Laser machining method and device for cooperative motion of laser galvanometer and air blowing device

A laser processing method and laser galvanometer technology, which are applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of low processing efficiency, difficulty in following the blowing device, and long waiting time for the blowing device. Improve the quality, reduce the difficulty of following, and reduce the effect of thermal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

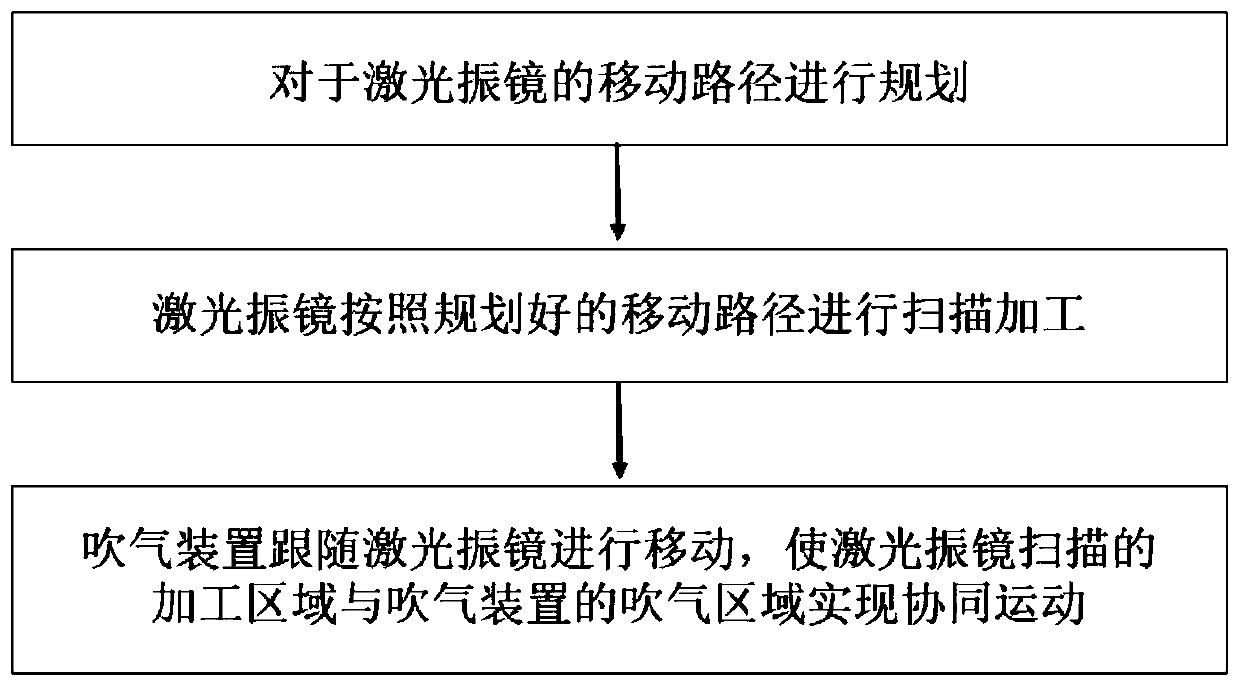

[0024] Such as figure 1 As shown, the present invention provides a laser processing method in which a laser galvanometer and an air blowing device move in concert, comprising the following steps:

[0025] S1. Planning the moving path of the laser galvanometer;

[0026] S2. The laser galvanometer scans and processes according to the planned moving path;

[0027] S3. The air blowing device moves following the laser galvanometer, so that the processing area scanned by the laser galvanometer and the air blowing area of the air blowing device realize coordinated movement.

[0028] Specifically, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com