Mandibular implant and method of making same

A manufacturing method, mandible technology, applied in the direction of bone implants, prostheses, skulls, etc., can solve the problem that the negative type of the scaffold does not have the internal structure and mechanical properties, the growth factors and bone cells are not easy to attach, and the internal microstructure is easy to improve the survival rate of bone, increase the attachment surface area, and facilitate attachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

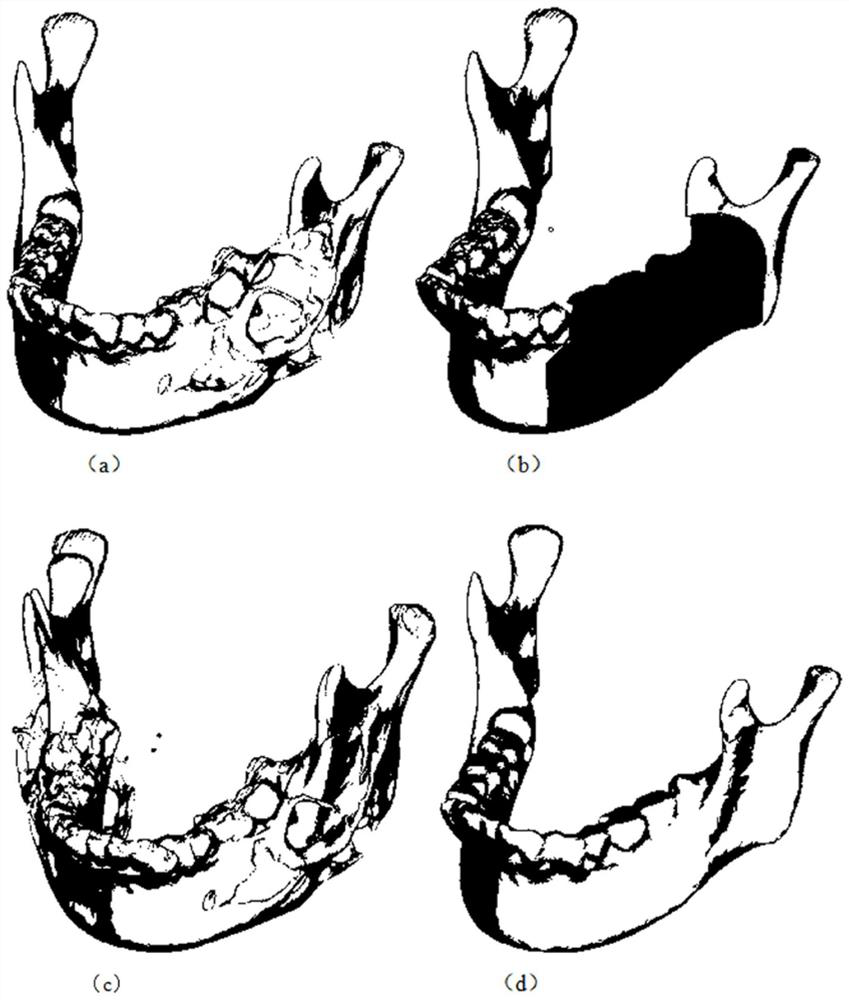

[0033] refer to Figure 1~3 , a mandibular implant and a manufacturing method thereof, comprising the following steps:

[0034] 1) Negative design and fabrication of bracket

[0035] 1.1 Use the image-based 3D reconstruction technology to reconstruct the 3D model of the bone defect through CT data, and then obtain the repair model through the mirror image algorithm or the surface design method. The shape of the defect part separated from the repair model is the mandibular implant. body shape model;

