Segmental beam bottom mold system

A segmental beam and bottom mold technology, applied in molds, auxiliary molding equipment, ceramic molding machines, etc., can solve the problems of low utilization rate of bottom molds and high cost of templates, and achieve convenient application control, reasonable structure design, and bottom mold utilization. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment is used for segmental prefabrication of long-span variable-section continuous beams. The section height of long-span variable-section continuous beams changes along the longitudinal direction of the bridge, and the vertical height of the bottom of the beam body is in the shape of a parabola or arc along the longitudinal direction. The main advantages of using segmental prefabrication compared with traditional box girder are:

[0028] 1) The beam section is small in size and convenient for transportation, and general roads can meet the transportation requirements of segmental beams;

[0029] 2) The concrete shrinkage and creep of the segmental beam is small, and the line shape of the beam body does not change much after completion;

[0030] 3) Factory-like prefabricated production of segmental beams is convenient for production organization and overall construction quality control; centralized prefabricated production of segmental beams is beneficial to p...

Embodiment 2

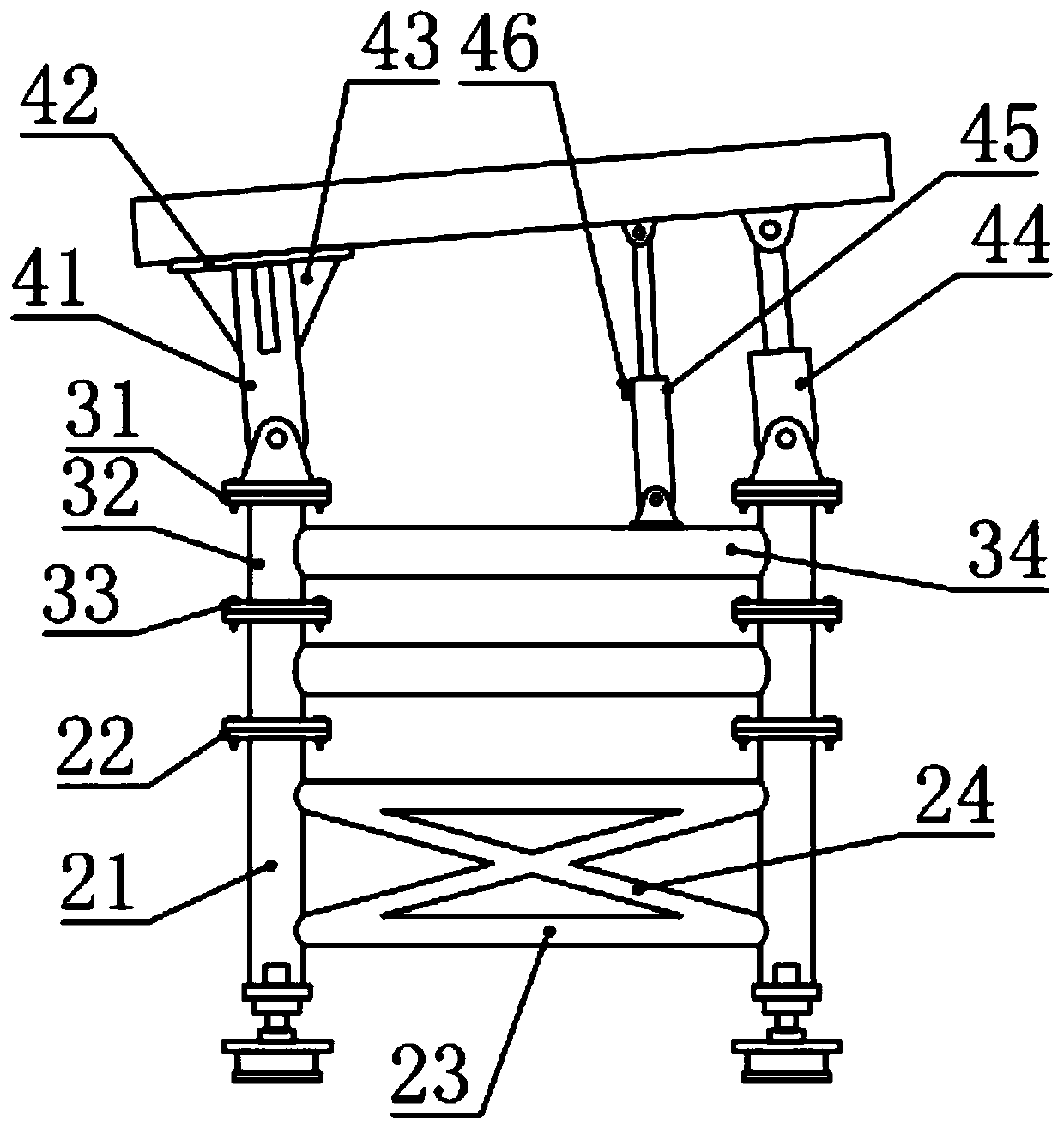

[0034] see Figure 3-5 , the difference between this embodiment and embodiment 1 is:

[0035] In this example, if figure 2 As shown, the base support 2 includes a column 21, a first connecting flange 22, a beam 23 and an X beam 24, the column 21 is provided with two, and the fine-tuning seat 1 is installed on the lower ends of the two columns 21, and the two columns The upper end of 21 is installed and fixed with the first connection flange 22 that is used for being connected and fixed with elevated bracket 3; Also installed and fixed with crossbeam 23 and X beam 24 between two described columns 21, specifically, the X beam 24 A crossbeam 23 is respectively arranged on the upper and lower sides, and the ends of the crossbeam 23 and the X-beam 24 are welded and fixed with the column 21 .

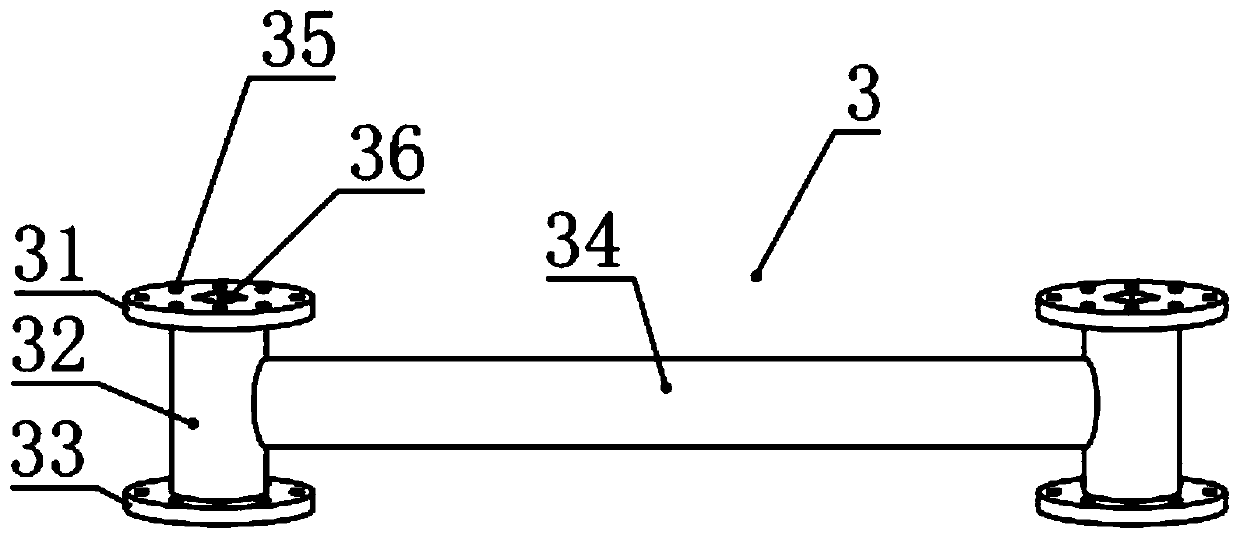

[0036] In this example, if figure 2 with 3 As shown, the elevated support 3 includes a second connection flange 31, a support beam 32, a third connection flange 33 and a tension beam 34, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com