Film covering device for packaging box printing process

A packaging box and film-coating technology, which is applied in the field of carton film-coating equipment, can solve problems such as air leakage, easy residual paint, and inability to package the entire surface of the box

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

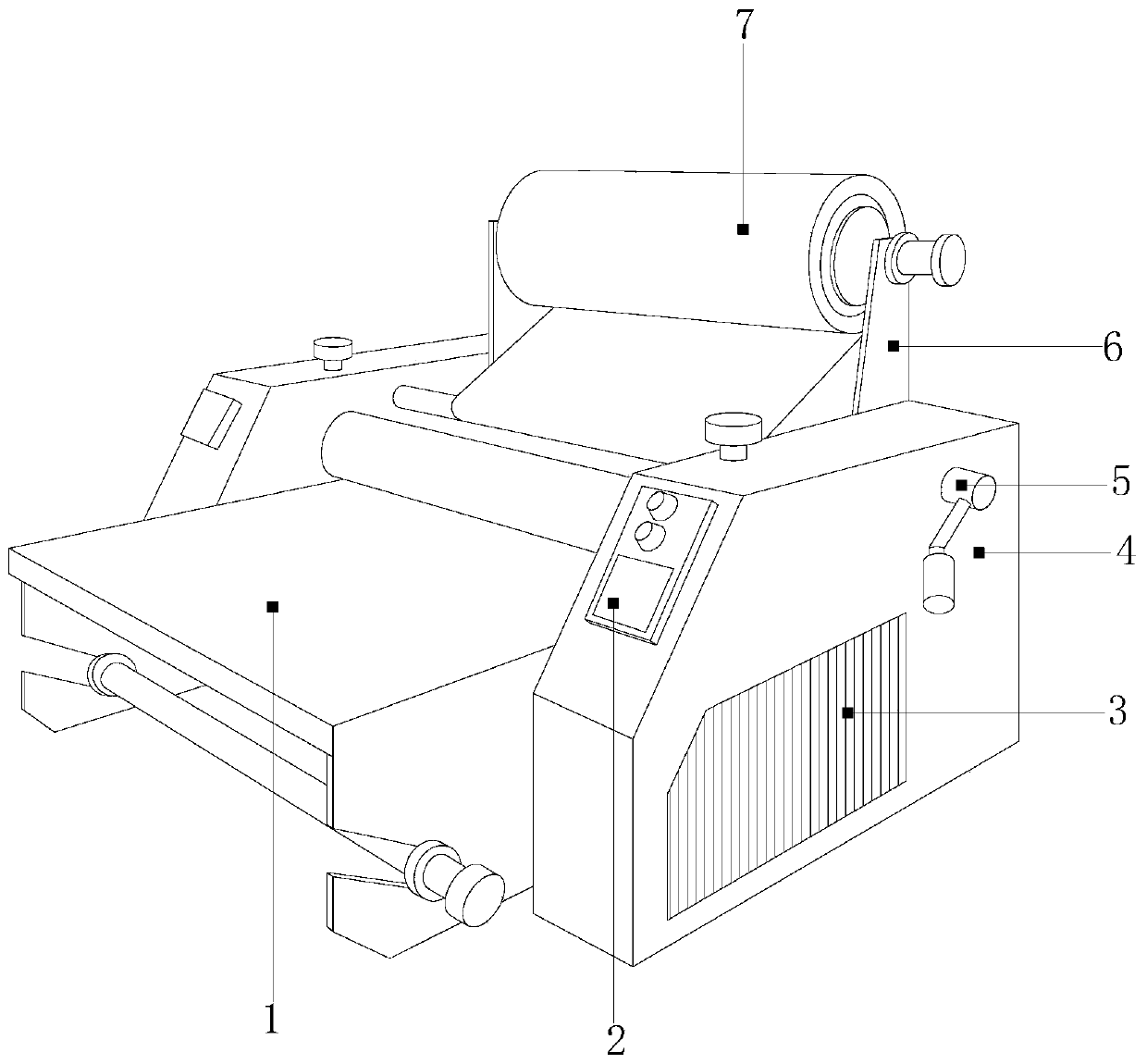

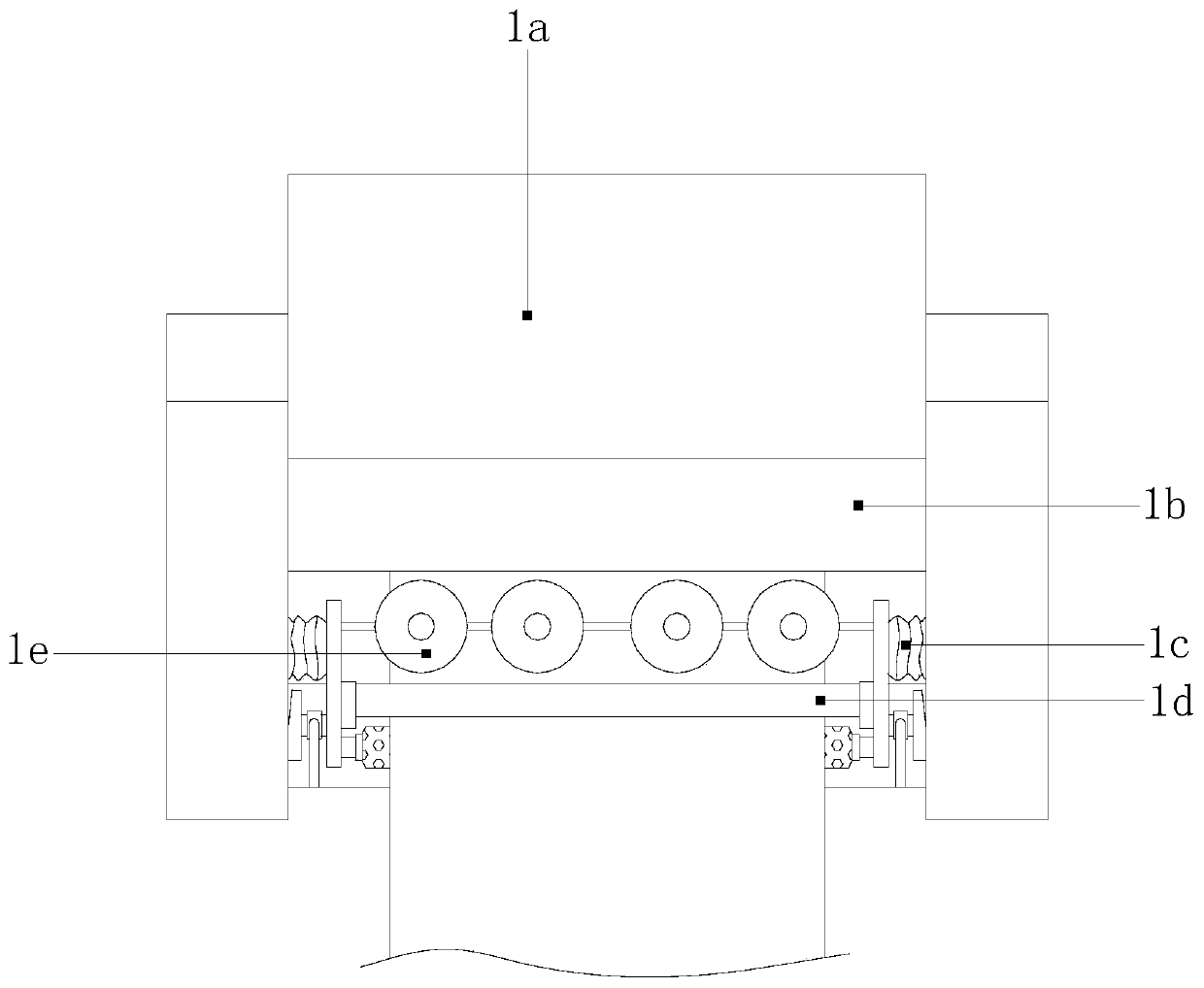

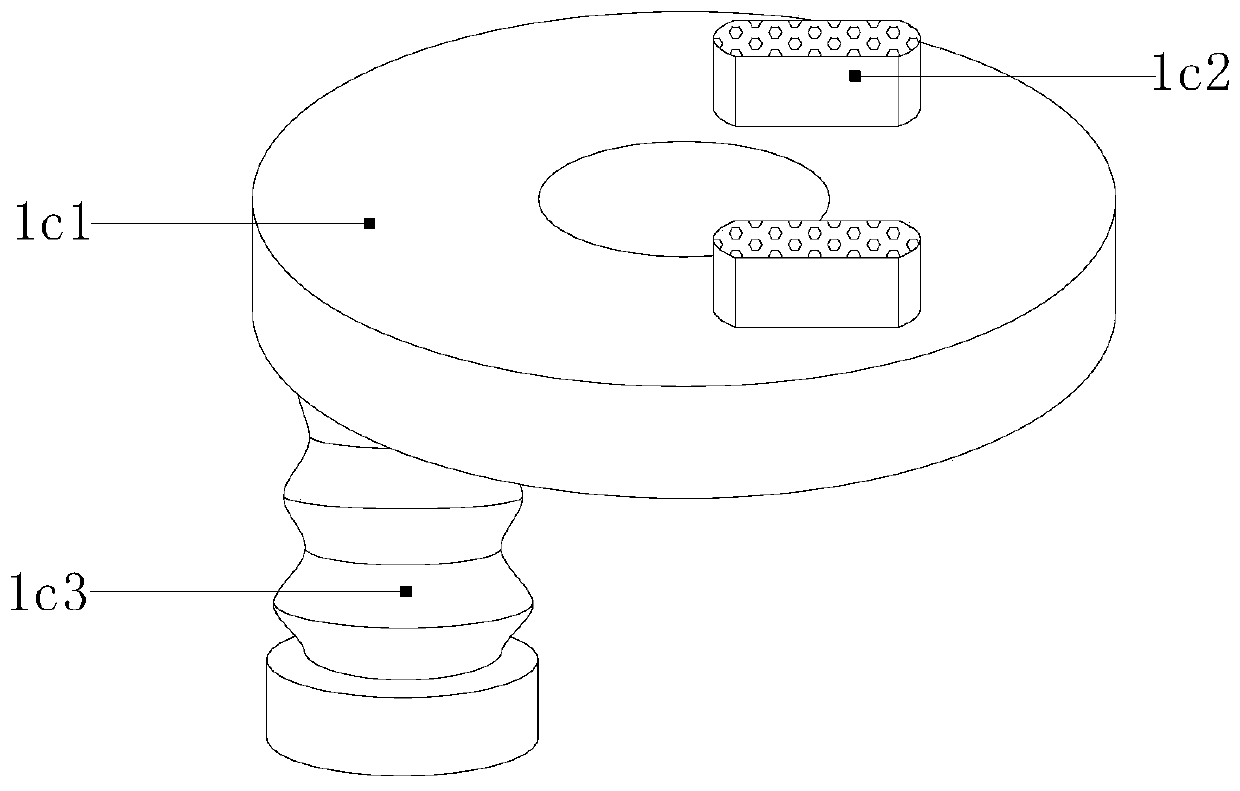

[0029] see Figure 1-Figure 6 , the present invention provides a film laminating equipment for packaging box printing process, its structure includes equipment platform 1, control panel 2, heat sink 3, equipment host 4, control handle 5, fixed bracket 6, film roll 7, said There are two equipment hosts 4, and they are installed on the left and right ends of the equipment platform 1 by buckling. The control panel 2 has a rectangular structure and is installed on the front top of the equipment host 4 by embedding. The lower end is provided with a cooling groove 3, and is an integrated structure, the control handle 5 is installed on the upper right side of the equipment host 4 by buckling, and the fixed bracket 6 is provided with two, and is installed on the equipment platform 1 by welding The rear ends on both sides, the two ends of the film roll 7 are respectively fitted and connected to the top of the fixed bracket 6, the equipment is started through the control panel 2, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com