Ampoule bottle breaking device

A technology of breaker and ampoules, which is applied in the directions of bottle/container cap, bottle filling, opening and closing containers, etc., can solve the problems of inability to sterilize ampoules, particles easily entering the bottle, and easily generating debris, etc. The number of hand changes, the structure is simple, and the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

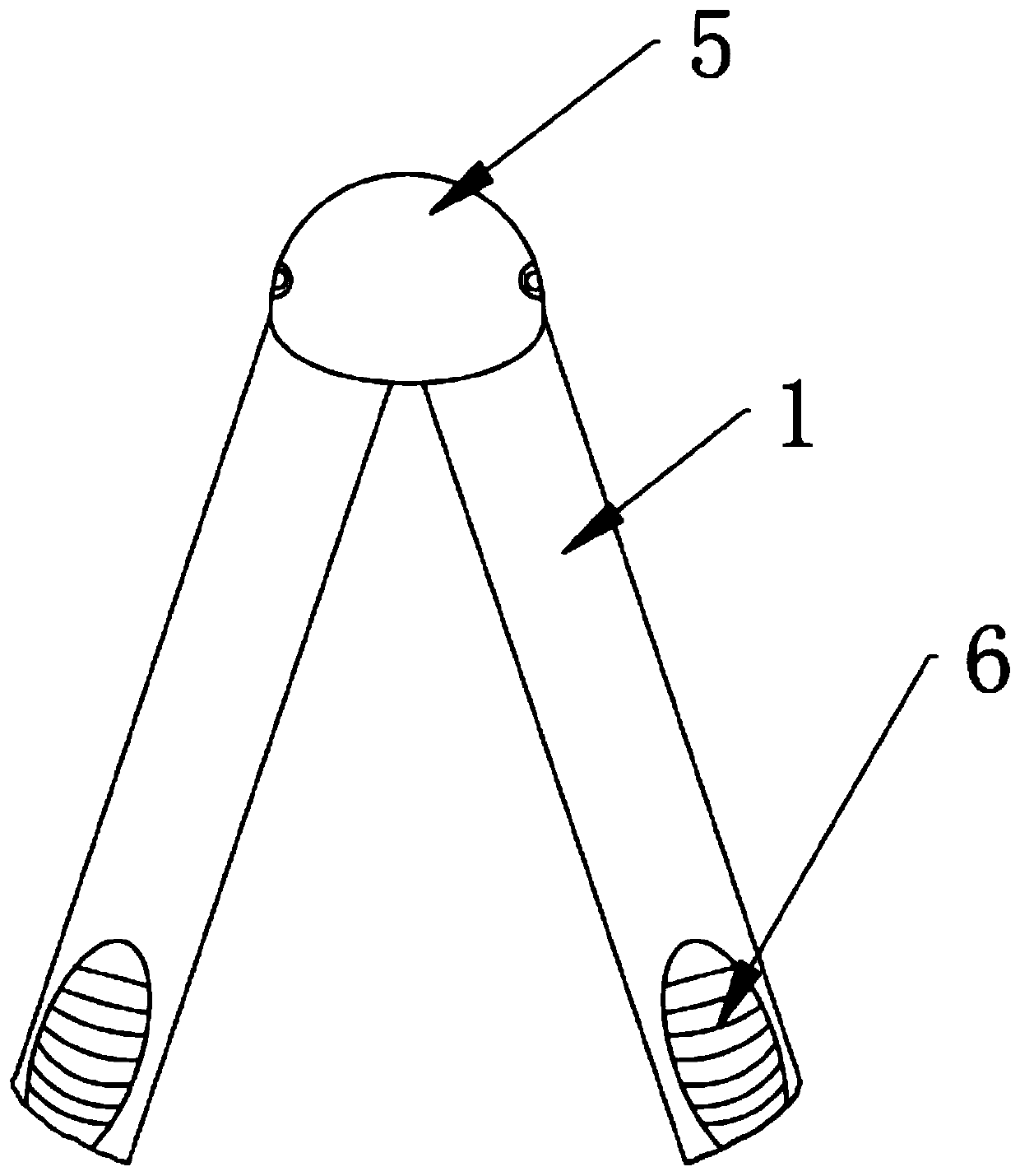

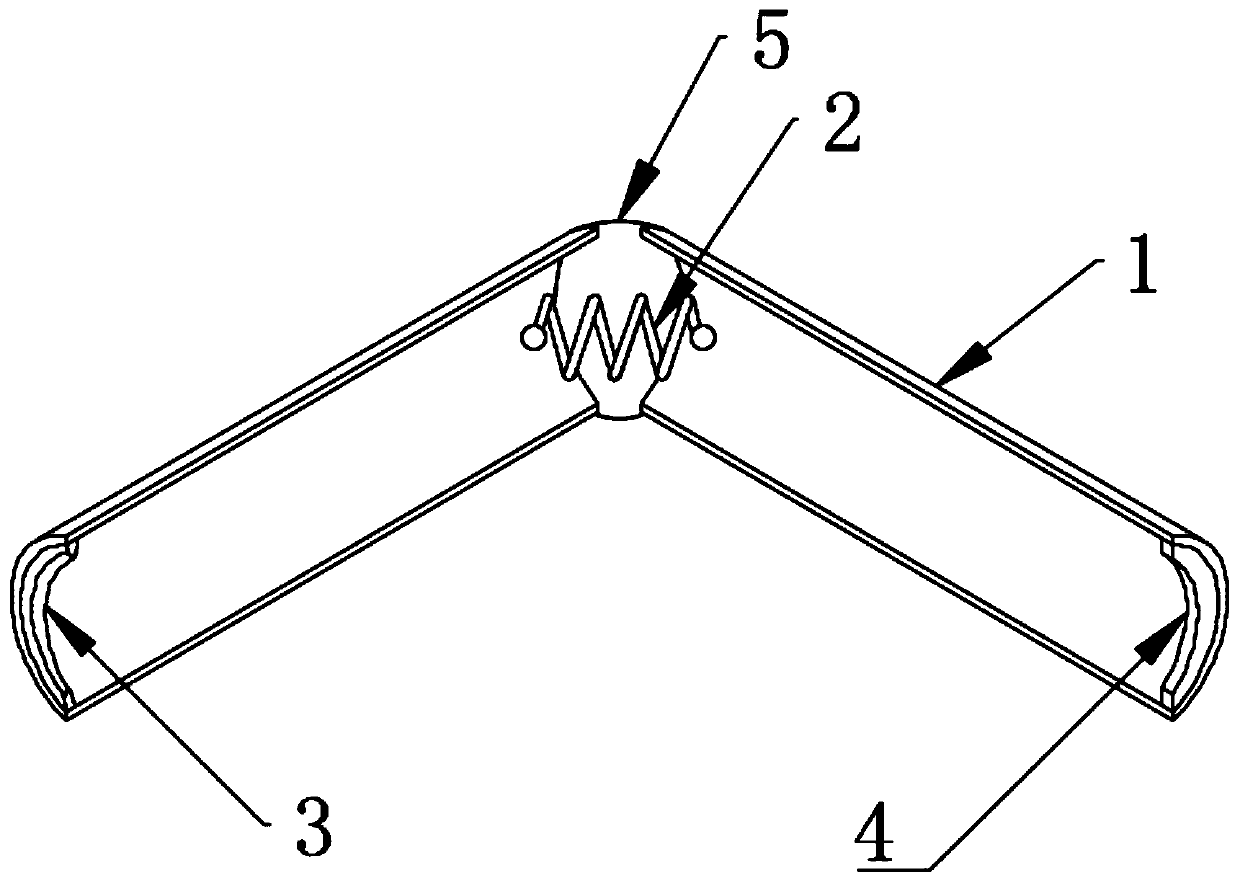

[0022] Such as figure 1 , 2 1. The ampoule breaker shown in 3 includes splints 1 connected at the upper ends, and the opposite surfaces of the two splints 1 are clamping surfaces; at least one of the clamping surfaces of the splints 1 is embedded with a crescent-shaped grinding wheel 3 or at least The lower end of the clamping surface of one of the splints 1 is provided with a protrusion for wearing hard objects (such as glass ampoules). In this embodiment, a crescent-shaped grinding wheel 3 is embedded in the inner wall of the lower end of one splint 1 , and a sponge or composite material 4 is installed at the lower end of the other splint 1 opposite to the grinding wheel 3 .

[0023] The inner walls at the upper ends of the two splints 1 are connected by a spring 2 . The upper ends of the two splints 1 are also covered with hinged caps 5; both sides of the hinged caps 5 are hinged to the two splints 1 respectively.

[0024] In this embodiment, the clamping surface or the ...

