Paper-based material for straw

A straw and paper-based technology, which is applied to the field of paper-based materials for straws, can solve the problems of easy moulding of paper tubes, low soaking strength of paper tubes and easy breakage, etc., and achieves bright and bright colors, rich and beautiful patterns, and outstanding layering. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

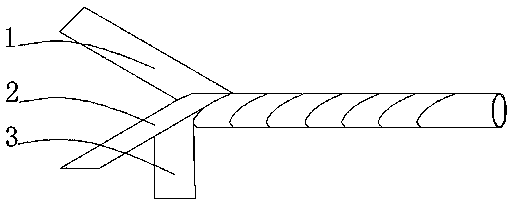

Image

Examples

Embodiment 1

[0023] This embodiment provides a production method involving paper-based materials for straws, comprising the following steps:

[0024] (1) Three types of wood pulp are obtained by beating the surface paper raw materials, middle paper raw materials and bottom paper raw materials respectively, wherein the surface paper raw materials are composed of 20% of coniferous fibers and 80% of broad-leaved eucalyptus fibers according to weight percentage, and the middle paper The composition of raw materials and bottom paper raw materials according to weight percentage is 25% of coniferous fibers and 75% of eucalyptus fibers; the beating concentration is 3.8%, and the beating degree / wet weight is 35°SR / 2.5g.

[0025] (2) After the beating treatment, add additives to the three kinds of wood pulp respectively, and carry out online forming treatment; add 5kg / t paper neutral sizing agent alkyl ketene dimer, 10kg / t paper pulp to the surface paper wood pulp The wet strength agent polyamide-ep...

Embodiment 2

[0032] (1) Three types of wood pulp are obtained by beating the surface paper raw materials, middle paper raw materials and bottom paper raw materials respectively, wherein the surface paper raw materials are composed of 25% of coniferous fiber and 75% of broad-leaved eucalyptus fiber according to weight percentage, and the middle paper The composition of raw materials and bottom paper raw materials according to weight percentage is 27% of coniferous fibers and 73% of broad-leaved eucalyptus fibers; the beating concentration is 3.9%, and the degree of percussion / wet weight is 40°SR / 3.0g.

[0033] (2) After the beating treatment, add additives to the three kinds of wood pulp respectively, and carry out online forming treatment; add 8kg / t paper neutral sizing agent alkyl ketene dimer, 15kg / t paper to the surface paper wood pulp The wet strength agent polyamide-epichlorohydrin modified resin of t paper and the cationic starch reinforcing agent of 3kg / t paper, add the neutral appli...

Embodiment 3

[0040] (1) Three types of wood pulp are obtained by beating the surface paper raw materials, middle paper raw materials and bottom paper raw materials respectively, wherein the surface paper raw materials are composed of 30% of coniferous fibers and 70% of broad-leaved eucalyptus fibers according to weight percentage, and the middle paper The composition of the raw material and the bottom paper raw material is 30% of coniferous fiber and 70% of broad-leaved eucalyptus fiber according to the weight percentage; the beating concentration is 4.0%, and the beating degree / wet weight is 45°SR / 3.5g.

[0041](2) Add additives to the three kinds of wood pulp after beating treatment, and carry out online forming treatment; add 10kg / t paper neutral sizing agent alkyl ketene dimer, 20kg / t paper pulp to the surface paper wood pulp The wet strength agent polyamide-epichlorohydrin modified resin of t paper and the cationic starch strengthening agent of 5kg / t paper, the neutral application agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cobb value | aaaaa | aaaaa |

| Cobb value | aaaaa | aaaaa |

| Cobb value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com