An integrated abrasive belt tool for grinding, polishing and measuring

A technology of abrasive belts and tools, which is applied in the field of precision free-form surface grinding and polishing, can solve problems such as lack of precision fixed-point modification capabilities, and achieve the effects of improving service life, improving processing efficiency, and fast and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

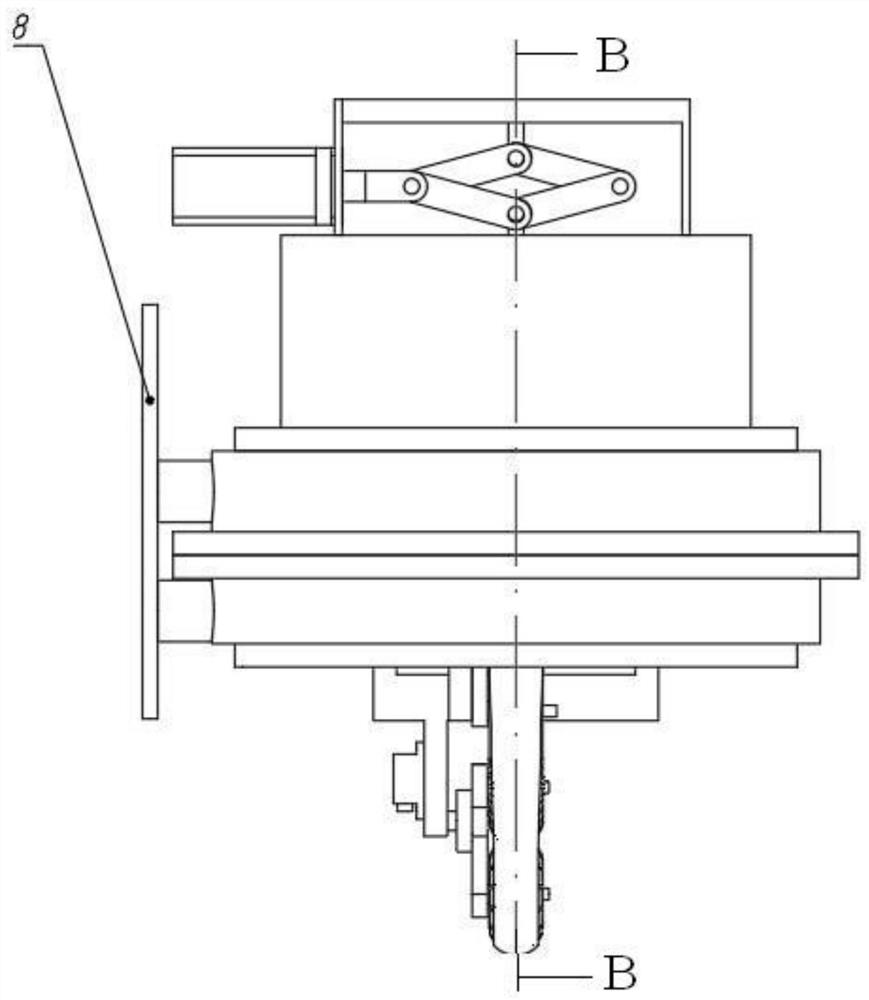

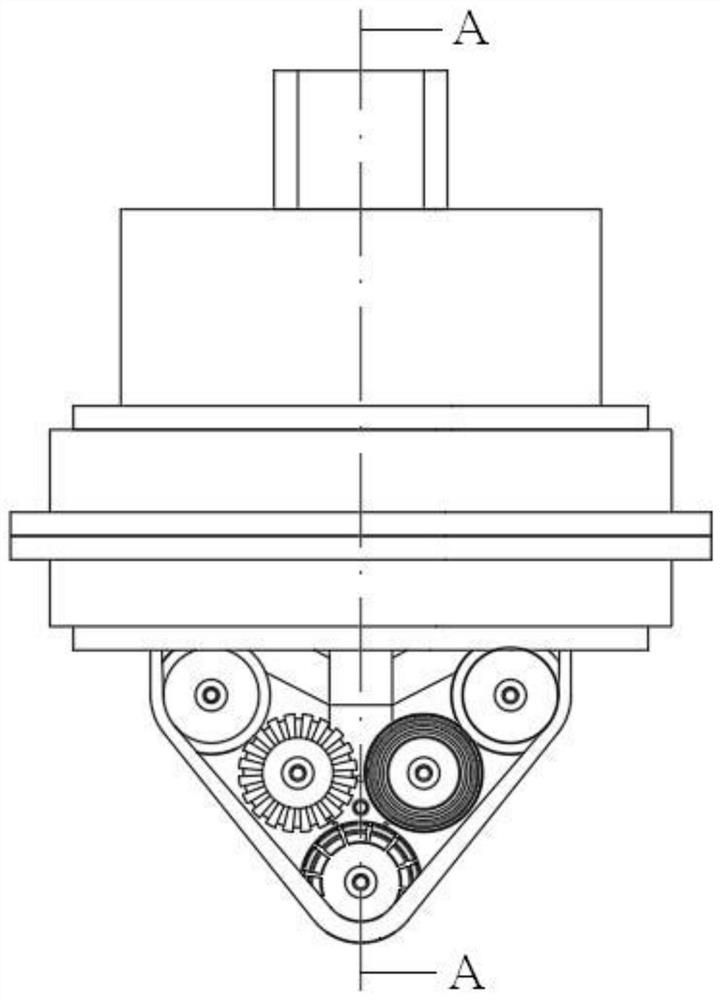

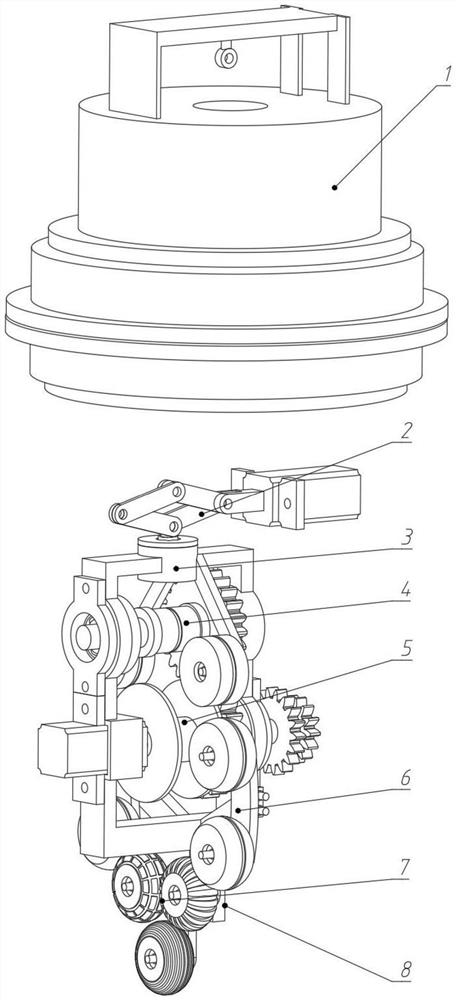

[0042] Such as Figure 1a , Figure 1b , figure 2As shown, it includes: housing unit 1, connecting rod lifting unit 2, revolution support unit 3, rotation drive unit 4, revolution drive unit 5, abrasive belt guide wheel unit 6, contact wheel unit 7, and laser range finder 8, among which The connecting rod lifting unit 2 is fixed on the upper part of the housing 1, the revolution supporting unit 3 is fixed below the connecting rod lifting unit 2, the rotation driving unit 4 is fixed on the upper part of the revolution supporting unit 3, and the revolution driving unit 5 is fixed on the lower part of the revolution supporting unit 3. The belt guide wheel unit 6 is fixed on the revolution support unit 3 , and the contact wheel unit 7 and the laser range finder 8 are fixed on the lower part of the revolution support unit 3 .

[0043] Such as Figure 3a As shown, the housing unit 1 includes a connecting rod housing 101, a main housing 102, a first ring gear housing 103 and a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com