Method for distinguishing coal spontaneous combustiondangerous zone by using goaf air leakage

A technology for dangerous areas and goafs, applied in mining equipment, mining equipment, earthwork drilling, etc., can solve the problems of wasting resources, increasing the blindness of fire area control, reducing the number of installations, improving the effect of air leakage detection, and facilitating The effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

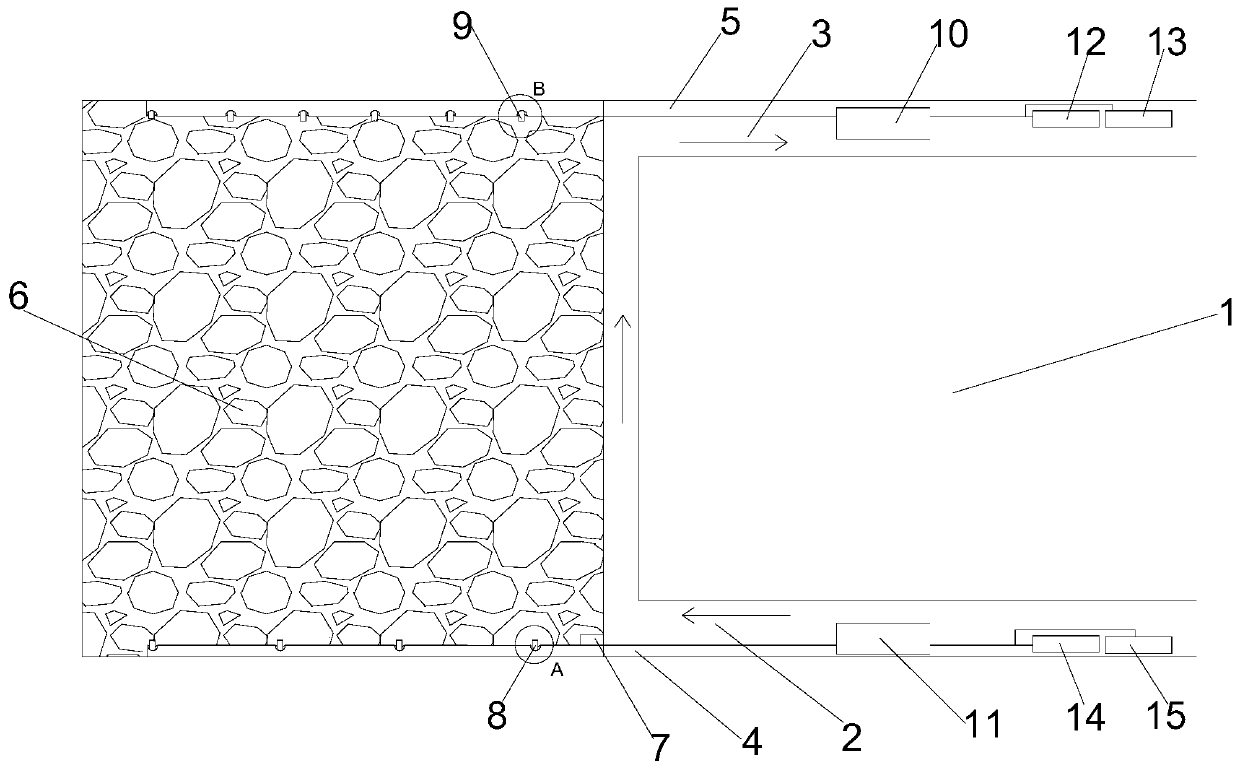

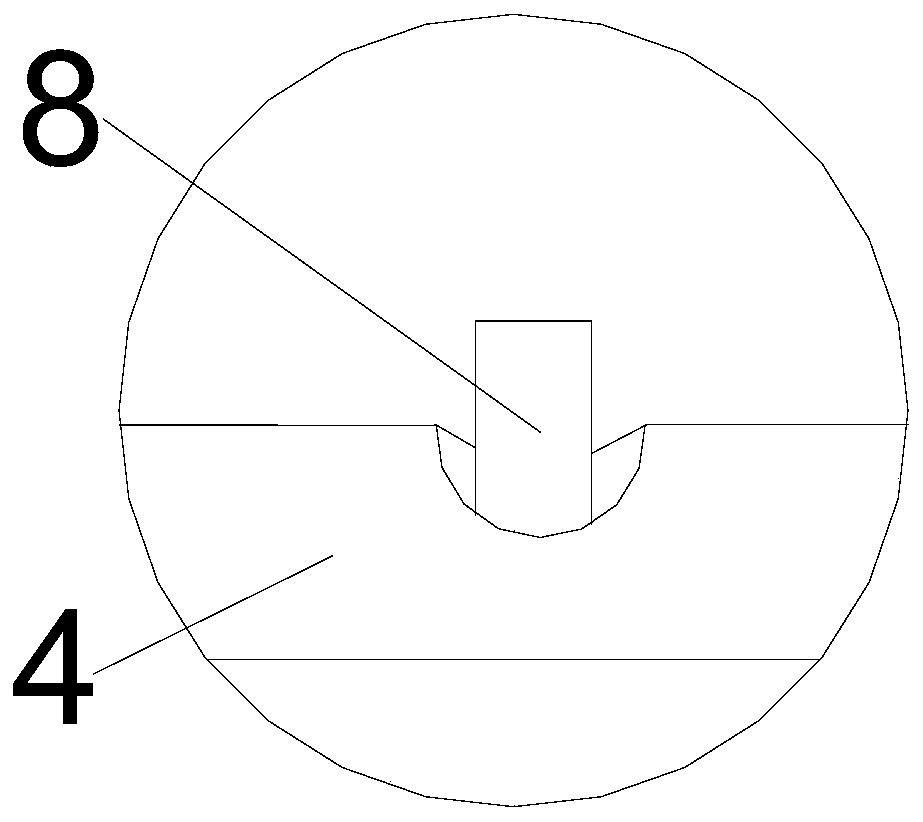

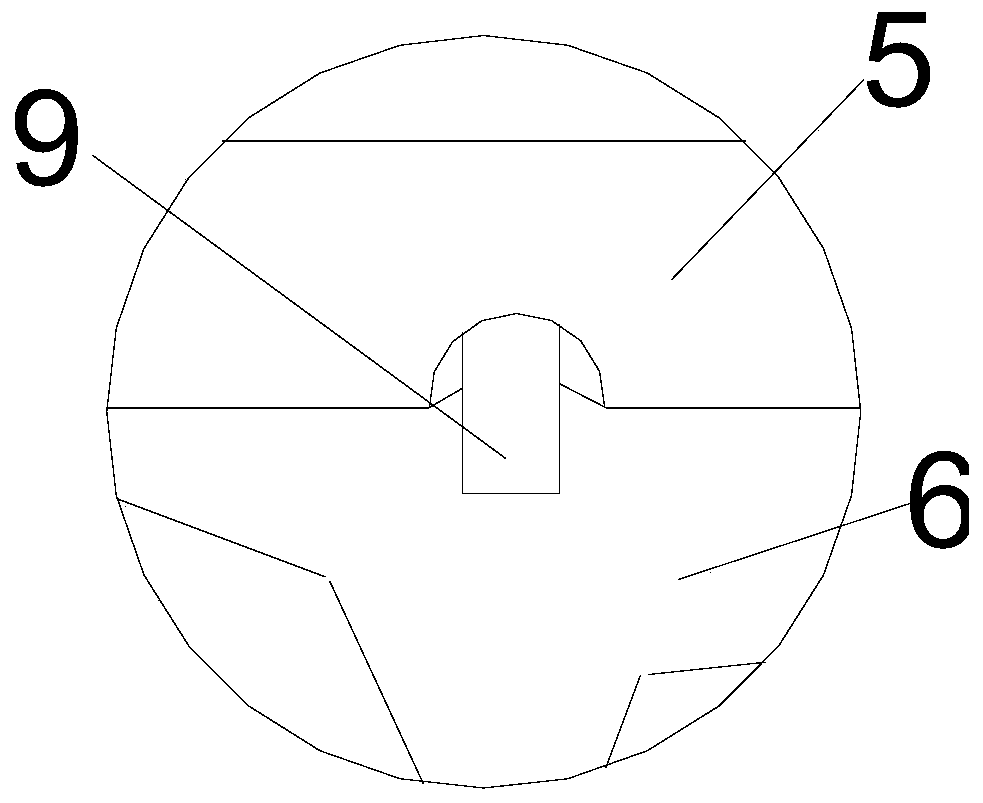

[0045] Such as Figures 1 to 5 As shown in the present invention, a method for discriminating coal spontaneous combustion dangerous areas by using goaf air leakage according to the present invention utilizes gob air leakage devices to monitor coal spontaneous combustion dangerous areas. The air inlet side sampling protection pipe 4 arranged near the side of the coal bank and the air return side sampling protection pipe 5 arranged along the side of the return air side trough 3 close to the coal side, the air inlet side sampling protection pipe 4 is far away from the air inlet side On the pipe section along the outlet of slot 2 and along its length direction, M monitoring ports 8 on the air inlet side are arranged, and on the pipe section along the outlet of slot 3 on the return air side, N monitoring ports are arranged along its length direction. The monitoring port 9 on the air return side, wherein M and N are both positive integers and M is less than N; the sampling protectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com