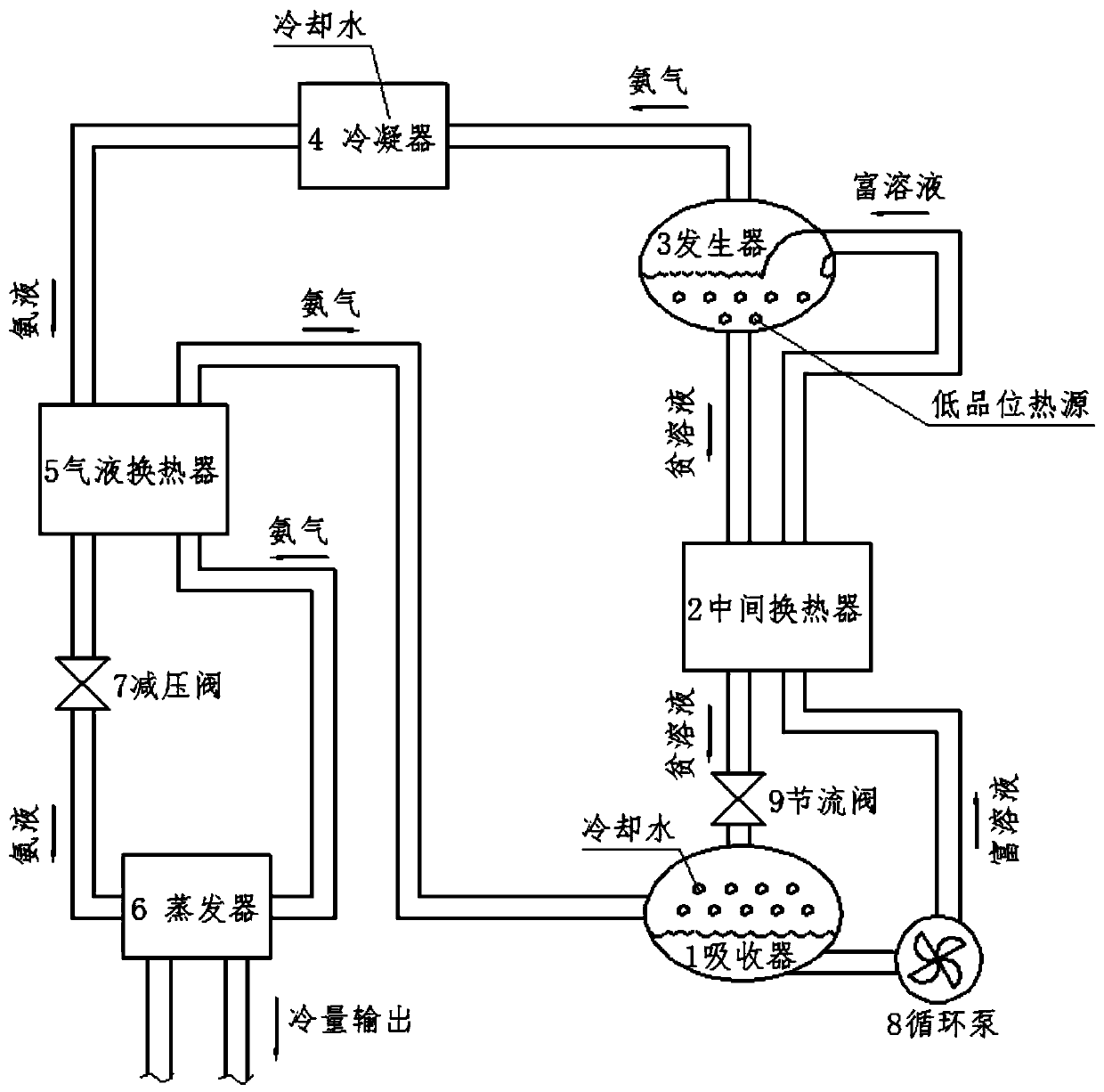

Three-phase heat exchanger and absorption type refrigeration system comprising same

An absorption refrigeration and heat exchanger technology, applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger type, etc., can solve the problems of unsuitable absorption refrigeration system, difficult processing, complicated design, etc. Improve energy utilization efficiency, compact structure, and reduce the effect of heat source heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

