A New Cyclodextrin Polymer with Ultra-fast Adsorption Performance

A technology of cyclodextrin polymer and cyclodextrin, which is applied in the direction of solid adsorbent liquid separation, other chemical processes, separation methods, etc., can solve the problems of slow adsorption rate of organic pollutants and restrictions on industrial production, and achieve rapid removal, The effect of fast adsorption performance and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

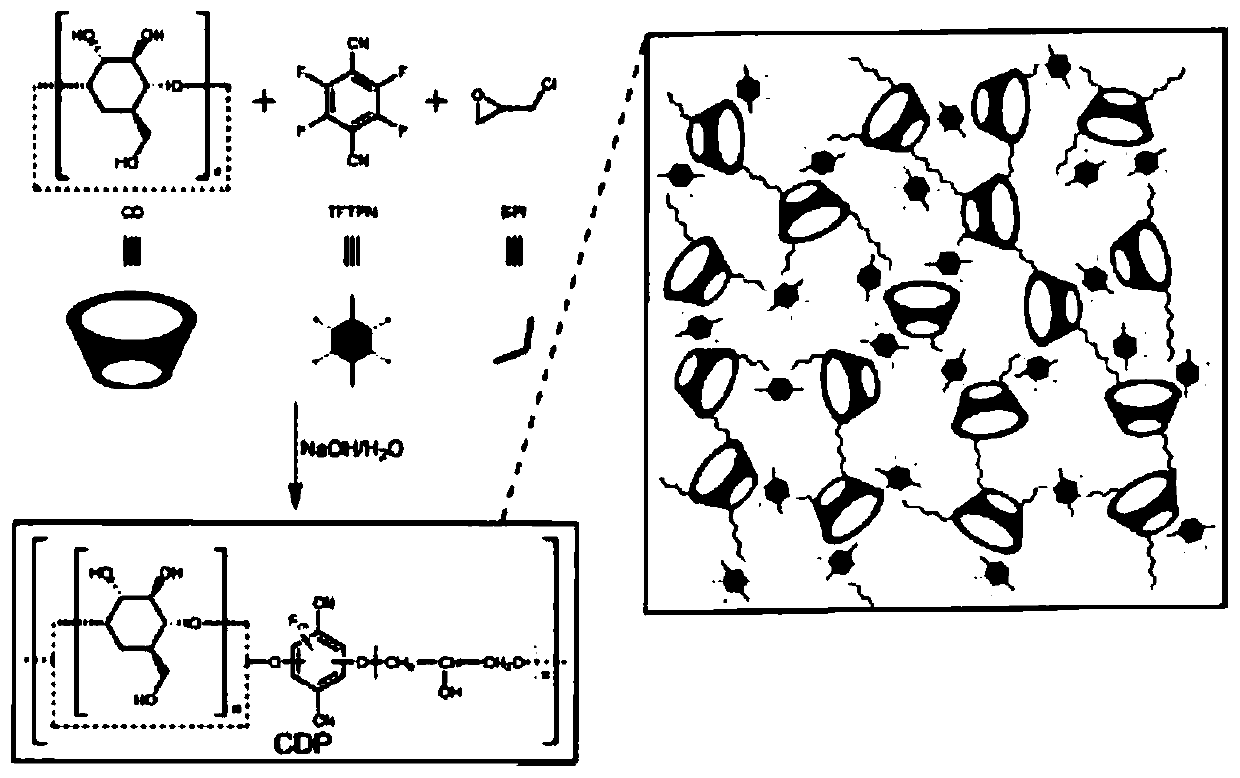

Method used

Image

Examples

Embodiment

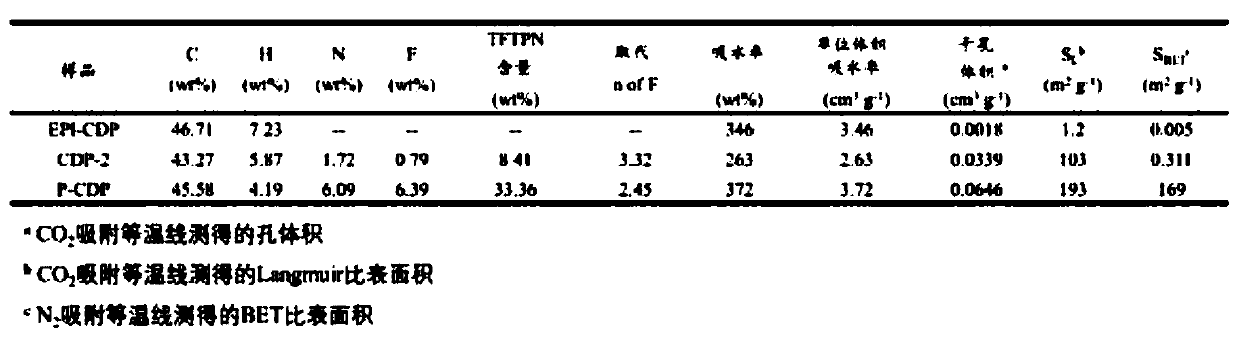

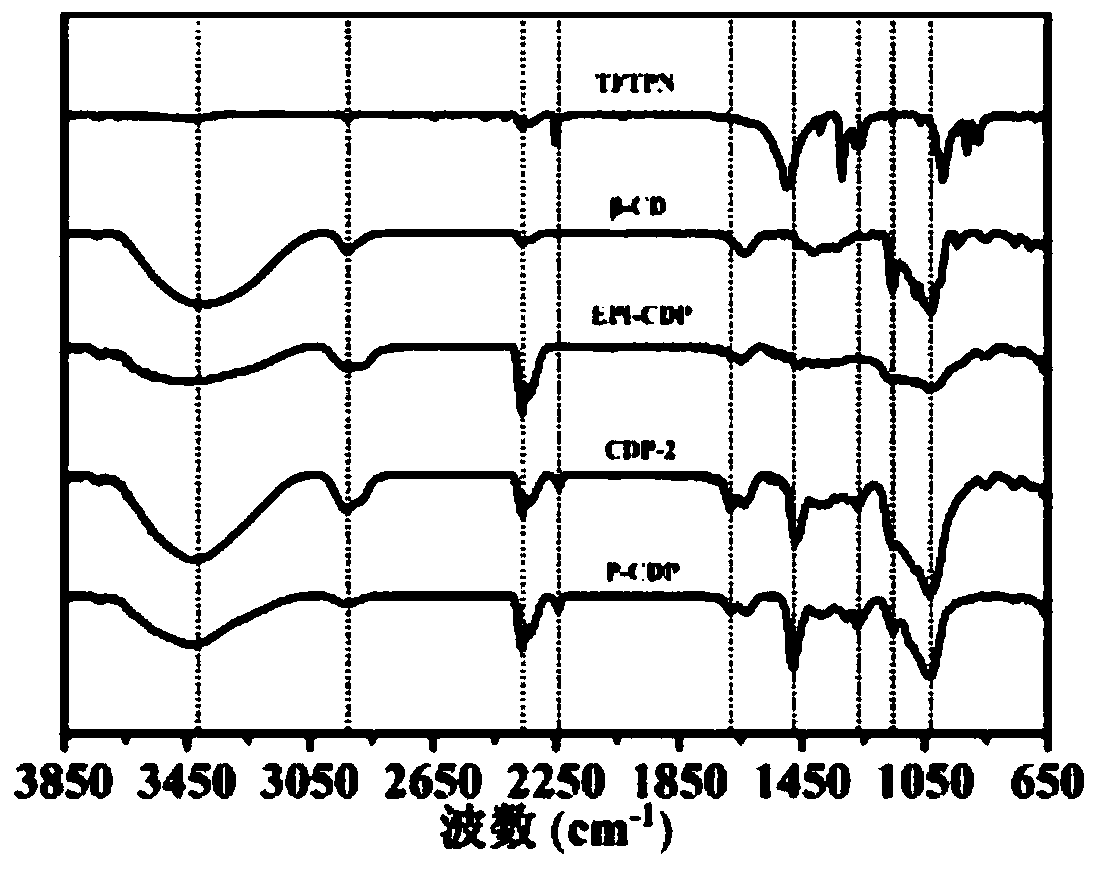

[0058] In order to better understand the present invention, a variety of cyclodextrin polymers were prepared under different conditions (such as cyclodextrin type, rigid cross-linking agent and flexible cross-linking agent type and addition, alkali solution type and concentration, etc.) , and characterize its adsorption effect to various organic micro-pollutants in the aqueous solution, the specific conditions of each embodiment are shown in Table 1. In order to illustrate the adsorption effect of the cyclodextrin polymer prepared by the present invention, two different cyclodextrin polymers were prepared as comparative examples for comparison with reference to the literature. Among them, comparative example 1 prepares a cyclodextrin polymer (EPI-CDP), which is the most researched in the field of adsorption, is also the most mature and has been commercialized. The polymer has a non-porous structure and a very low specific surface area. Comparative Example 2 prepared a recentl...

Embodiment 2

[0120] Example 2, Examples 5-8 prepared cyclodextrin polymers using different rigid crosslinking agents. These rigid crosslinkers include: decafluorobiphenyl, tetrafluoroterephthalonitrile, decafluorobenzophenone, and octafluoronaphthalene, and combinations thereof. Figure 13The adsorption rates of BPA on cyclodextrin polymers prepared by different rigid crosslinking agents are given, and it can be seen that regardless of the single Both of them, or their combination, can be used as rigid crosslinking agent to prepare cyclodextrin polymer with fast adsorption rate, among which tetrafluoroterephthalonitrile and decafluorobenzophenone are the best. Cyclodextrin polymers prepared with different rigid cross-linking agents will have different adsorption properties due to the difference in cross-linking degree and pore structure. The above results indicate that the rigid cross-linking agent containing benzene ring structure mainly acts as a rigid scaffold, enabling the formation o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com