Electrically responsive intelligent hydrogel, preparation method thereof, and manipulator type soft-bodied robot

A hydrogel and electroresponse technology, which is applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems such as the limitations of electroresponsive hydrogels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

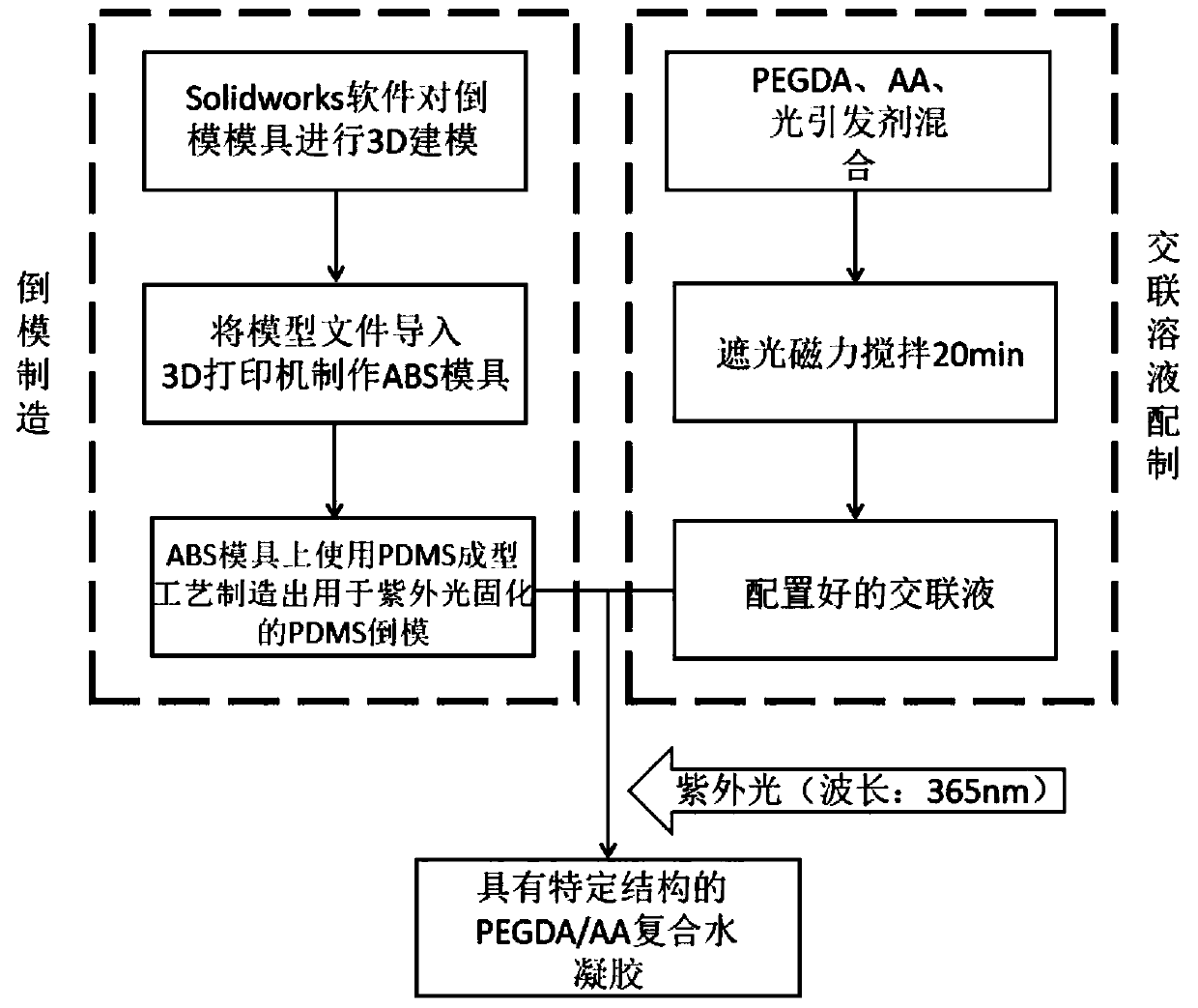

[0028] The present invention provides a method for preparing the electro-responsive smart hydrogel described in the above technical solution, comprising the following steps:

[0029] Polyethylene glycol diacrylate, acrylic acid, and photoinitiator were mixed and irradiated to obtain an electroresponsive smart hydrogel.

