Automatic welding device for manhole door of wind power generation tower barrel

An automatic welding and manhole door technology, applied in auxiliary devices, welding equipment, manufacturing tools, etc., can solve the problems of high production and manufacturing cost, low production efficiency, low degree of automation, etc., to reduce production costs, improve welding efficiency, The effect of strong structural reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to illustrate the technical solution of the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings. Obviously, the accompanying drawings described below are only an embodiment of the present invention. For those of ordinary skill in the art, On the premise of not paying creative work, other embodiments obtained according to the drawings and embodiments all belong to the protection scope of the present invention.

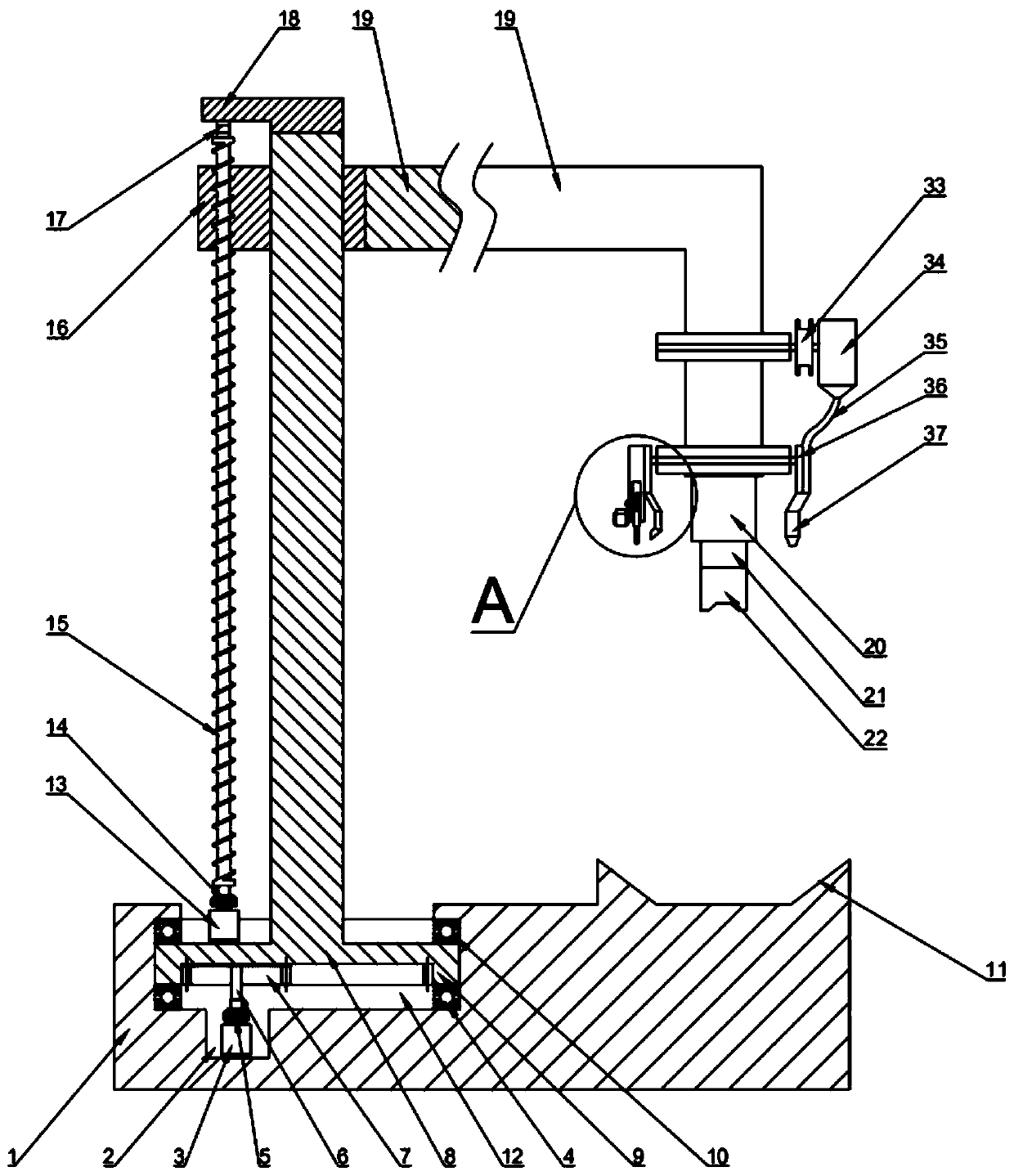

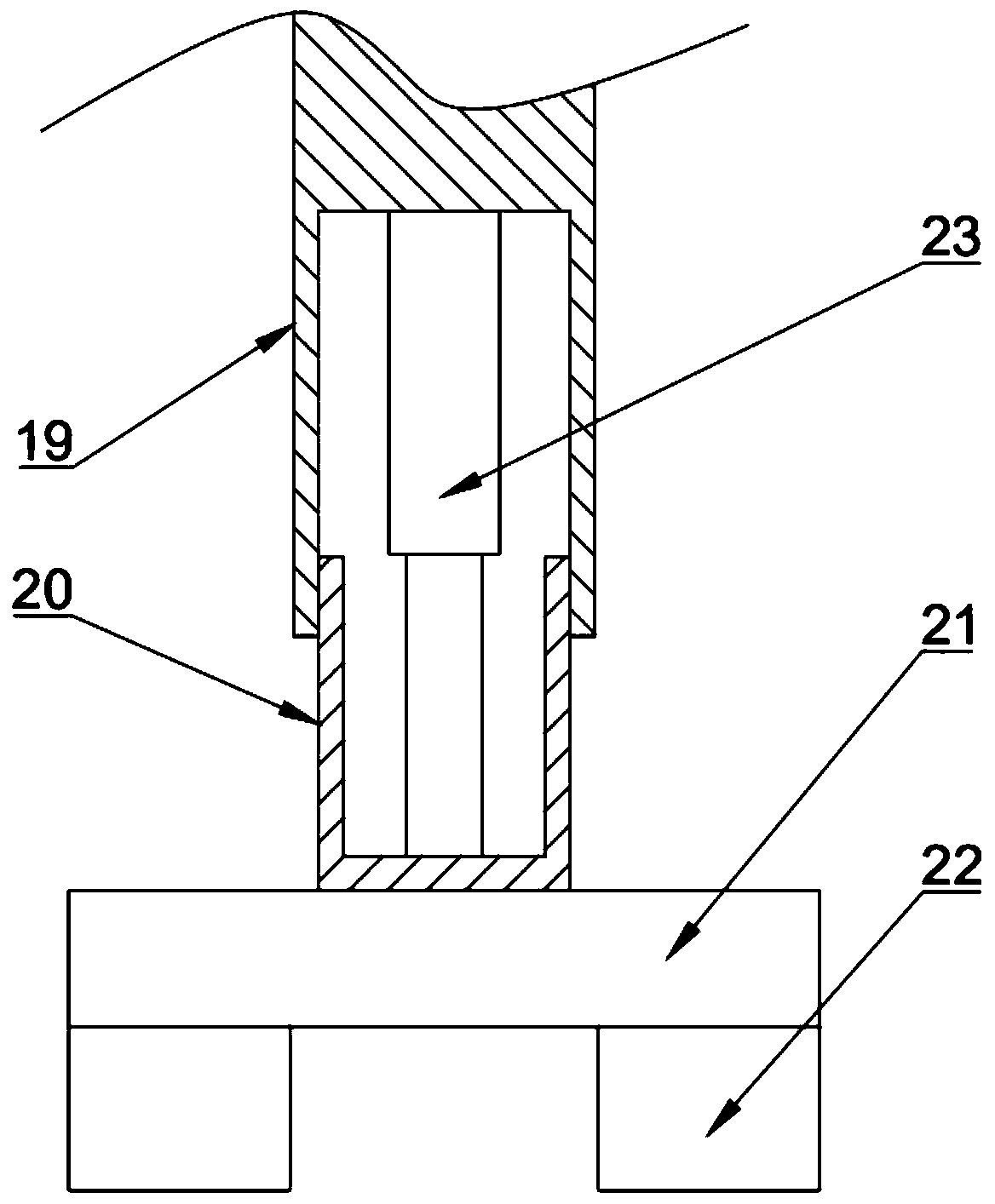

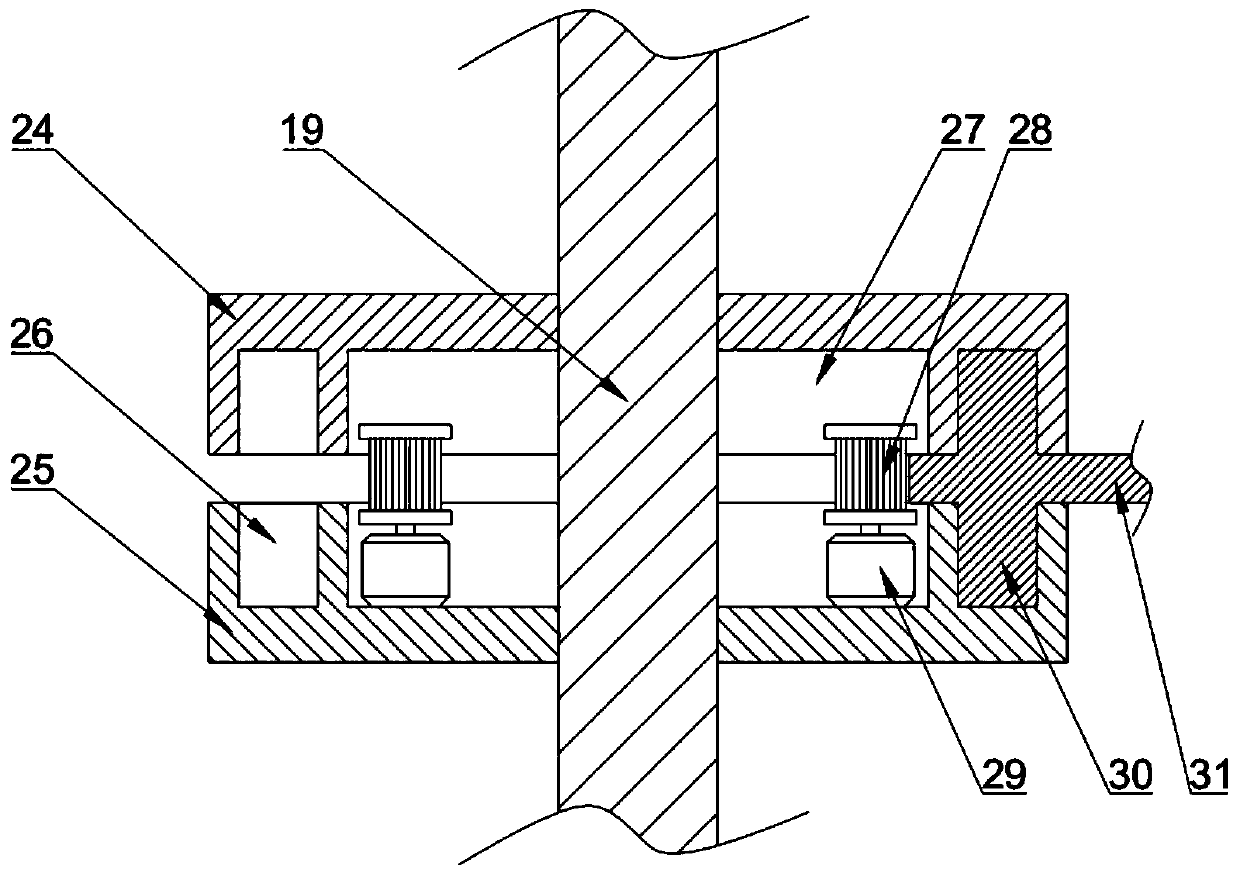

[0018]An automatic welding device for a manhole door of a wind power generation tower, including a base 1, tower claws 11, a complete machine rotation mechanism, a working arm lifting mechanism, and an automatic welding mechanism. The complete machine rotation mechanism includes a rotary drive motor installation groove 2 , rotary drive motor 3, bottom bearing 4, harmonic reducer 5, rotary drive shaft 6, drive gear 7, lifting guide column 8, ring gear 9, top bearing 10, rotary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com