System process method for fertilizer making through perishable garbage fermentation

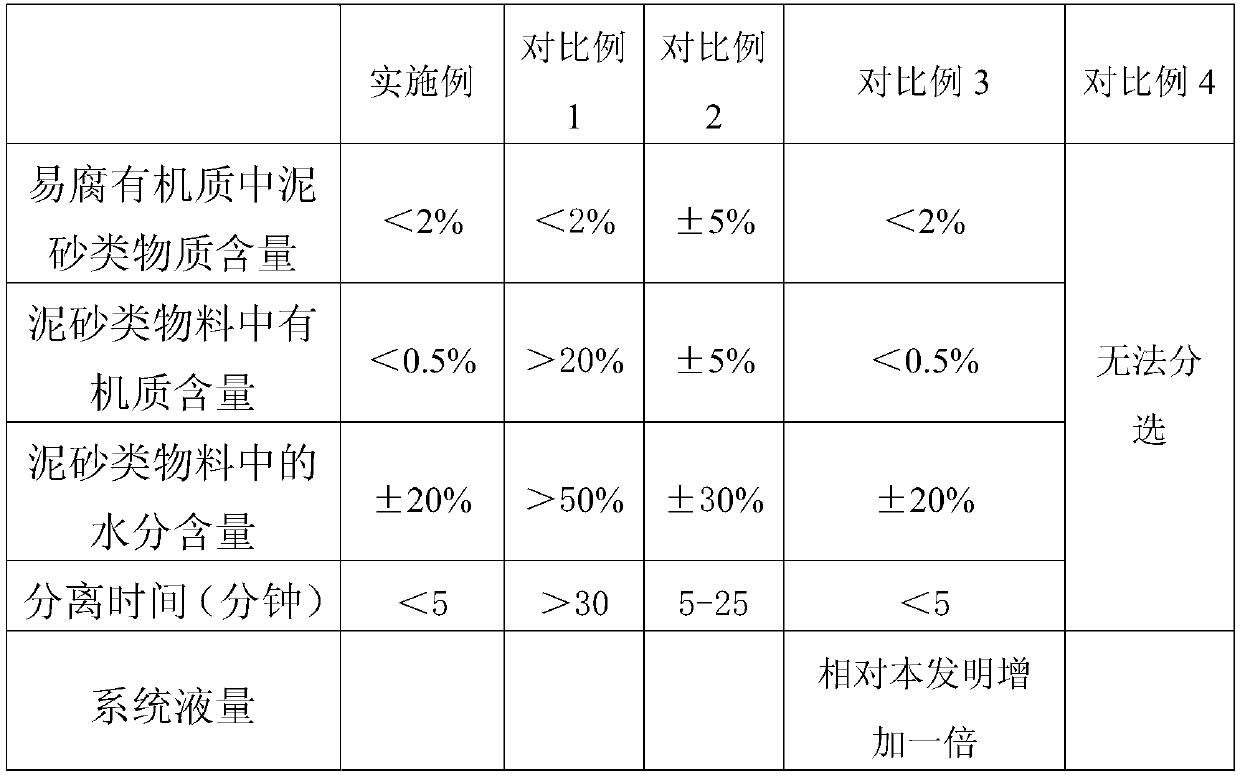

A process method and waste technology, which are applied in the fields of organic fertilizers, fertilization devices, and preparation of organic fertilizers, can solve the problems of high content of organic matter in mud and sand, inclusions, and difficult separation of mud and sand, and achieve and control the content of heavy metals, efficient separation, and reduction of heavy metals. The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025]A process method for fermenting perishable garbage, comprising the following steps:

[0026] 1) Shred the garbage to be processed to achieve full bag breaking, and screen to obtain garbage materials below 200mm, and sort out large pieces of garbage materials; then selectively crush the garbage materials below 200mm, only the easily Rotten organic matter and brittle inorganic matter, soft plastics, fabrics, rubber, and high-strength metals are not completely crushed, and the waste materials below 20mm are separated to obtain the initial separation of waste;

[0027] 2) Add water to the primary separation garbage obtained in step 1) to adjust its solid content to 8%, to prepare a slurry, continuously feed micron bubbles into the slurry, and under the action of the micron bubbles, fabrics, plastics, etc. The materials with light specific gravity float up, the mud sand and other inorganic materials with large specific gravity settle, and the perishable organic matter is susp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com