[0030] In the present invention, unless otherwise specified, the required preparation materials are commercially available products well known to those skilled in the art.

[0031] The invention mixes polyethylene glycol diacrylate, acrylic acid and photoinitiator. In the present invention, the photoinitiator is preferably phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide. In the present invention, the mass ratio of polyethylene glycol diacrylate, acrylic acid and photoinitiator is preferably 1:4˜16:0.01, more preferably 1:8˜12:0.01. In the present invention, the mixing process is preferably to first mix PEGDA and AA, then add a photoinitiator to the resultin...

Embodiment 1

[0046] Fabrication of electroresponsive smart hydrogel: Mix PEGDA and AA at a mass ratio of 1:16, then add photoinitiator (phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide, mass ratio of PEGDA 0.01:1), using a magnetic stirrer, the resulting solution was stirred in shading for 20 min to obtain a cross-linking solution;

[0047] Use Solidworks software to carry out 3D modeling of the PDMS inverted mold, and save the modeling file in STL. format; import the modeling file in STL. format into the 3D printer, and use ABS wire as the raw material to make an ABS resin inverted mold; On the ABS resin inverted mold, use the PDMS molding process to manufacture an inverted mold whose material is PDMS;

[0048] The cross-linking solution was injected into the inverted mold, and the inverted mold was placed under an ultraviolet lamp, and irradiated at 365 nm for 30 seconds; the PEGDA / AA electro-responsive smart hydrogel was obtained.

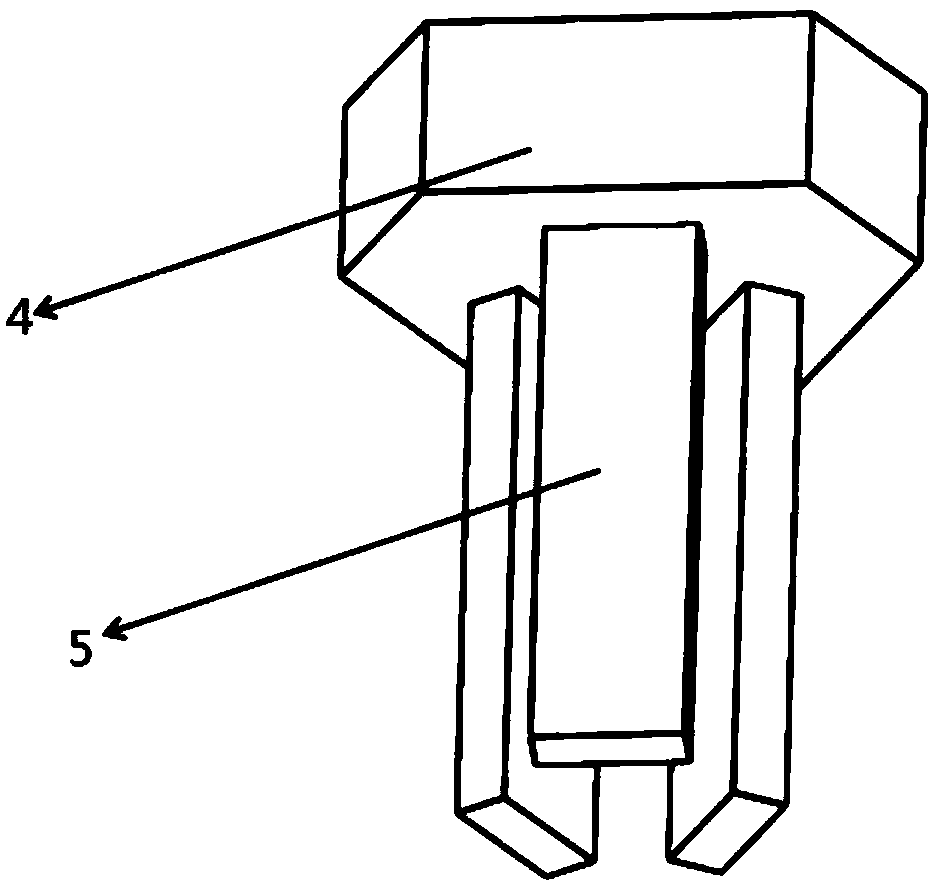

[0049] Support production: use Solidworks software to...

Embodiment 2

[0054] According to the scheme described in Example 1, the only difference is that the mass ratio of PEGDA and AA is 1:8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com