Medicine packaging box glue-coating surface breaking device

A box gluing and surface breaking technology, applied in the field of packaging box manufacturing equipment, can solve the problems of low adhesion, easy release, poor adhesion, etc., and achieve the effect of good adhesion and not easy to release.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

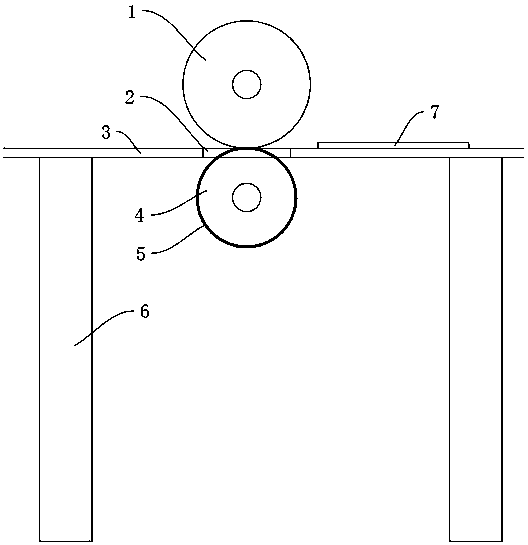

[0025] Such as figure 1 figure 2 image 3 As shown in the figure, a device for breaking the glued surface of a pharmaceutical packaging box includes a workbench 3 supported by legs 6, a pressing wheel 1 and a breaking wheel 4 arranged up and down relative to the workbench. The face wheel is under the workbench, and the axis of rotation of the pressing wheel and the face-breaking wheel is parallel, and the workbench is provided with a gap 2, and the periphery of the face-breaking wheel just corresponds to the position of the gap. The outer circumference of the face-breaking wheel is provided with a face-breaking tooth 5, and the face-breaking tooth stretches out on the workbench from the gap.

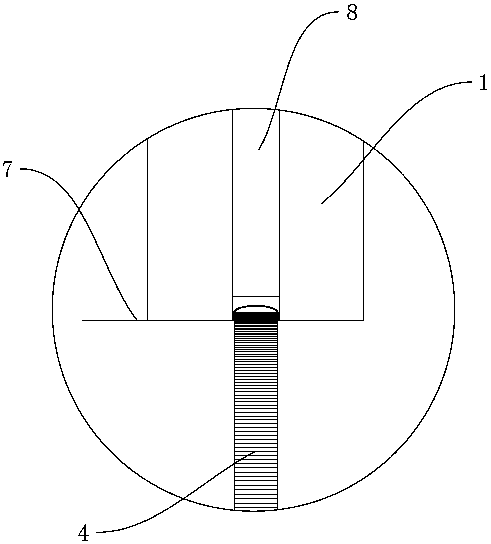

[0026] The main body of the pressure roller is metal, and there is a convex ring on the outer circumference of the metal main body. Two rubber rings are fixed on the outer circumference of the pressure wheel. 8. The face breaking wheel faces the groove, and the face breaking teeth o...

Embodiment 2

[0032] Such as Figure 4 Figure 5 As shown, a drug packaging box glue coating surface breaking device, the difference from Example 1 is:

[0033] The middle part of the tooth top of the face-breaking tooth is concave to form a face edge 10, and the two ends of the tooth top form an inclined face-breaking edge 9, which is inclined, and the face-breaking edge extends from both sides of the face edge to the breaking edge. The end point of the tooth. The two ends of the addendum are the blade tips 11 of the broken face blade. There is an inclined rear edge face 12 between the broken face edge and the rear tooth surface, and the angle of the rear edge face relative to the front tooth surface is controlled at 35°. Refer to Example 1 for all the other structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com