Method for preparing cyclohexanone by phenol hydrogenation

A technology for the preparation of cyclohexanone and hydrogen, which is applied in the hydrogenation preparation of aromatic hydroxyl compounds, carbon-based compound preparation, chemical instruments and methods, etc., can solve the problems of low conversion rate and selectivity, achieve convenient separation and improve economic efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

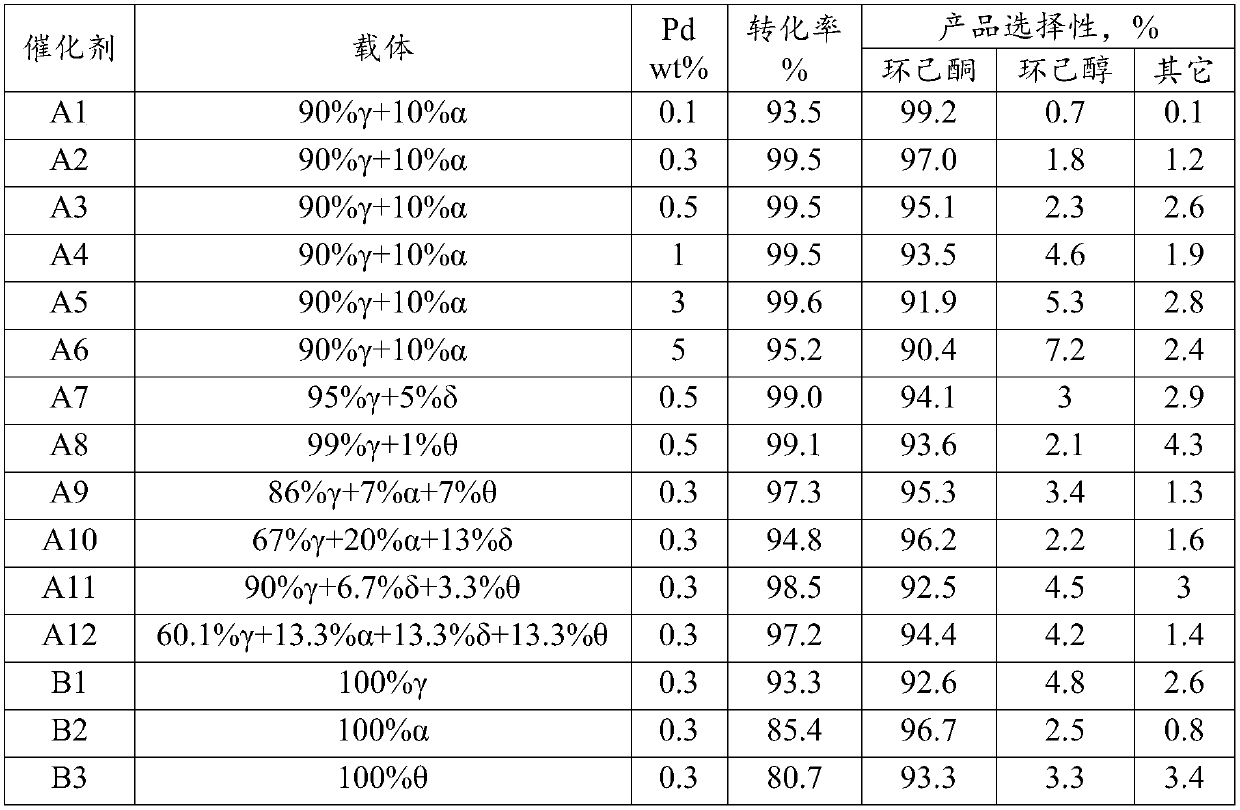

Examples

Embodiment 1

[0023] 27 g γ-Al 2 o 3 and 3 grams of α-Al 2 o 3 powder mixed with PdCl 2 The Pd / alumina catalyst (catalyst A1) was obtained by impregnating with an aqueous solution (w(Pd)=0.1%), drying and reducing.

Embodiment 2

[0025] 27 g γ-Al 2 o 3 and 3 grams of α-Al 2 o 3 powder mixed with PdCl 2 The Pd / alumina catalyst (catalyst A2) was prepared by impregnating with an aqueous solution (w(Pd)=0.3%), drying and reducing.

Embodiment 3

[0027] 27 g γ-Al 2 o 3 and 3 grams of α-Al 2 o 3 powder mixed with PdCl 2 The Pd / alumina catalyst (catalyst A3) was prepared by impregnating in an aqueous solution (w(Pd)=0.5%), drying and reducing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com