Automatic pastry production line

A production line and noodle point technology, which is applied in the direction of rolling dough sheet machine, dough cutting machine, dough forming and cutting combination, etc., can solve the problem of incomplete and uniform gluten network, unmatched dough belt conveying, low degree of automation and low efficiency and other problems, to achieve the effect of complete and uniform gluten network, accurate product weight and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

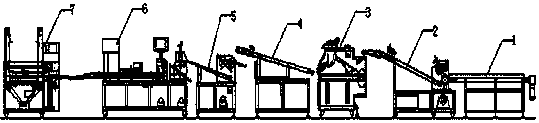

[0028] An automatic noodle production line, the noodle block conveying device 1 transports the reconciled noodle block to the pre-pressing and dividing device 2, and divides it into several noodle strips, and the subsequent strips enter the continuous noodle pressing device 3, which is automatically realized by the continuous noodle pressing device 3 Folding and rolling several times in "S" shape, and then output the dough band with set length and thickness into the dough band transition device 4, the dough band is sent to the dough band lapping device by the dough band transition device, and the dough band is lapped by the dough band The connecting device rolls again, and the rolled dough strip enters the pastry forming device, and in the pastry forming device, it passes through two layers of pressing, rolling, and cutting to form pastry products, and finally enters the automatic plate arrangement machine to place the plate , proofing, steaming.

[0029] Such as figure 1 As ...

Embodiment 2

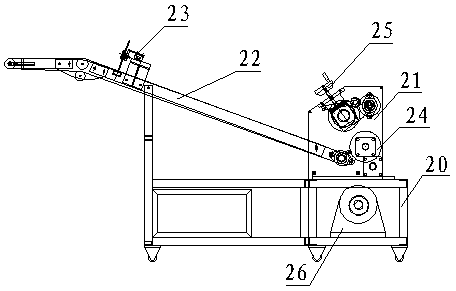

[0031] Such as figure 2As shown, as a part of the specific structural design of embodiment example 1, the pre-pressing and dividing device 2 includes a pre-pressing and dividing frame 20, a pressing unit 21 installed on the pre-pressing and dividing frame 20, and the feed end is located at the pressing unit. 21 The pre-pressing and dividing conveying unit 22 at the output end, the roll cutting unit 23 installed on the pre-pressing and dividing conveying unit 22; The adjustable slave pressing roller 25 in the upper part of the unit housing, the adjustable slave pressing roller 25 includes a slave pressing roller and a slave pressing roller adjusting frame for installing the slave pressing roller, and the slave pressing roller adjusting frame is installed on the pressing surface In the top of the unit housing, the main pressing roller 24 is connected to the pressing motor 26; the hobbing unit 23 includes a hobbing unit frame, the hobbing knife is installed on the hobbing knife ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com