Methanol injector

A technology of injectors and methanol, which is applied in the direction of fuel injection devices, machines/engines, engine components, etc., can solve the problems of large fluctuations in opening and closing response time, large fluctuations in oil volume, small spring preload, etc., and achieve reduction The effect of production cost, reduction of magnetic flux area, and increase of magnetic induction intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Structure of the present invention, further concrete description is as follows in conjunction with accompanying drawing:

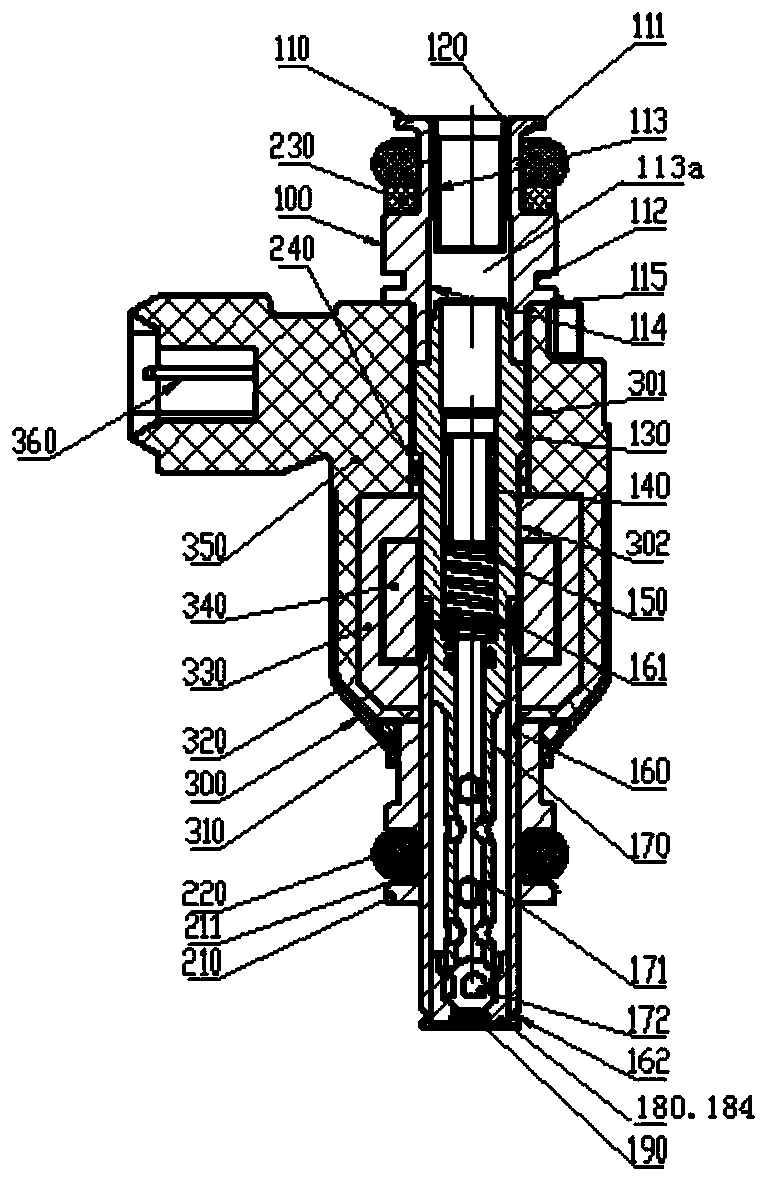

[0036] see Figure 1 to Figure 5 , the methanol injector shown in the figure includes a nozzle part 100 , a sealing part 200 and an electromagnet part 300 .

