Ribbed beam floor system mold shell filling system

A filling system, rib beam building technology, applied in the direction of floors, building components, buildings, etc., can solve the problems of poor visual effect, mismatched modulus, wrong platform and slurry leakage, saving labor and material costs, reducing The use of wood, the effect of easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

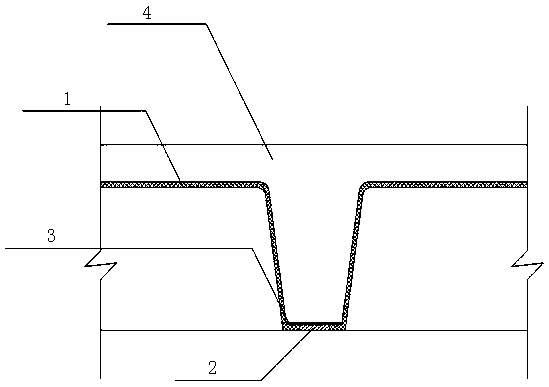

[0019] Such as figure 1 Shown: a filling system between the formwork of a rib-beam floor, including the following steps:

[0020] Step 1: Lay the wooden formwork, set out the installation position of the formwork and position it, and brush the release agent on the outside of the formwork 1;

[0021] Step 2: Install the formwork on the wooden formwork and fix the lower edge;

[0022] Step 3: Fill and level the gap within the thickness range of the formwork between the bottom edges of the adjacent formwork with low-strength mortar 2 or lay the upper part of the wooden formwork first and then level it with mortar;

[0023] Step 4: After the mortar is hardened, lay a strip-shaped soft insulating material isolation layer 3 with a certain hardness on the upper part of the mortar and the bottom of the formwork, generally using floor leather, and at least one side of the isolation layer is a smooth surface. With the smooth side up, apply glue along the lower sides of both sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com