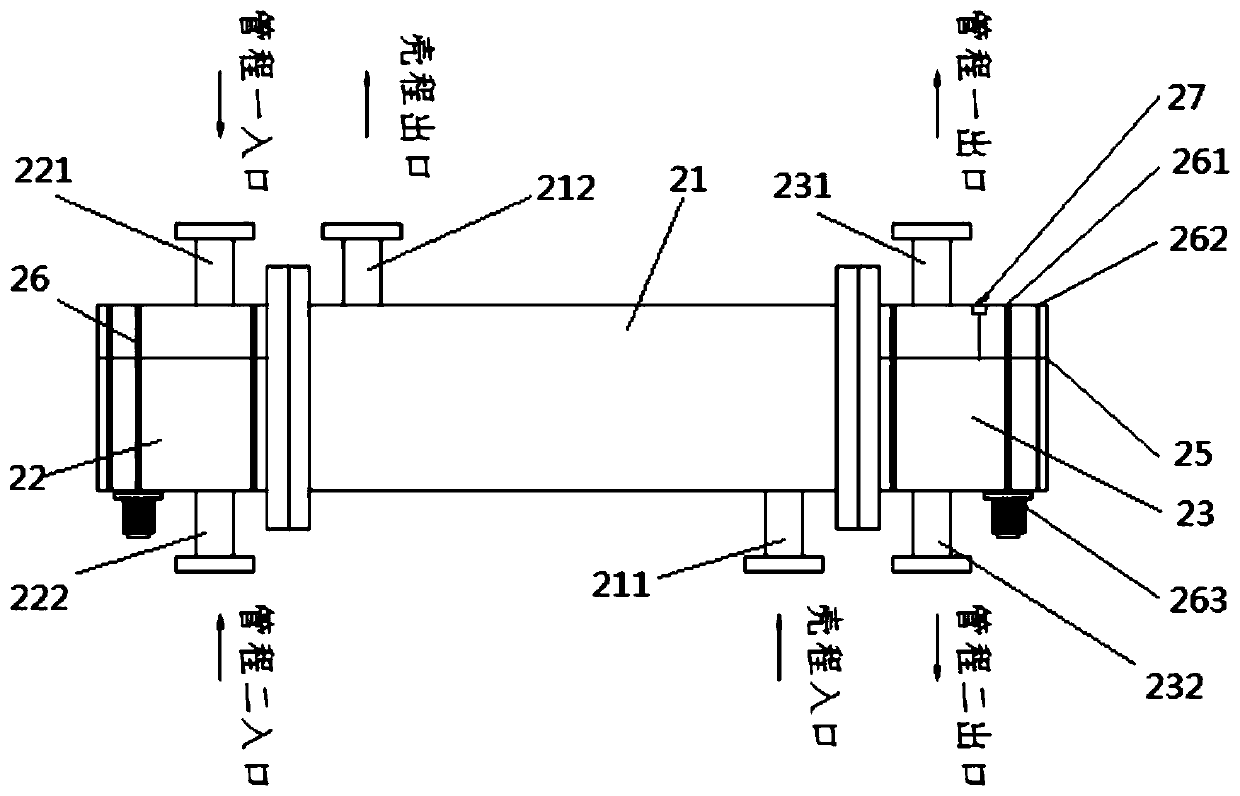

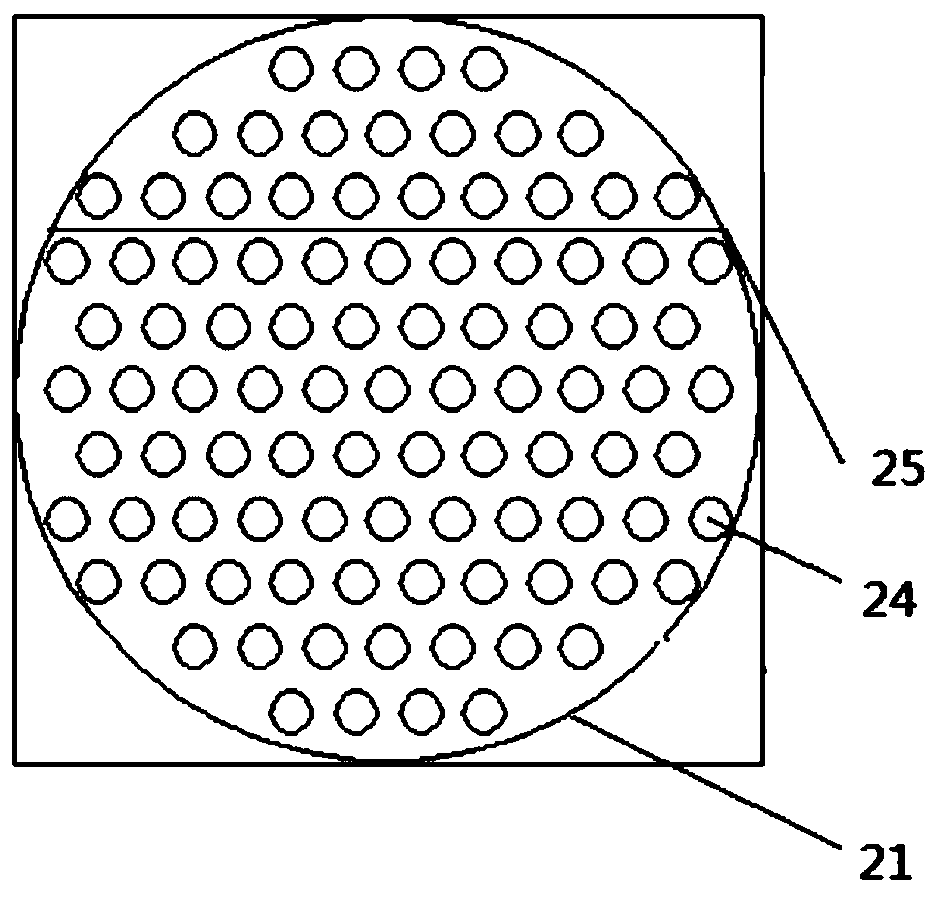

[0028] This embodiment provides a three-phase heat exchanger 2, such as Figure 2-3 As shown, the shell-side cylinder 21 is included, the shell-side cylinder 21 is provided with a plurality of shell-and-tube heat exchange tubes 24, and the two ends of the shell-side cylinder 21 are respectively provided with a first tube-side cylinder 22 and the second tube-side cylinder 23, the first tube-side cylinder 22 and the second tube-side cylinder 23 communicate through the heat exchange tube 24, and the shell-side cylinder 21 is provided with a shell-side inlet 211, a shell-side The outlet 212, the shell-side inlets and outlets 211, 212 communicate with the heat exchange tube 24 to form a shell-side passage, and the first tube-side cylinder 22 is provided with two tube-side inlets, which are respectively the first tube-side inlet 221 and the second tube-side inlet Inlet 222, the second tube pass cylinder 23 is provided with two tube pass outlets, which are respectively the first tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com