Color nano printing device based on micro-nano polarizer and F-P cavity structure

A color printing, F-P technology, used in polarizing elements, instruments, optical elements, etc., can solve problems such as long distances, and achieve the effect of easy integration, small size, and flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

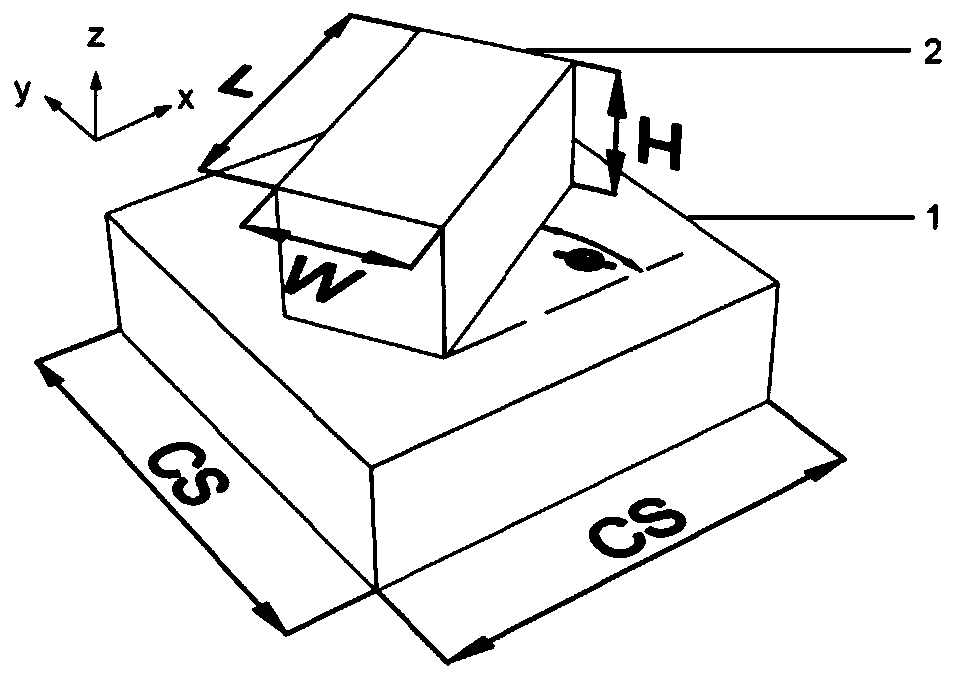

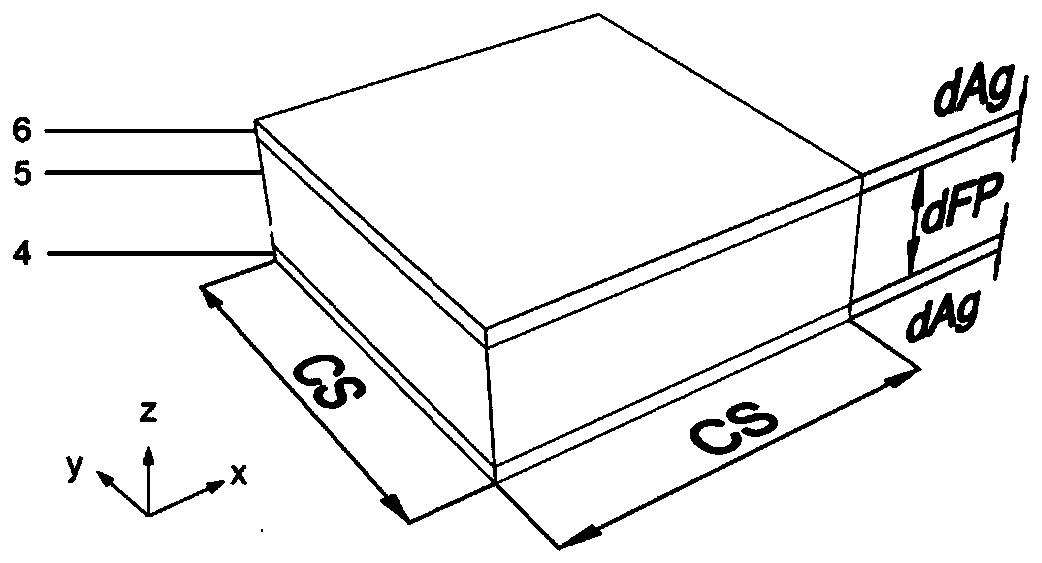

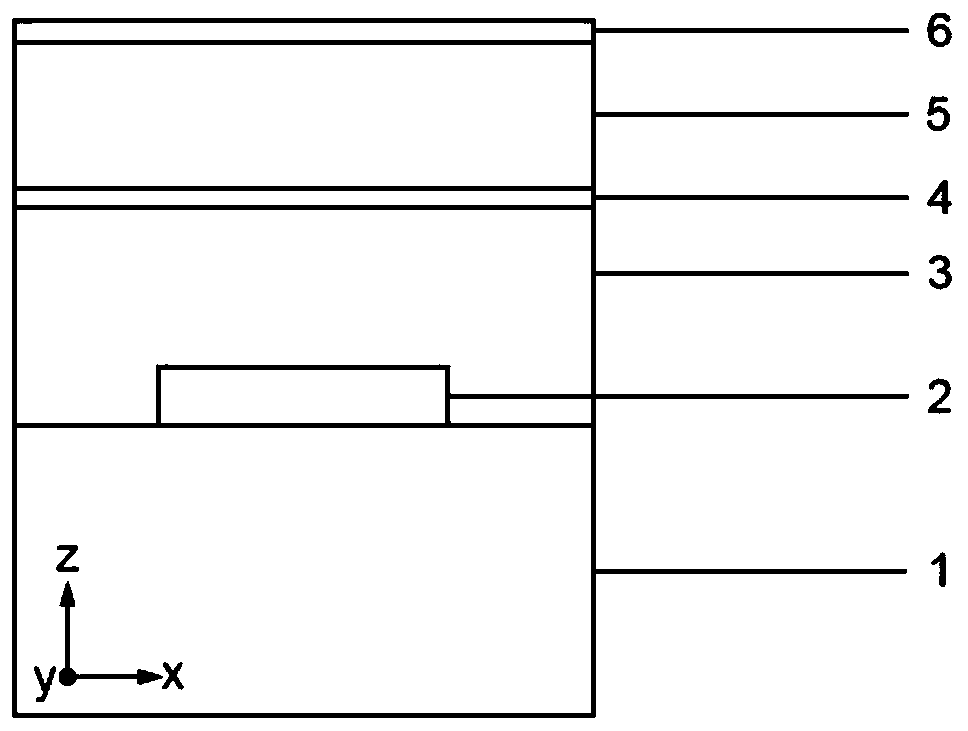

[0041] In this embodiment, the stacked metasurface based on metal nano bricks and micro-nano F-P cavity is applied to color nano-printing technology. The metal nano-brick array is composed of a substrate and a metal nano-brick array. Through the design, polarization separation (transmitted light) in a specific broadband wavelength range can be realized; the micro-nano F-P cavity is composed of the upper and lower silver layers and the thickness of the middle dielectric layer. , the response of different wavelengths can be achieved by adjusting the thickness of the intermediate dielectric layer, while the thickness of the upper and lower silver layers can be used to control the narrow bandwidth and peak efficiency of the transmission spectrum; the structure of the metal nanobrick and the micro-nano F-P cavity is implemented by the inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com