A method, device and electronic equipment for obtaining the thickness of oxide film layer of composite material

A composite material and oxide film technology, applied in measuring devices, complex mathematical operations, instruments, etc., can solve the problems of large material differences, rapid ablation, time-consuming and labor-intensive problems, and achieve low cost, improved accuracy, and accurate measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

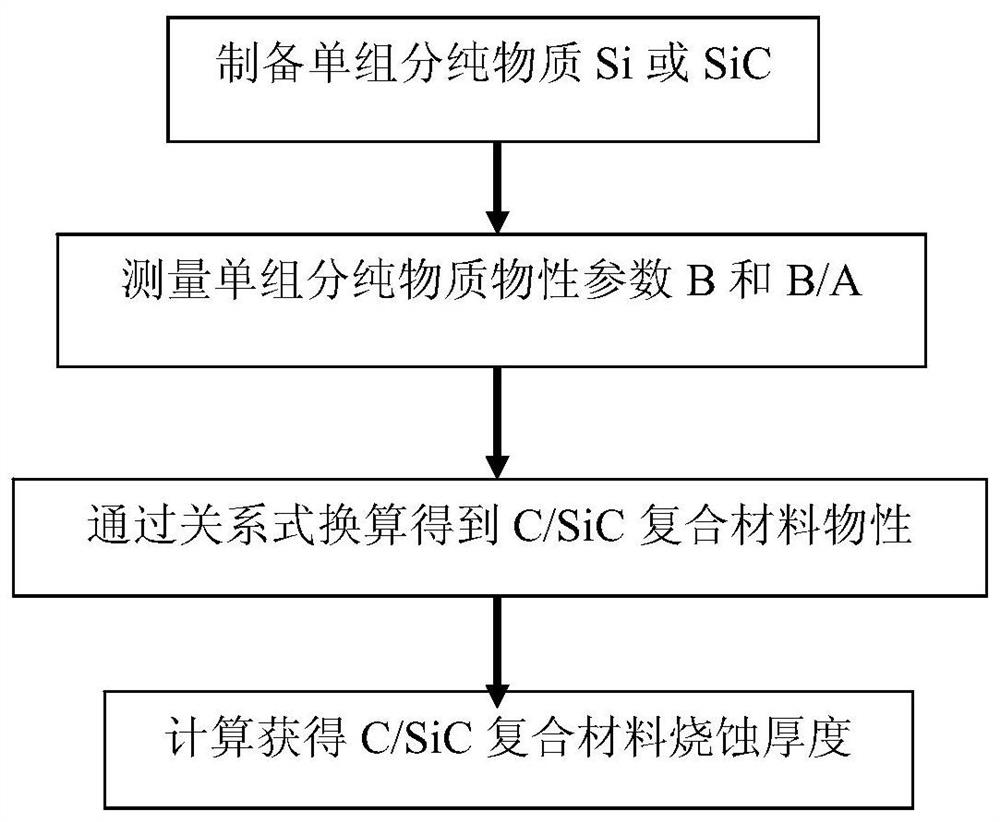

[0091] Such as figure 1 Shown is the flow chart of the method for obtaining the thickness of the oxide film layer of the composite material in the present invention. The method for obtaining the thickness of the oxide film layer of the composite material in the present invention specifically includes the following steps. The composite material C / SiC is taken as an example below:

[0092] (1) Determine the inert oxidation reaction process and reaction equation of C / SiC composites. Inert oxidation refers to the formation of a layer of SiO on the surface of C / SiC 2 Protective film, oxygen must diffuse through the oxide film to reach C / SiC and react with it, the interface reaction equation is

[0093]

[0094]

[0095] The inert oxidation process includes the following processes:

[0096] 1) Oxygen diffuses to SiO through the boundary layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com