Novel material for high-strength electric ceramies and preparation method of novel material

A new type of material and high-strength technology, applied in applications, household utensils, clay products, etc., can solve the problems of large dispersion of mechanical strength, unstable cold and hot performance, and inability to realize raw materials, etc., to achieve improved porcelain structure and uniformity properties, reduction of structural defects, reduction of iron impurities and free quartz content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A new type of material for high-strength electric porcelain, the composition range of the formula is as follows: calcined industrial alumina powder 5%, calcined mullite powder 30%, kaolin and bonded clay 30%, super potassium feldspar powder 20%, additives 1%.

[0027] Based on the above-mentioned material formula, a preparation method of a new material for high-strength electric porcelain is proposed, including the following steps:

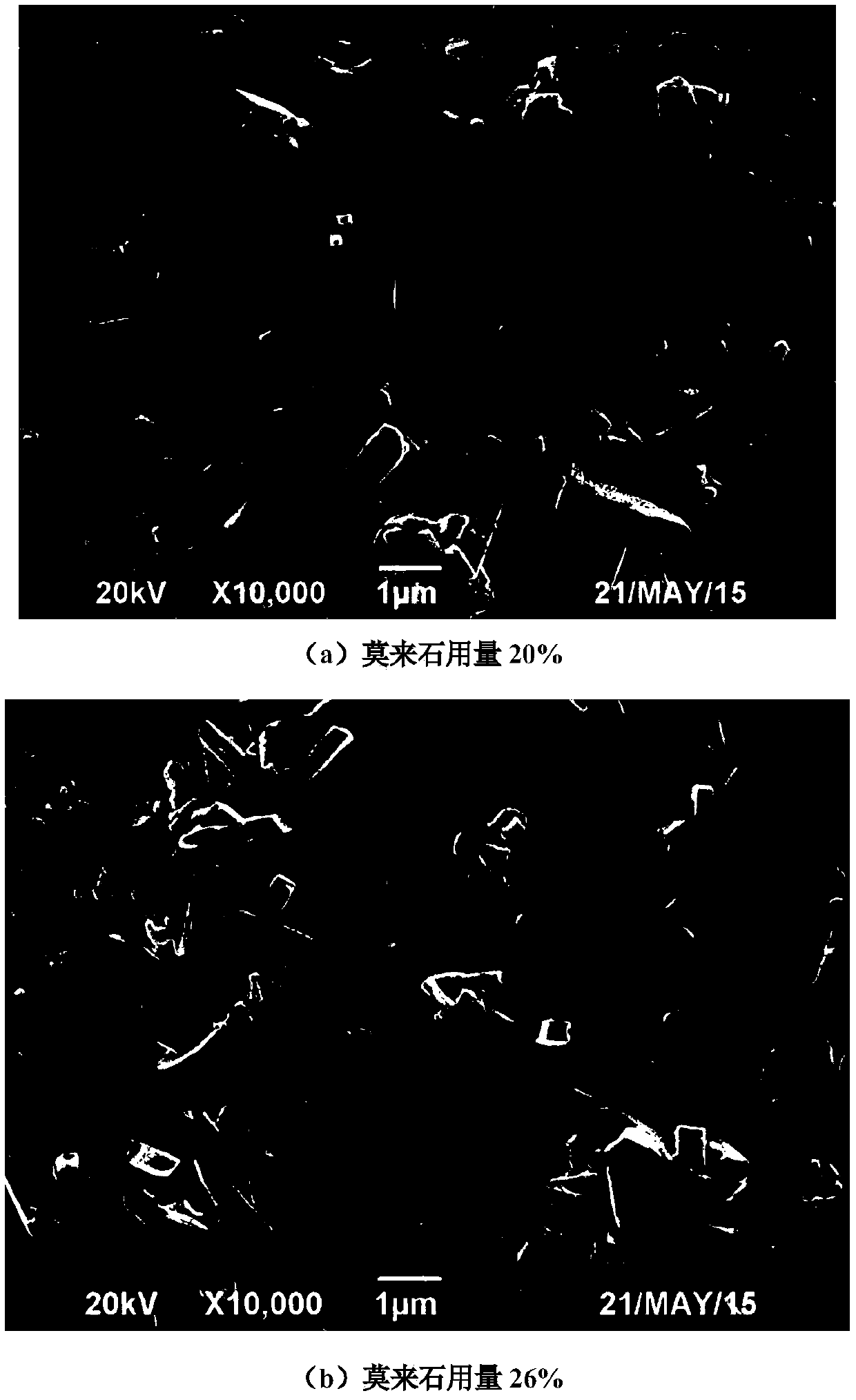

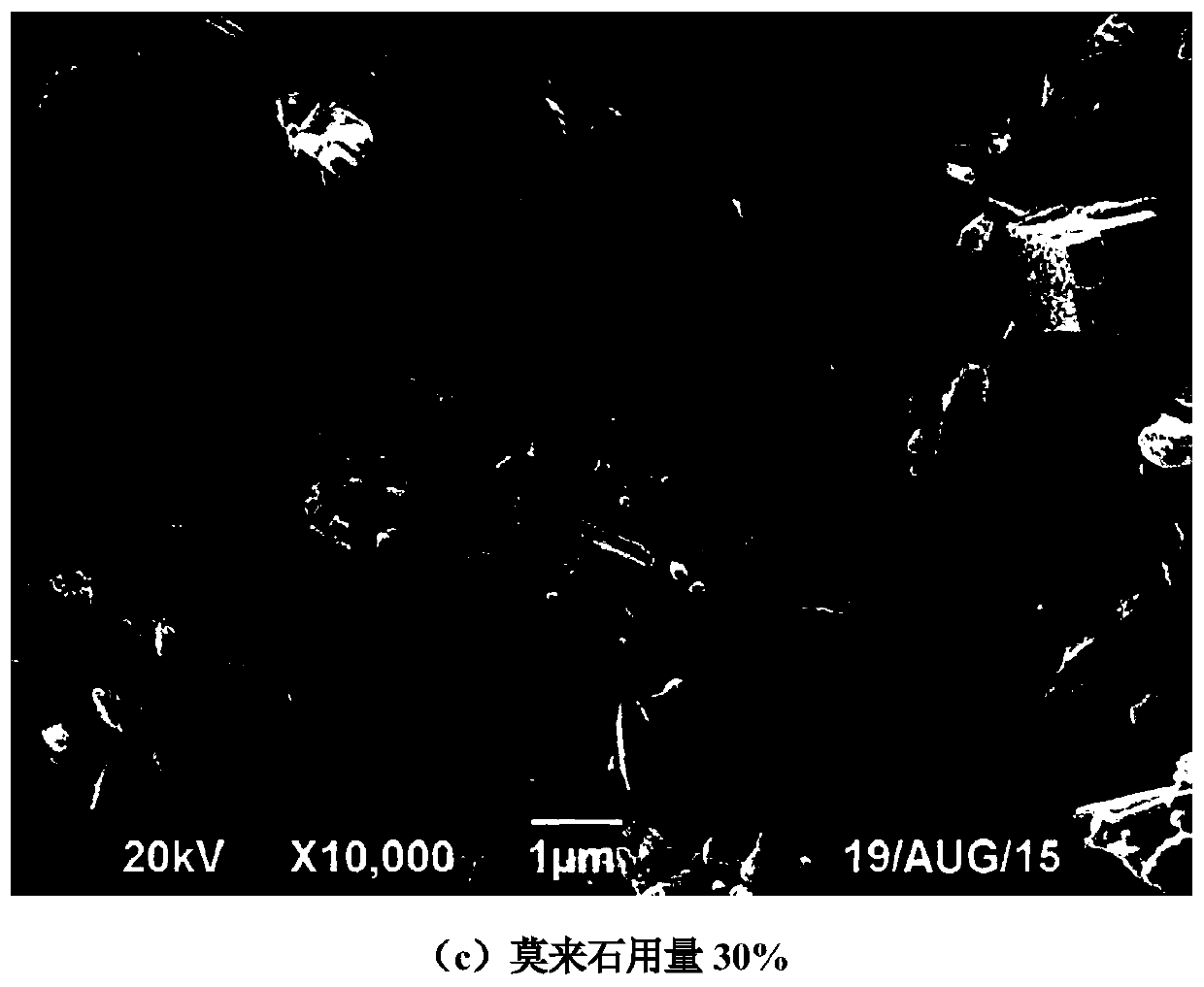

[0028] Step 1: Use ball milling equipment to grind the obtained calcined mullite into powder, sieve, select the washed kaolin and super potassium feldspar, also use ball milling equipment to grind into powder, and sieve, use mullite resources, reduce The amount of calcined industrial alumina, through the synergistic reinforcement mechanism of mullite phase and corundum phase, realizes the high strength and high reliability of electric porcelain materials, uses eluted kaolin to replace natural clay minerals, and reduces iron impurities and fr...

Embodiment 2

[0033] A new material for high-strength electric porcelain, the composition range of the formula is as follows: calcined industrial alumina powder 10%, calcined mullite powder 25%, kaolin and bonded clay 25%, super potassium feldspar powder 18%, additives 3%.

[0034] The preparation method of this example is the same as the steps of Example 1, and will not be repeated here.

Embodiment 3

[0036] A new type of material for high-strength electric porcelain, the formula composition range is as follows: calcined industrial alumina powder 15%, calcined mullite powder 20%, kaolin and bonded clay 20%, super potassium feldspar powder 15%, additives 5%.

[0037] The preparation method of this example is the same as the steps of Example 1, and will not be repeated here.

[0038] Calcined mullite is selected from mullite in Xiangxi Autonomous Prefecture, Hunan Province. It is a mineral produced by aluminosilicate at high temperature. It has a large amount. Mullite will be formed when aluminosilicate is artificially heated. Natural mullite crystals are elongated needles in radial clusters. Mullite AI203-SI02 elemental system is the only stable binary compound under normal pressure. The chemical formula is 3AI203-2SI02. There are very few natural mollites, which are usually artificially synthesized by sintering or capacitance methods. Chemical formula A1xSi2-xO5.5-0.5x den...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com