Variable-bar-diameter Hopkinson pressure bar experimental device and method

A Hopkinson pressure bar and experimental device technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of high cost of SHPB devices, waste of laboratory land resources, and increased economic costs, and achieve significant scientific research and engineering. Application significance, easy installation, and the effect of reducing experimental errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

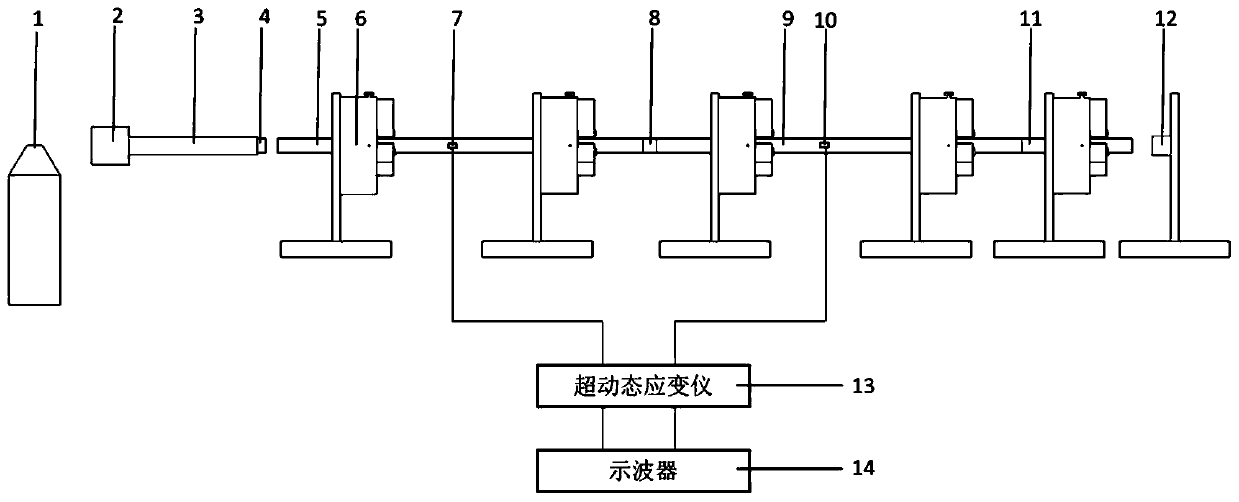

[0044] Step 1: Place the incident rod 5, the transmission rod 9 and the absorption rod 11 made of high-strength silicon-manganese steel with a diameter of 100 mm and a length of 4000 mm, 4000 mm and 1000 mm respectively in the three-jaw chuck 6, between the three-jaw chuck 6 Keep an appropriate distance between them, such as 800mm, to reduce the influence of the self-weight of the experimental rod on the experiment;