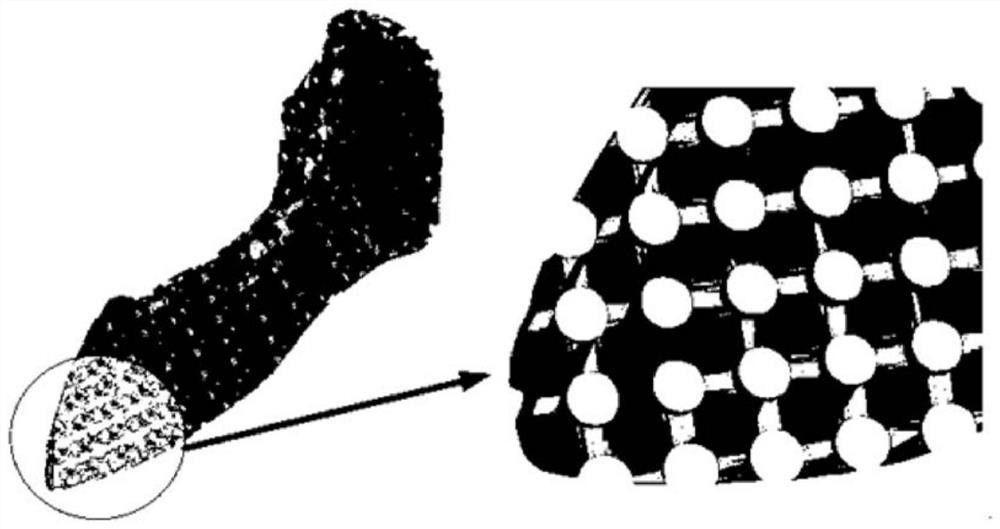

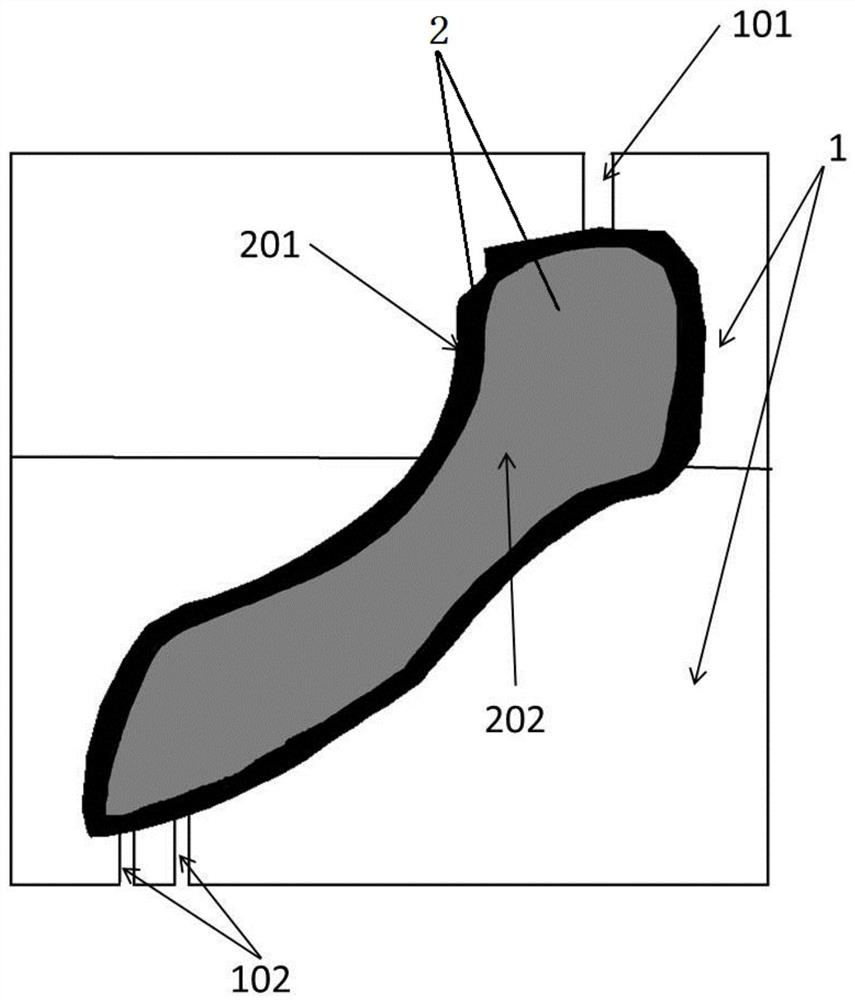

[0036] 1.2 Design a scaffold microstructure array with porosity and structural form, and the scaffold microstructure array is an internal microstructure with any full connectivity;

[0037] 1.3 Perform a Boolean subtraction operation on the shape model of the mandibular implant at the bone defect site and the microstructure array of the scaffold to obtain a ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com