Explosion-proof door of waste heat boiler

A waste heat boiler and explosion-proof door technology, which is applied to the components of steam boilers, steam boilers, steam boiler accessories, etc., can solve the problems of frequent jumping and difficult reset of explosion-proof doors, and achieve the effect of avoiding frequent jumping and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

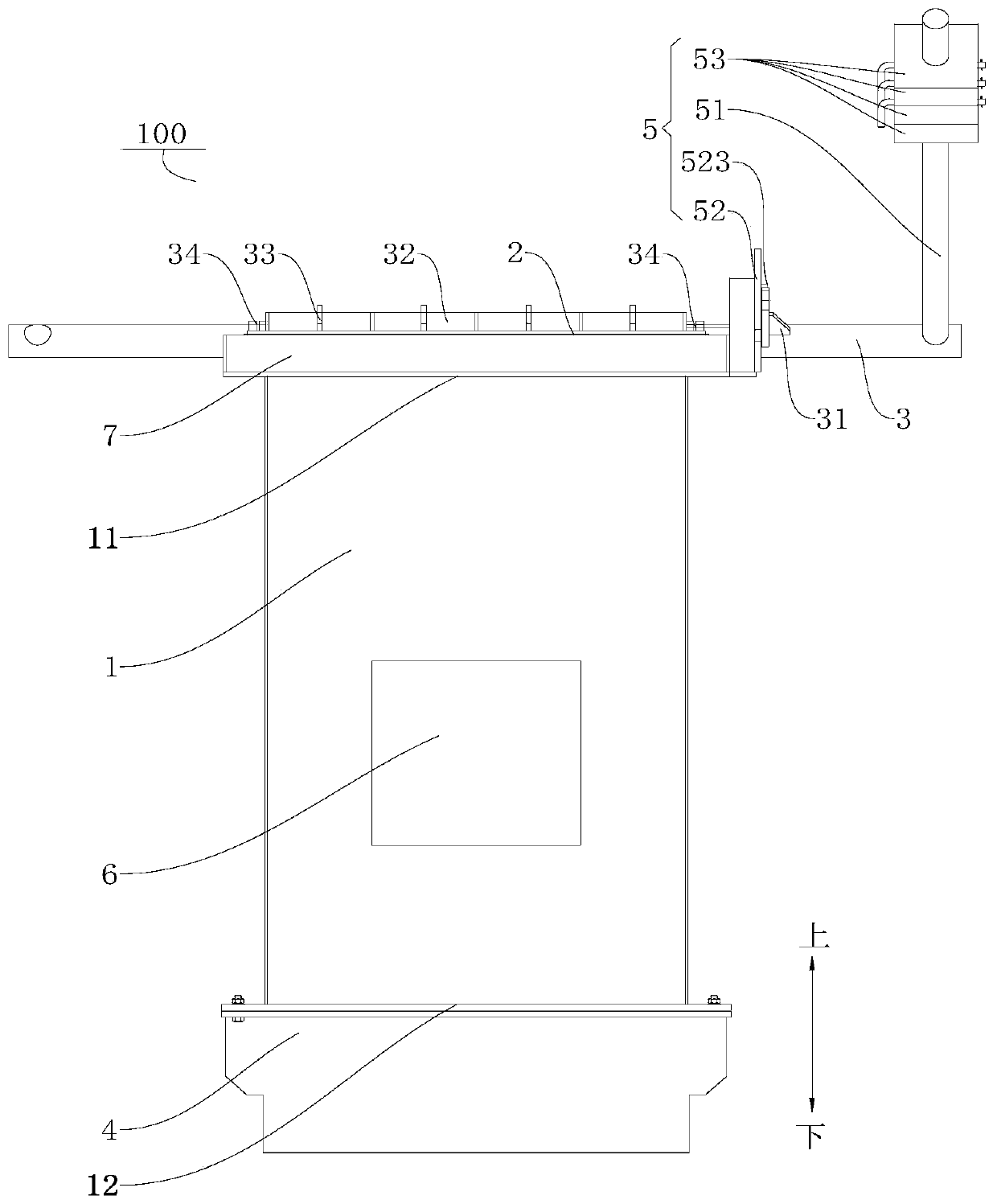

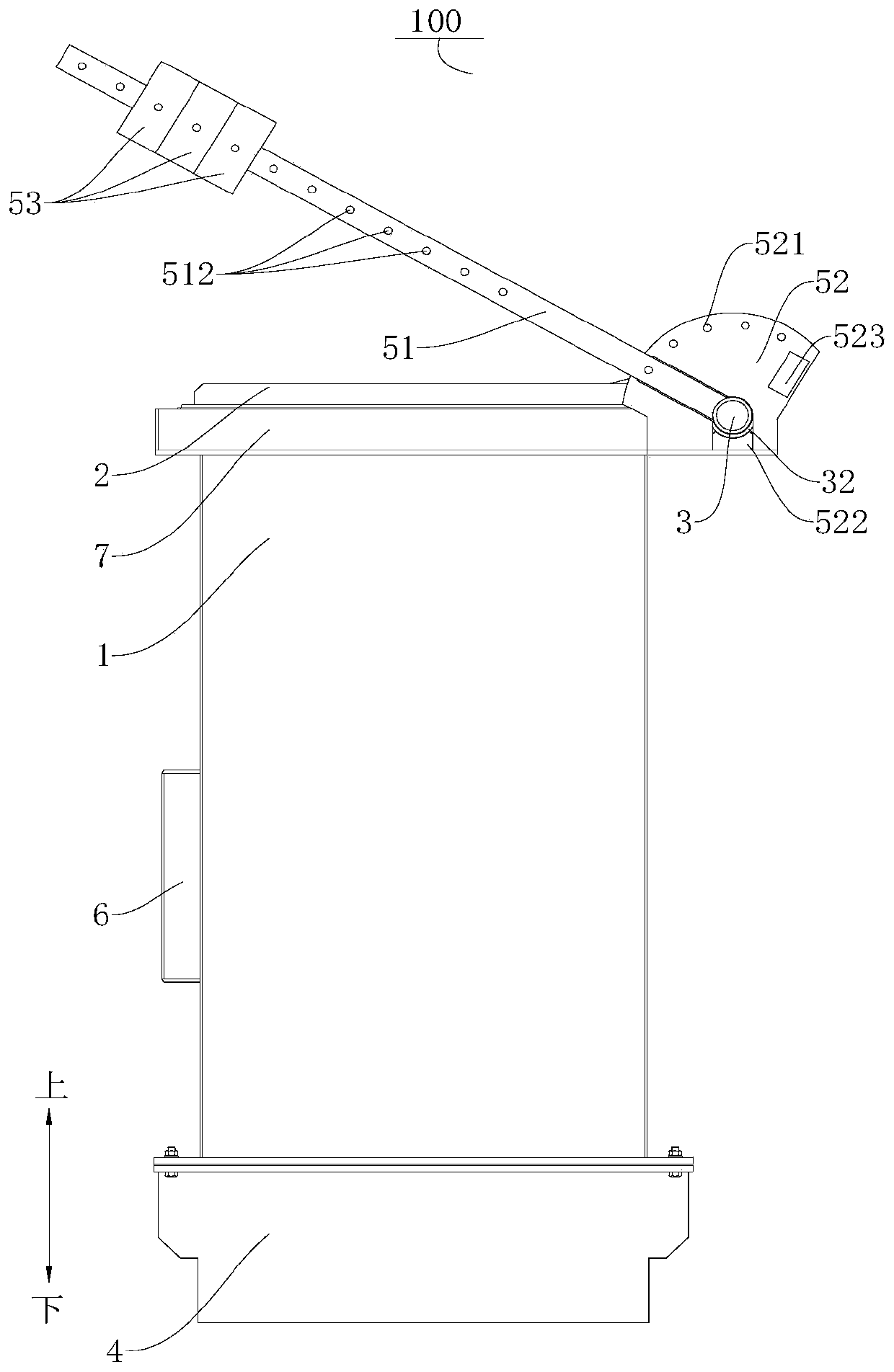

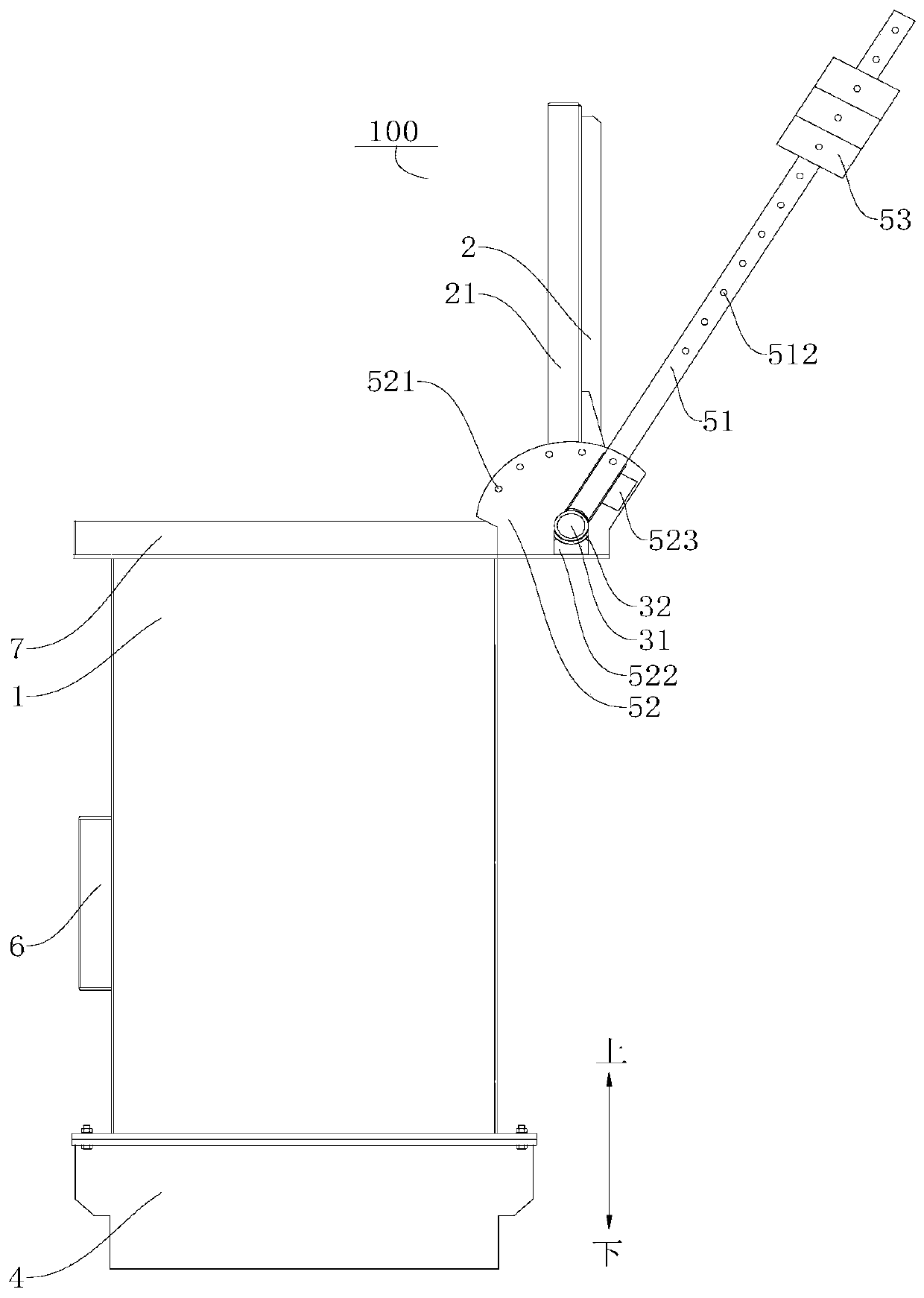

[0070] An explosion-proof door 100 of a waste heat boiler includes: an explosion-proof door connector 1, an explosion-proof door cover 2, a rotating shaft 3, a cooling element 4, a limiting component 5, a transparent observation port 6 and an annular sealing groove 7.

[0071] Such as Figure 4 with Figure 7 As shown, the explosion-proof door connector 1 is in a vertical cylindrical shape. The top end of the explosion-proof door connector 1 is formed as an outlet 11, and the bottom end is formed as an inlet 12. An annular sealing groove 7 is provided around the outlet 11, and a seal is provided in the annular sealing groove 7 Sand like image 3 As shown, the explosion-proof door cover 2 is provided with a joint edge 21 that cooperates with the annular sealing groove 7. When the explosion-proof door cover 2 is closed on the outlet 11, the joint edge 21 is buried in the sealing sand. The cooling element 4 is formed as a water-cooled tube, and the water-cooling tube is arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com