Overhead pipeline paint spraying walking device and overhead pipeline paint spraying method

A technology of overhead pipelines and running devices, applied in the direction of spraying devices, can solve the problems of high risk, slow coating speed, slow spraying speed, etc., and achieve the effects of high spraying efficiency, reduction of erection, and improvement of adsorption force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

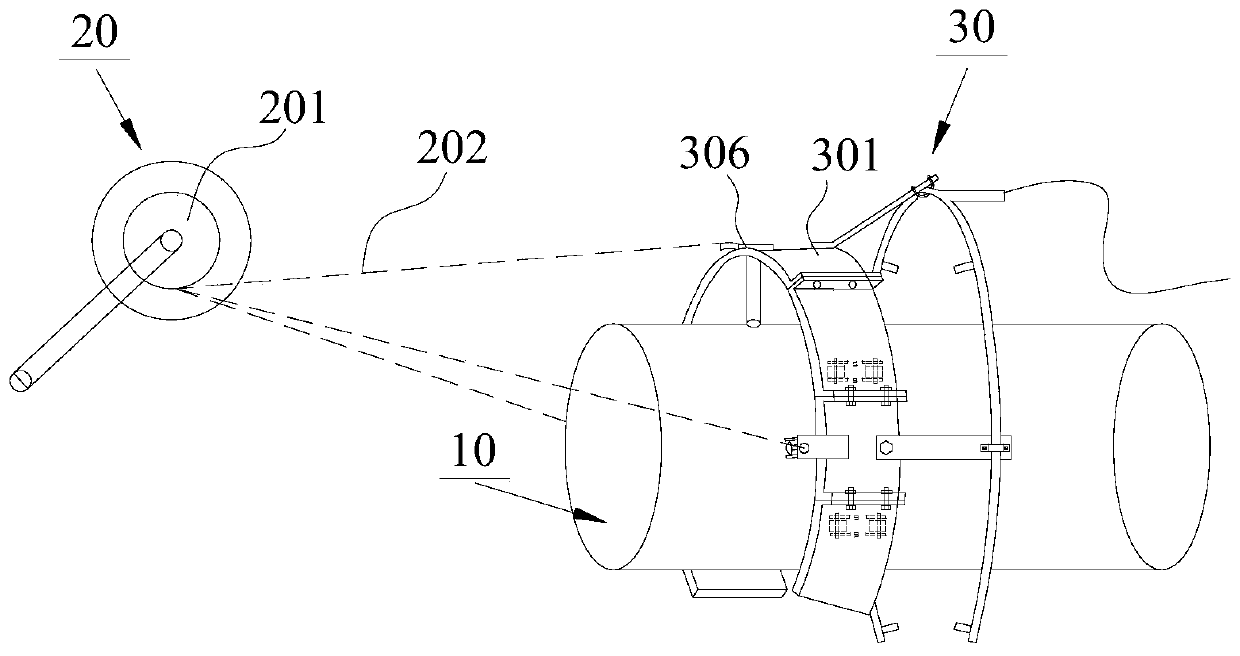

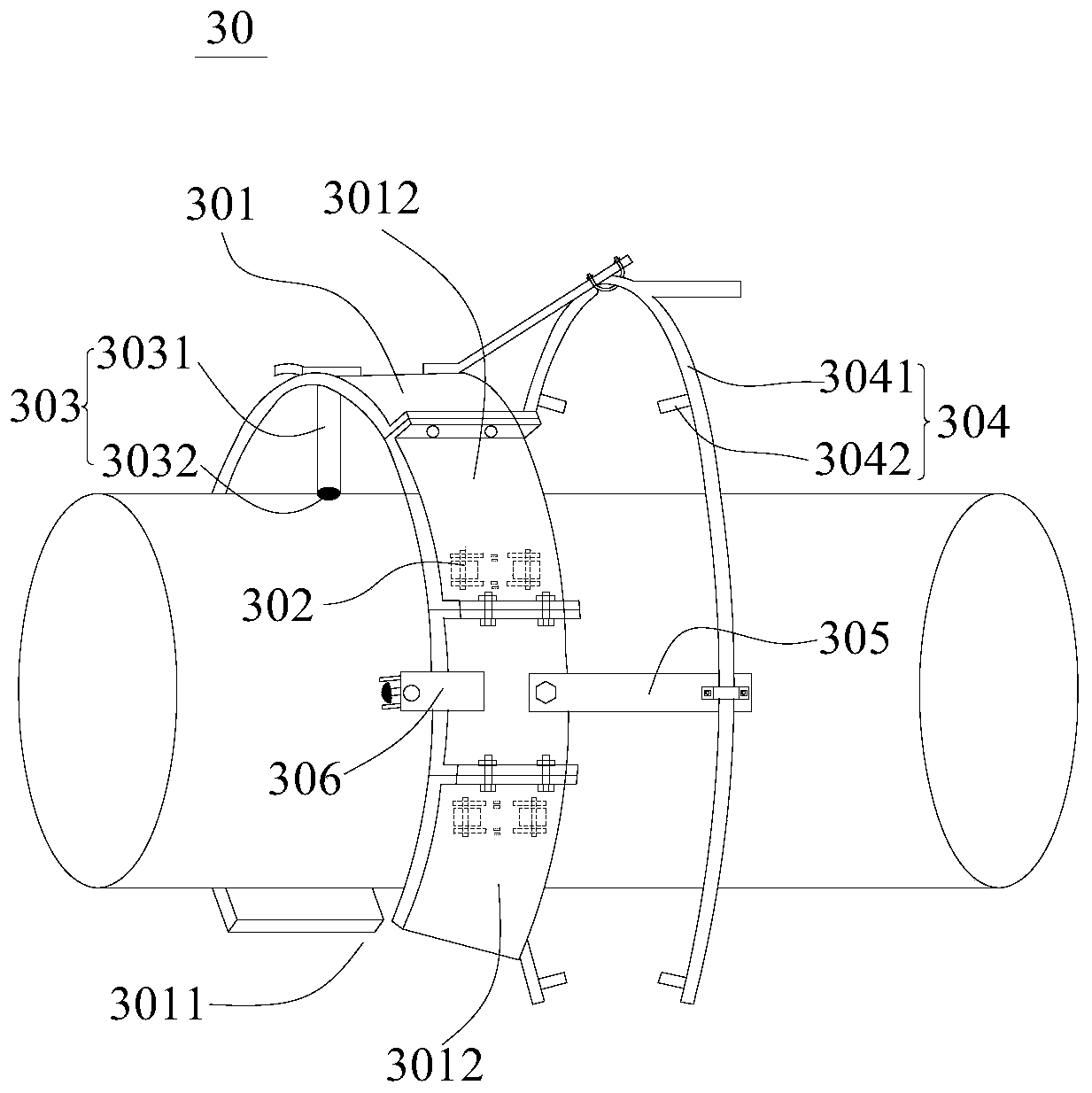

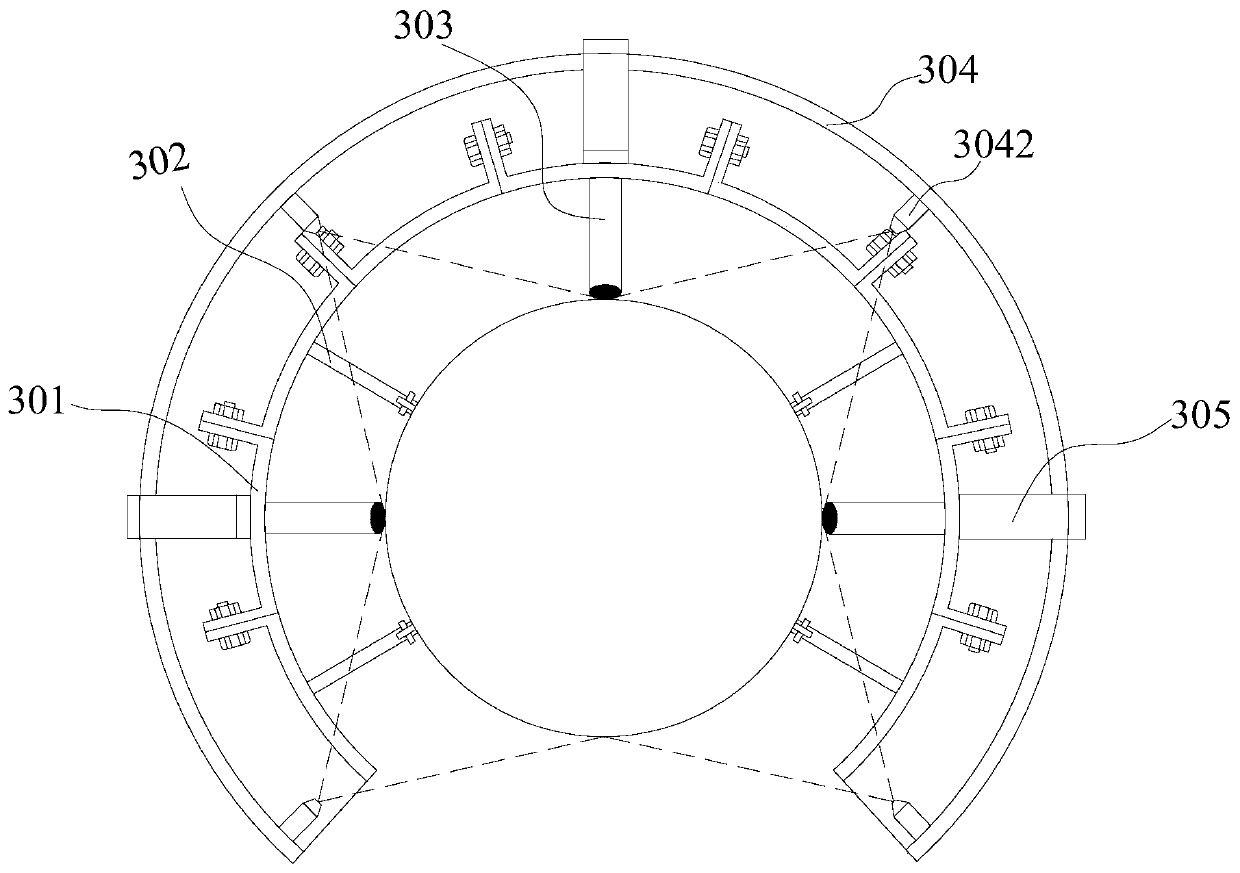

[0043] like Figures 1 to 5 As shown, the overhead pipeline spraying running device of this embodiment is applied to the overhead pipeline 10, wherein the overhead pipeline 10 is made of metal iron. The spraying traveling device 30 of the overhead pipeline 10 includes an annular support 301 , a traveling assembly 302 , a limiting assembly 303 and a spraying assembly 304 .

[0044] like figure 2 and 3 As shown, an annular support 301 is used to support a spray assembly 304 . The ring support 301 is provided with an opening 3011 for passing through the tube support of the overhead pipeline 10, so that the ring support 301 can smoothly pass through the support of the overhead pipeline when the ring support 301 moves axially around the pipeline 10. Specifically, the annular support 301 includes a plurality of connected arc-shaped plates 3012...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com