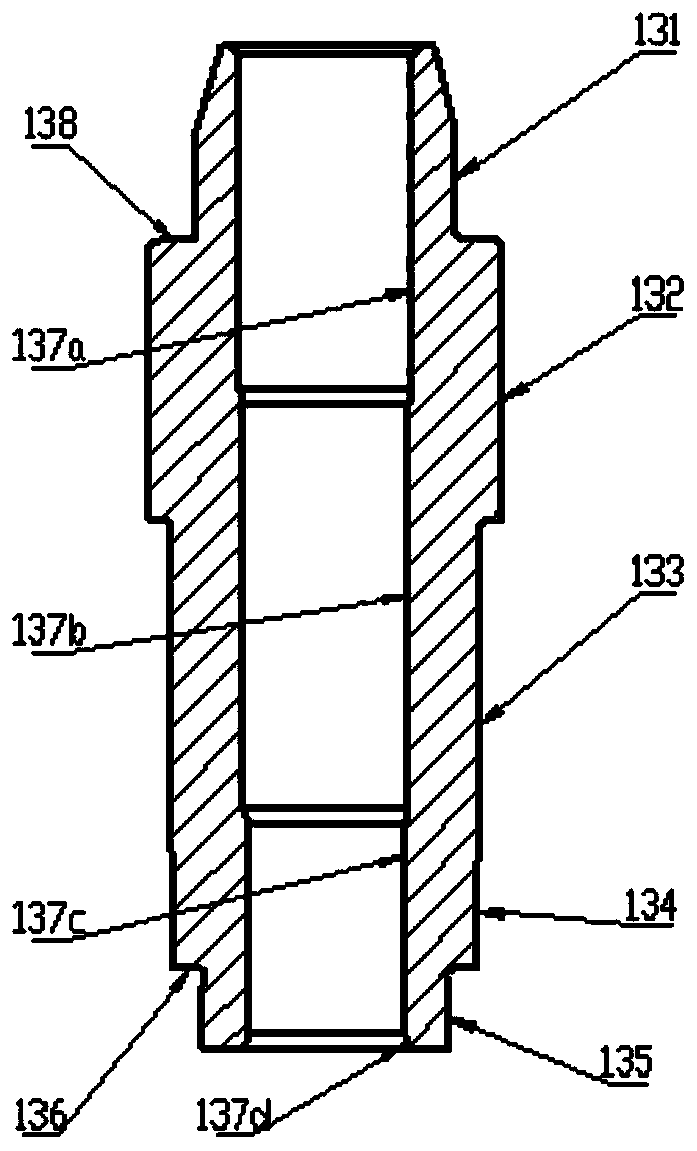

[0037] The nozzle component 100 mainly includes a nozzle plate 190 , a nozzle body 160 , a nozzle head 180 , a valve stem component 170 , a spring 150 , an iron core 130 , a spring upper seat 140 , a filter screen support 110 , and a filter screen 120 .

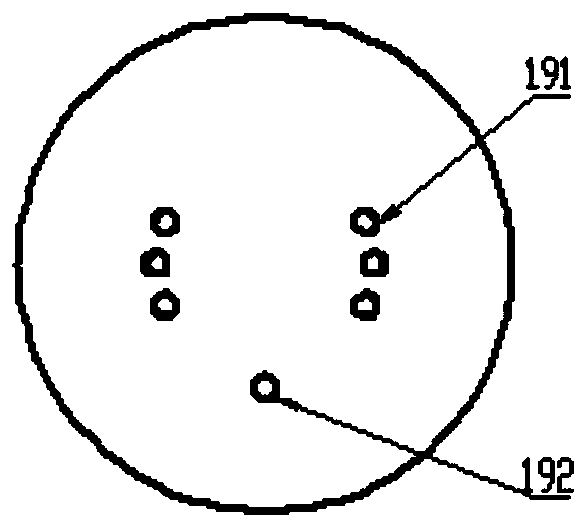

[0038] The nozzle plate 190 is provided with six spray holes 191 and one identification hole 192 . The nozzle holes 191 are through holes and distributed symmetrically along the nozzle plate 190 . The identification hole 192 is a blind hole, located on the symmetrical center line of the injection hole 191 .

[0039] The nozzle body 160 is a thin-walled cylindrical part. The nozzle body 160 is provided with two annular thin-walled ring groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com