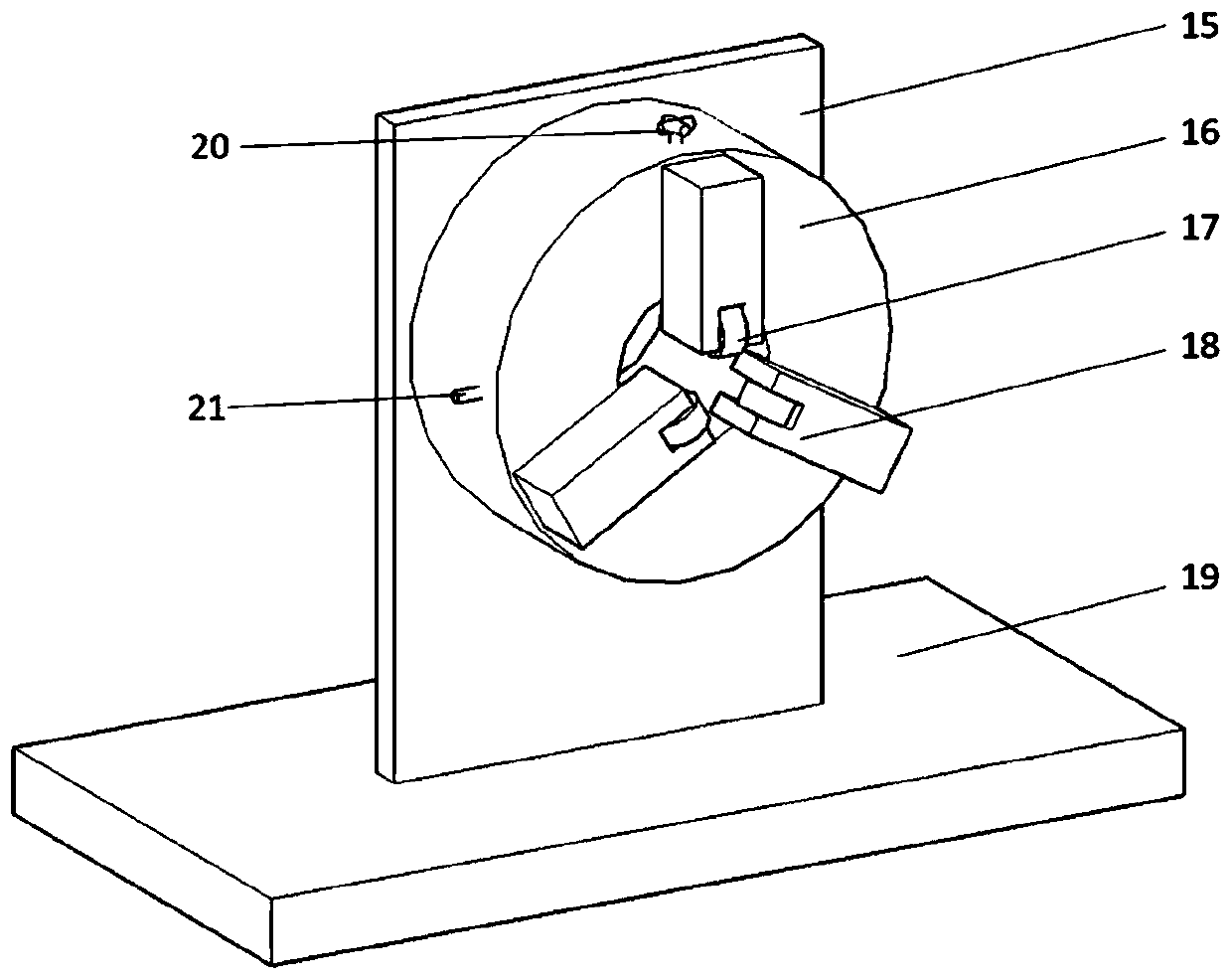

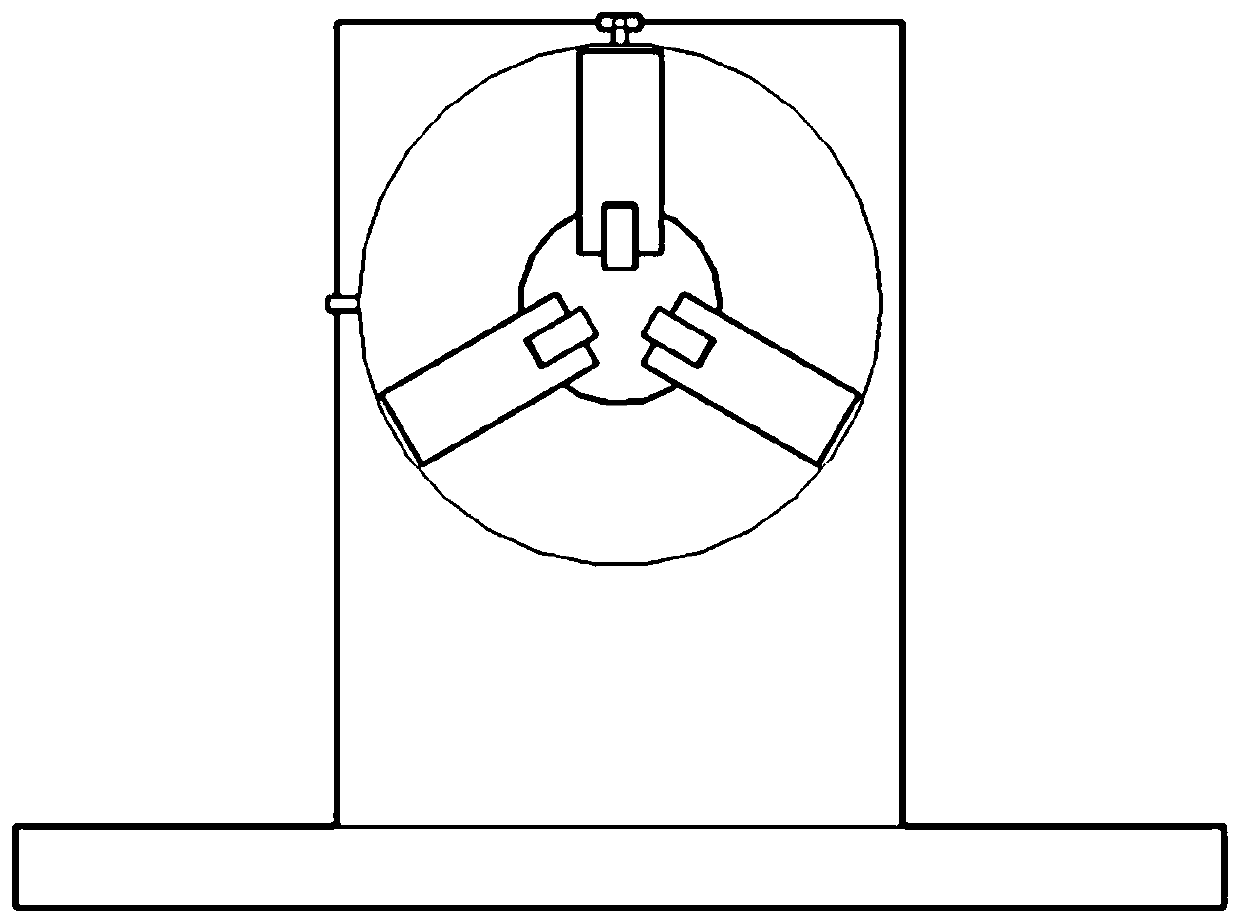

[0045] Step 2: Radially adjust the three-jaw chuck 6 through a pneumatic device (or manual adjustment valve 20), so that the incident rod 5, the transmission rod 9 and the absorption rod 11 are on the same axis and can slide smoothly;

[0046] Step 3: Paste the incident rod strain gauge 7 and the transmission rod strain gauge 10 at the central positions of the incident rod 5 and the transmission rod 9, and connect them with the ultra-dynamic strain gauge 13 and the oscilloscope 14, and ensure that the circuit is unobstructed;

[0047] Step 4: After the completion...

Embodiment 2

[0052] Step 1: The incident rod 5, the transmission rod 9 and the absorption rod 11 made of high-strength silicon-manganese steel with a diameter of 38mm and a length of 2000mm, 2000mm and 500mm are placed in the three-jaw chuck 6, and the three-jaw chuck 6 is kept between them. Appropriate spacing, such as 1000 mm, to reduce the influence of the experiment rod's own weight on the experiment;

[0053] Step 2: Radially adjust the three-jaw chuck 6 through a pneumatic device (or manual adjustment valve 20), so that the incident rod 5, the transmission rod 9 and the absorption rod 11 are on the same axis and can slide smoothly;

[0054] Step 3: Paste the incident rod strain gauge 7 and the transmission rod strain gauge 10 at the central positions of the incident rod 5 and the transmission rod 9, and connect them with the ultra-dynamic strain gauge 13 and the oscilloscope 14, and ensure that the circuit is unobstructed;

[0055] Step 4: After the completion of the step 3, carry ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com