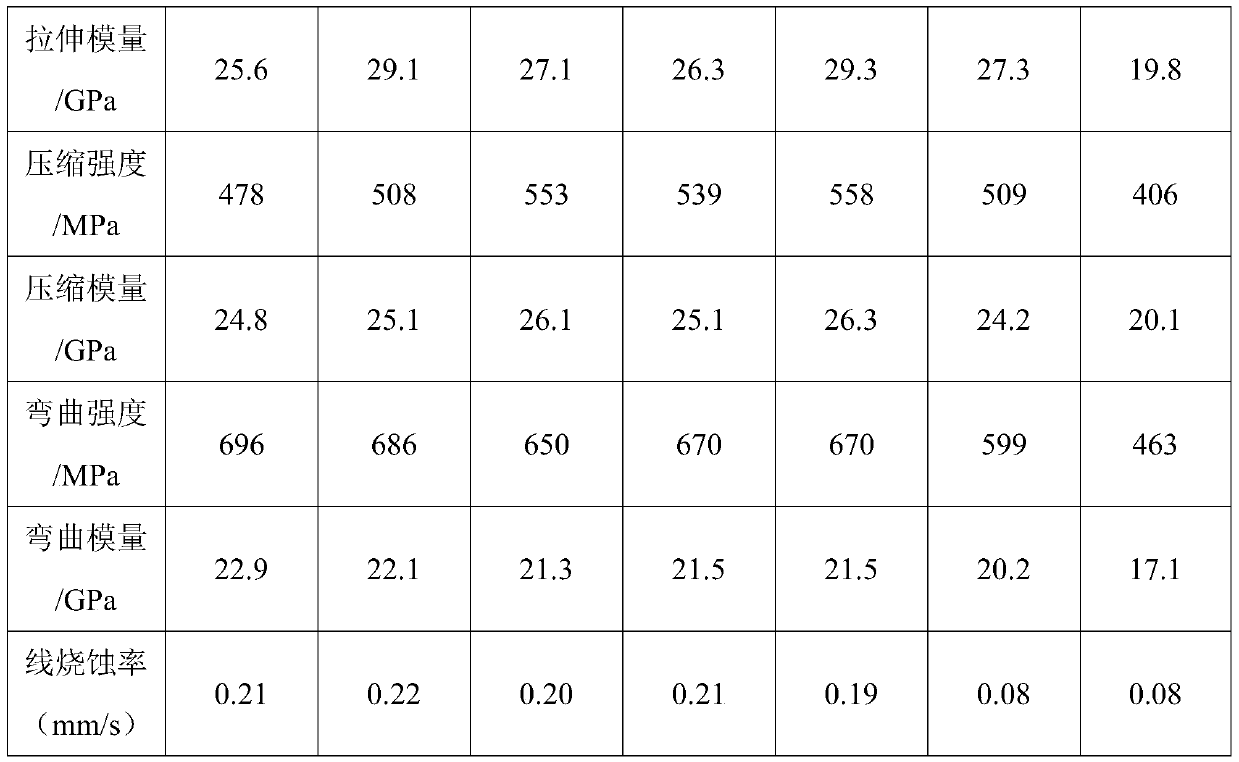

Embodiment 1

[0047] This embodiment provides a method for preparing a wave-transparent composite material half cover, including:

[0048] S1. Repeat laying 5 times according to the laying angle of 0°, 90°, +45°, -45° [0 / 90 / +45 / -45] 5 Lay-up sequence, lay glass fiber / cyanate resin prepreg on the metal male mold split mold, the thickness of each layer of prepreg is 0.2mm, then assemble the split mold into one, screw the split mold The connecting bolts between them pre-compact the prepreg to form a prepreg longitudinal ring reinforcement structure. In the glass fiber and cyanate ester composite material, the volume fraction of the glass fiber is 57%.

[0049] S2. According to the laying angle, it is 0°, 90°, +45°, -45°, repeat laying 6 times [0° / 90° / +45° / -45°] 6 Lay-up sequence, laying front and rear end frame reinforcement areas and flanges.

[0050] S3. According to the laying angles, they are 0°, 90°, +45°, -45°, repeat laying 8 times [0° / 90° / +45° / -45°] 8 The ply sequence of , lay down ...

Embodiment 2

[0054] This embodiment provides a method for preparing a wave-transparent composite material half cover, including:

[0055] S1. Repeat laying 4 times according to the laying angle of 0°, 90°, +30°, -30° [0 / 90 / +30 / -30 / ] 4 Layup sequence, lay quartz fiber / cyanate resin prepreg on the metal male mold split mold, the thickness of each layer of prepreg is 0.2mm, then assemble the split mold into one, and tighten the split mold The connecting bolts between them pre-compact the prepreg to form a prepreg longitudinal ring reinforcement structure. In the composite material of quartz fiber and cyanate ester, the volume fraction of the quartz fiber is 60%.

[0056] S2. According to the laying angles, they are 0°, 90°, +30°, -30°, repeat laying 6 times [0° / 90° / +30° / -30°] 6 Lay-up sequence, laying front and rear end frame reinforcement areas and flanges.

[0057] S3. According to the laying angles, they are 0°, 90°, +30°, -30°, repeat laying 8 times [0° / 90° / +30° / -30°] 8 The ply sequen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com