A coal-fired coupled biomass power generation system and method

A biomass power generation and biomass pyrolysis technology, which is applied in the direction of combustion method, biofuel, liquid hydrocarbon mixture preparation, etc., can solve the problems of poor adaptability of raw materials, low efficiency of coal-fired coupled biomass power generation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

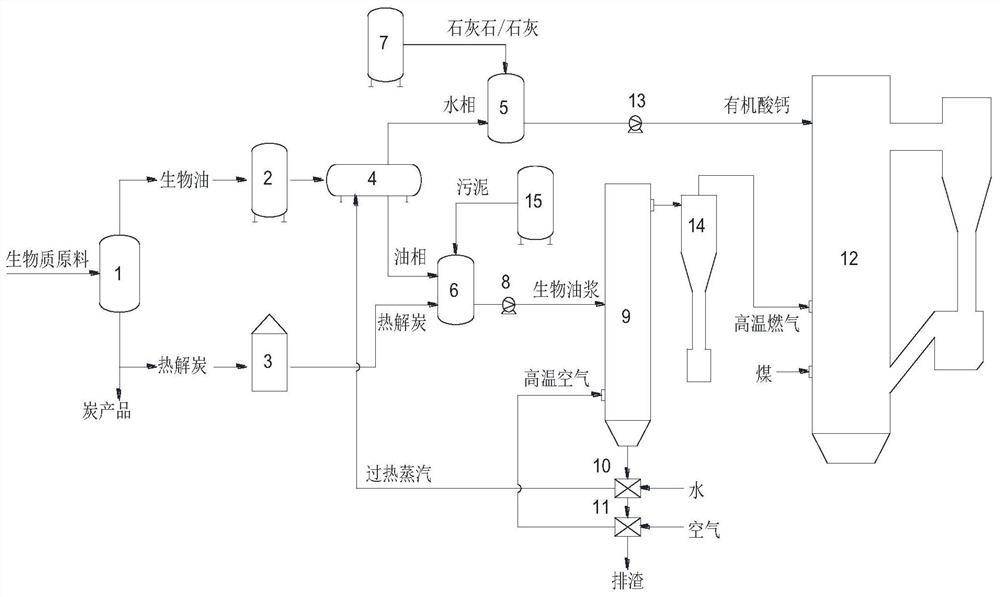

[0056] Such as figure 1 As shown, a coal-fired coupled biomass power generation system and method provided in an embodiment of the present invention includes a biomass pyrolysis unit, a storage and processing unit, a pressurized gasification unit and a coal-fired power generation unit. Among them, the biomass pyrolysis unit 1 is close to a site rich in biomass raw materials, and pyrolyzes the biomass raw materials on-site or nearby to produce bio-oil and pyrolytic charcoal, and a mobile pyrolysis device can also be used. At the same time, part of the pyrolytic charcoal can be processed into high value-added charcoal products, increasing the economic benefits of the pyrolysis unit. Then the bio-oil and pyrolytic charcoal are sent to the oil tank 2 and the charcoal bin 3 of the storage and processing unit of the coal-fired power plant for centralized storage. The oil tank 2 is connected with the oil-water separator 4, and the bio-oil is separated into water phase and oil phase ...

Embodiment 2

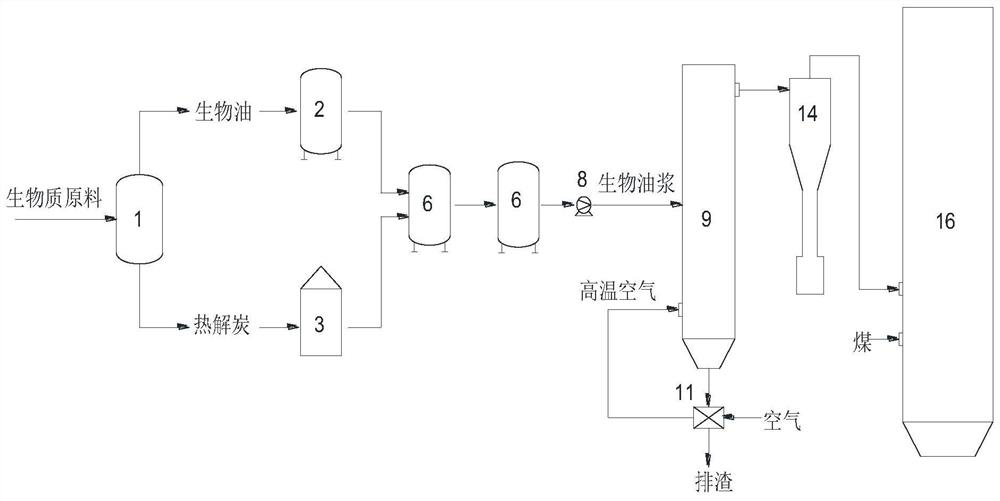

[0058] Such as figure 2 As shown, the operation mode of the biomass pyrolysis unit is consistent with that of Example 1, the difference is the furnace type of the coal-fired boiler, which is a pulverized coal boiler in this example.

[0059] The biomass pyrolysis unit 1 is close to a site rich in biomass raw materials, and pyrolyzes biomass raw materials on-site or nearby to produce bio-oil and pyrolytic charcoal, and a mobile pyrolysis device can also be used. At the same time, part of the pyrolysis charcoal can be processed into high value-added charcoal products, increasing the economic benefits of the pyrolysis unit 1 . Then the bio-oil and pyrolytic charcoal are sent to the oil tank 2 and the charcoal bin 3 of the storage and processing unit of the coal-fired power plant for centralized storage. The bio-oil and pyrolytic carbon are prepared in the bio-oil slurry mixing tank 6, and the pyrolytic carbon and bio-oil are mixed at a mass ratio of 1: (2-10), and the particle ...

Embodiment 3

[0061] Such as image 3 As shown, a coal-fired coupled biomass power generation system and method provided in an embodiment of the present invention includes a biomass pyrolysis unit, a storage and processing unit, a pressurized gasification unit and a coal-fired power generation unit. Among them, the biomass pyrolysis unit 1 is close to a site rich in biomass raw materials, and pyrolyzes the biomass raw materials on-site or nearby to produce bio-oil and pyrolytic charcoal, and a mobile pyrolysis device can also be used. The bio-oil and pyrolytic carbon are stored in the oil tank 2 and the carbon bin 3 respectively, and the two are prepared in the bio-oil slurry tank 6, and the pyrolytic carbon and the bio-oil are mixed in a mass ratio of 1: (2-10) , Pyrolytic carbon particle size is less than 1mm. Then the bio-oil slurry is sent to the bio-oil slurry tank 6 arranged in the coal-fired power plant for centralized storage, and then sent to the pressurized gasifier 9 under the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com