Method for preparing porous material of slow-release degradable film wrapped medicine fertilizer

A technology of porous materials and degradable films, applied in inorganic fertilizers, fertilizer mixtures, potash fertilizers, etc., can solve the problems of unsatisfactory long-term effect of fertilizers, variation and other biological pollution, complex processes, etc., to achieve large-scale production promotion, prolonged effective The effect of release period and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

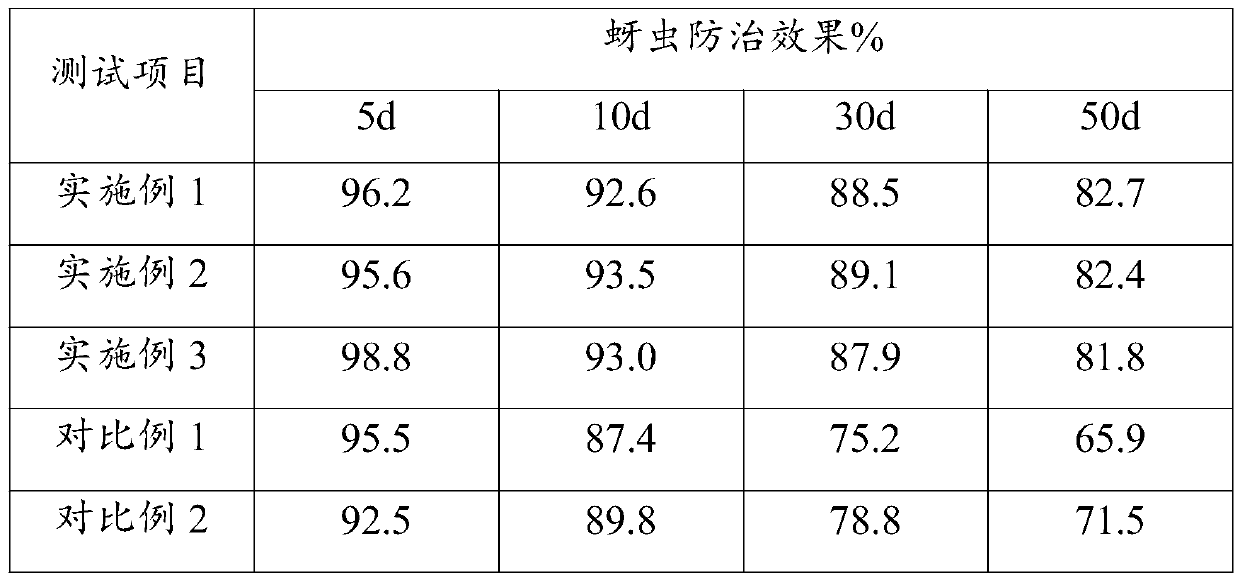

Embodiment 1

[0041] 1. Preparation of porous carbonized material:

[0042] 1) Weigh plant ash as raw material, dry at 70°C for 2 hours, mechanically pulverize, pass through a 10-mesh sieve, and superfinely pulverize through a 250-mesh sieve for later use;

[0043] 2) Weighing 45wt% of plant ash powder in proportion, 35wt% of a configured mass fraction of 8% potassium hydroxide alkali solution, and 20wt% of pore-enhancing agent 15% polyvinylpyrrolidone;

[0044] 3) Soak the pulverized plant ash in the mixed solution for 5 hours, put it into the drier for ammoniation and dispersion treatment with ammonia gas for 1 hour;

[0045] 4) Put the plant ash powder into the tube furnace for low-temperature carbonization, set the temperature to rise from 100°C / h to 300°C for 3 hours, during which the protective gas nitrogen is introduced, cooled to room temperature and taken out for later use.

[0046] 2. Pesticide loading of porous materials:

[0047] 1) Weigh 1500ml of 20% sodium pentachlorophenat...

Embodiment 2

[0059] 1. Preparation of porous carbonized material:

[0060] 1) Weigh plant ash as raw material, dry at 70°C for 2.5 hours, mechanically pulverize, pass through a 10-mesh sieve, and superfinely pulverize through a 250-mesh sieve for later use;

[0061] 2) Weigh 60wt% of plant ash powder in proportion, 30wt% of the configured mass fraction 8% potassium hydroxide alkali solution, and 10wt% of pore-enhancing agent 3% urea solution;

[0062] 3) Soak the pulverized plant ash in the mixed solution for 5 hours, put it into the drier for 1.5 hours for ammonification and dispersion treatment with ammonia gas;

[0063] 4) Put the plant ash powder into the tube furnace for low-temperature carbonization, set the temperature to rise from 100°C / h to 300°C for 3 hours, during which the protective gas nitrogen is introduced, cooled to room temperature and taken out for later use.

[0064] 2. Pesticide loading of porous materials:

[0065] 1) Weigh 1500ml of 20% sodium pentachlorophenate aq...

Embodiment 3

[0077] 1. Preparation of porous carbonized material:

[0078] 1) Weigh plant ash as raw material, dry at 73°C for 2 hours, mechanically pulverize, pass through a 10-mesh sieve, and superfinely pulverize through a 250-mesh sieve for later use;

[0079] 2) Weighing 55wt% of the plant ash powder in proportion, 30wt% of the configured mass fraction 8% potassium hydroxide alkali solution, and 15wt% of the pore-enhancing agent 3% urea solution;

[0080] 3) Soak the pulverized plant ash powder in the mixed solution for 5.5 hours, wash it with a large amount of distilled water until the pH value is 7-9, and put it into the dryer for 1.5 hours of ammonification and dispersion treatment with ammonia gas;

[0081] 4) Put the plant ash powder into the tube furnace for low-temperature carbonization, set the temperature to rise from 100°C / h to 300°C for 3 hours, during which the protective gas nitrogen is introduced, cooled to room temperature and taken out for later use.

[0082] 2. Pesti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com