Embodiment 2

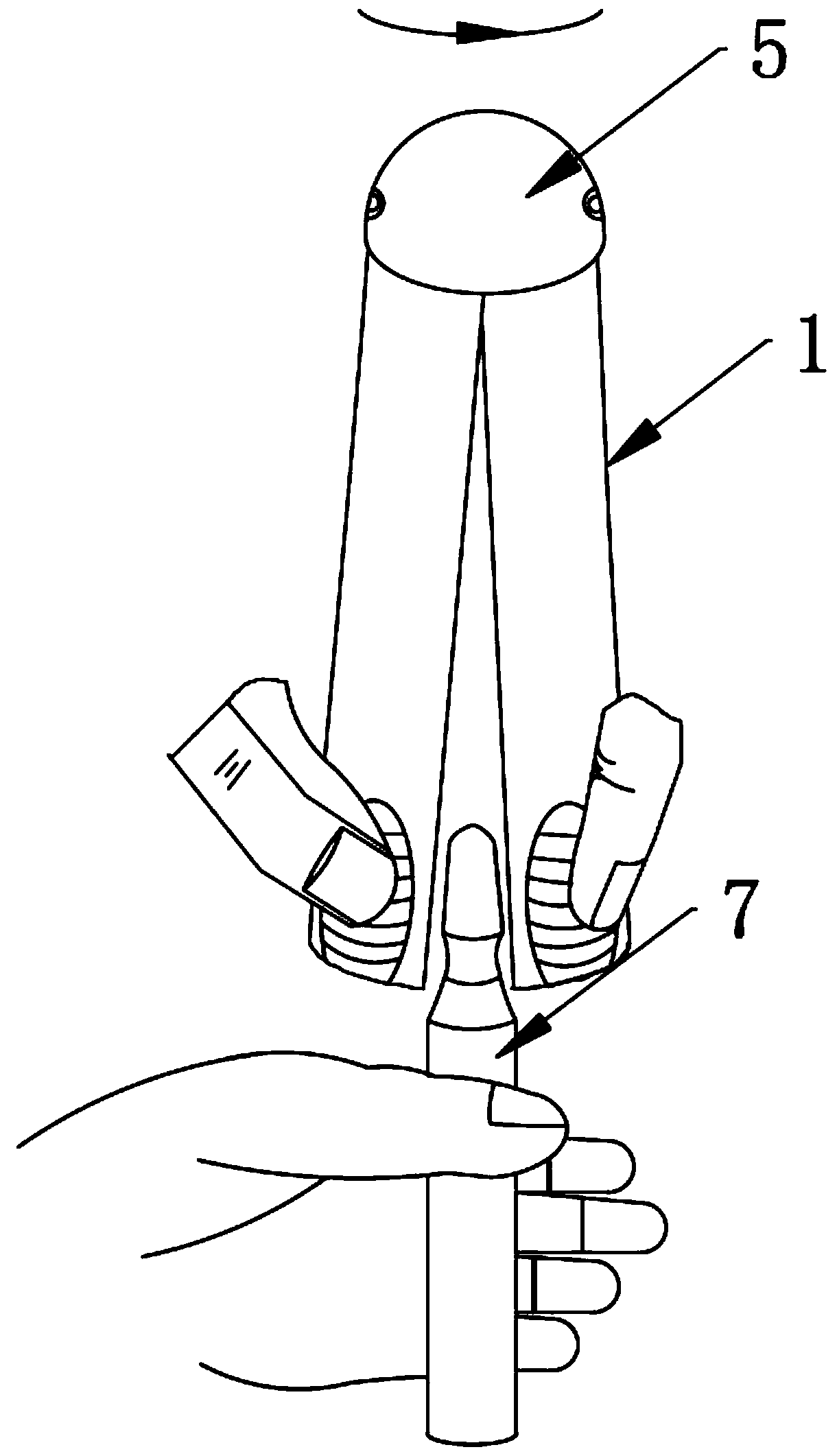

[0029] Such as Figure 4 As shown, the structure of the ampoule breaker of the present embodiment 2 is substantially the same as that of the embodiment 1, the difference is that the upper ends of the two splints 1 are hinged; a hinged cap 5 covering the upper ends of the two splints 1 is also included; the two splints The upper ends of 1 are respectively connected to two opposite inner walls of the hinge cap 5 through a spring 2 . The difference between this embodiment and embodiment 1 is that two springs 2 are provided, and each splint 1 corresponds to a spring 2 connected to the hinged cap 5. This design makes the clamping times of the breaker more, and the spring 2 wears less. Small, more durable, and the two splints 1 are in the normal open state. When in use, align the neck of the ampoule 7 and clamp the two splints 1 to rotate at least one turn before breaking the ampoule 7. At this time, clamp The splint 1 clamps the part above the neck of the ampoule 7, and the breake...

Embodiment 3

[0031] Such as Figure 5 As shown, the structure of the ampoule breaker in Embodiment 3 and Embodiment 2 is roughly the same, the difference is that the hinged cap 5 and the spring 2 are removed; the upper ends of the two splints 1 are directly connected as one or the two splints 1 are directly integrally formed. ; The splint 1 is a splint made of elastic material, and the junction of the upper ends of the splint 1 is provided with a protrusion 8 for keeping the two splints 1 apart. The protrusions 8 of the two splints 1 are arranged opposite to each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com